|

Before silicon and germanium

semiconductors came online for use as diode rectifiers,

selenium was the material du jour. Selenium devices were widely

adopted for use as bridge rectifiers in power supplies and as detectors in AM radios,

where applicable, in place of vacuum tubes. At the time, they were not particularly

cheaper to implement, but there was an advantage in greater ruggedness, longer lifetime,

and lower power consumption (no heater element or high bias voltage required). Electronics

magazines of the era published many articles about selenium rectifiers, including

After Class: Working with Selenium Rectifiers,

The Semiconductor Diode,

New Selenium Rectifiers for Home Receivers,

Selenium Rectifiers,

Applications of Small High-Voltage Selenium Rectifiers, and

Using

Selenium Rectifiers.

Selenium Rectifiers

By S. Niciejewski, Sales Manager

Rectifier Division, Sarkes Tarzian. Inc.

The production of these units is carefully

controlled from the selection of raw materials to final testing. The production of these units is carefully

controlled from the selection of raw materials to final testing.

In appearance, selenium rectifiers are relatively simple devices; however, the

process and quality control under which rectifiers are produced are exacting and

critical. A one per-cent change in nucleation temperature or an additional few parts

per million of impurity in raw materials may disturb the balance enough to produce

poor results.

The basic materials required are few: selenium, aluminum, and a low melting point

alloy; however, the proper application and treatment of these is important. The

aluminum is a special alloy that will chemically etch and nickel plate properly

in an established process, and the selenium is very nearly 100 per-cent pure; impurities

are measured in parts-per-million and the difference between 7 and 10 parts-per-million

may result in a poor selenium rectifier. The eutectic alloy used in the counterelectrode

is a combination of pure metals that consistently melts at the same temperature.

The first step in the process of manufacturing selenium rectifiers is to prepare

aluminum base plates by chemical etching and electroplating with a very thin "flash"

coat of nickel. The undercut etch serves as a mechanical means of bonding the selenium

layer to the base plate during the subsequent pressing operation. The nickel plating

governs crystal growth and orientation in the selenium layer.

High purity selenium is sprinkled over the nickel plated base plate in fine powder

form and is then subjected to high temperature and pressure in hydraulic presses

with electrically heated platens. The pressing operation not only causes the selenium

to adhere to the base plate but actually starts crystal nucleation in the selenium

which is amorphous when applied. This process is very critical and important since

poor adhesion of selenium to base plate will have adverse effects on useful life.

After the powder-press operation, selenium rectifier cells are placed in long

conveyor ovens for heat treatment that completes the crystallization process. Here

the selenium is completely converted to "metallic" form and the crystals are arranged

to cause rectification. During this heat process the temperature is exceedingly

critical; a one per-cent deviation could cause poor crystallization and consequently,

a poor rectifier cell. This heat treatment also forms a very thin "barrier layer"

on the selenium and it is believed that rectification is accomplished in this layer.

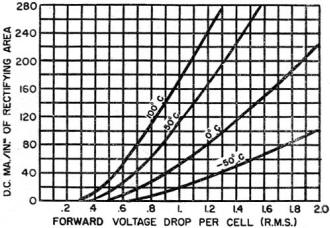

Fig. 1 - How the nonlinear characteristics of selenium rectifiers

contribute to high efficiencies even at large overload factors.

To produce cells with high inverse voltage ratings it is necessary to expand,

artificially, the barrier layer formed during heat treatment. This is accomplished

by applying a thin layer of organic lacquer especially developed for this purpose.

Under magnification, the artificial barrier layer forms a sponge-like surface, microns

thick, that increases the initial reverse or blocking resistance of the rectifier

and allows it to be increased even more during later operations.

To form a positive contact and current pick-up a low melting-point alloy is sprayed

over the barrier layer. The alloys used vary between manufacturers; however, those

in common use are alloys that range in melting temperature from 100° C to 175°

C.

When the alloy is applied the rectifier cell is virtually complete and will efficiently

rectify low voltages, approximately 10 volts r.m.s. per cell. However, since most

applications require relatively high voltages, the reverse or blocking resistance

of the rectifier must be increased substantially to be practical and this is accomplished

by subjecting rectifier cells to voltages that cause current to flow in the reverse

direction. This process, known as "electroforming," varies slightly, depending on

cell size, and usually requires approximately six hours to produce stable cells

with acceptable conductive and blocking characteristics.

After electroforming, cells are carefully checked for acceptability and placed

in stock for assembly into rectifier stacks. For rectifiers normally used in radio

and television receivers, stacks are immediately assembled and stocked because some

standardization has been reached; however, for commercial power-type rectifiers,

stacks are not assembled until orders are received, since most requirements are

custom designed and a very large number of combinations is possible.

Quality control plays a very important part in the production of selenium rectifiers.

Inspection stations are located at every step of the process and numerous tests

are made daily. Any indication of inferior quality causes an immediate shutdown

of the process line. Also, on completed rectifier stacks, life tests under adverse

conditions are continually in progress to determine quality, useful life expectancy,

and aging characteristics.

Extreme care and control are applied during the manufacture of selenium rectifiers

and units shipped into the field are of the highest quality possible to attain;

however, in spite of wide application, there are still reports from the field of

incorrect application where the rectifier is either caused to fail or is not producing

optimum results. It is well at this time to consider a few factors governing the

application of selenium rectifiers.

Application Notes

During the past five years, selenium rectifiers have found application in virtually

every phase of electronic and electrical equipment production. Typical applications

include radio and television receivers, communications equipment, business machines,

battery chargers, electroplating equipment, electrolysis equipment, cathodic protection

equipment, guided missiles, magnetic amplifiers, radar and sonar equipment, as well

as many special applications. Wherever d.c. power is either required or desirable,

selenium rectifiers will provide an economical and efficient method of conversion.

Fig. 2 - How reverse current increases as frequency is varied

from 20 to 15,000 cps.

In spite of widespread use, the selenium rectifier is still somewhat of a mystery

and enigma to the average engineer and technician.

Selenium rectifiers are thermally as well as electrically rated devices; therefore,

special precautions must be taken to insure long useful life under adverse conditions.

The rectifier stack should be mounted with the cells in a vertical plane so that

the convection of air is unimpeded. The stack should be mounted at the coolest location

on the chassis, away from heat dissipating equipment such as resistors, tubes, transformers,

ballasts, or any heat radiating element. If the ambient or surrounding temperature

is higher than 50° centigrade, stacks should be properly de-rated to insure

long, trouble-free life; however, de-rating is not as severe when relatively short

life (1000 hours minimum) is required. Since temperature presents a very complex

problem, particular applications should be referred to the manufacturer of selenium

rectifiers for individual consideration and recommendation. Following this procedure

will always result in the most economical design compatible with life and duty requirements.

Table 1 shows general de-rating factors; however, individual requirements may often

require deviation from the listed values.

To conserve space and decrease weight, many design engineers take advantage of

forced air cooling. A sufficient volume of air to limit operating temperatures allows

a 250 per-cent increase in d.c. load current.

For example, a rectifier that is rated at 10 amperes with normal convection cooling

can be operated at 25 amperes if sufficient air is passed between the cells. Also,

to decrease the effects of very high ambient temperatures, forced air is often used

to allow higher percentages of normal rating. In all cases, the recommendations

of the manufacturer should be followed.

The efficiency of conversion in selenium rectifiers is relatively high, usually

on the order of 90 per-cent in three-phase, full-wave circuits and 70 per-cent in

single-phase, full-wave circuits. The nonlinear characteristics of selenium rectifiers

contribute to high efficiencies even at large overload factors. For example, in

Fig. 1, it is evident that there is only a 10 per-cent decrease in the efficiency

of a three-phase, full-wave circuit as the load is varied from 50 per-cent to 300

per-cent of normal, and only 7 per-cent under the same conditions in a single-phase,

full-wave circuit. This information is important to the design engineer who plans

to use overload factors with forced air cooling.

Table 1 - Derating factors on selenium rectifiers. Note that

these factors are based on long life requirements of the units.

By the very nature of its construction (two metals separated by a semiconductor)

selenium rectifiers have a considerable amount of inherent capacity. This capacity,

approximately 0.1 to 0.15 microfarad-per-square-inch of rectifying area, limits

the freque-cy at which rectifiers can be used. The practical frequency limit varies

between 1000 and 15,000 cycles-per-second, depending on cell size and electrical

requirements. In general, in applications that require small values of d.c. current,

the maximum practical frequency is 15,000 cycles-per-second; and 1000 cycles-per-second

in applications where relatively large d.c. load currents are required. Operation

of the rectifier at frequencies above the practical limit results in sharp reduction

of the rectification ratio (reverse to forward impedance) and efficiency, due to

increased reverse current. Fig. 2 shows the increase in reverse current as

the frequency is varied from 20 to 15,000 cycles-per-second.

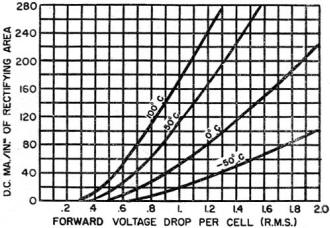

The minimum voltage at which a rectifier will pass measurable amounts of d.c.

current in the forward, or conducting, direction is known as the threshold voltage.

Depending on temperature, the threshold voltage in a selenium rectifier will vary

between approximately 0.25 volt at high temperatures and 0.6 volt at low temperatures.

This characteristic excludes the use of selenium rectifiers in applications where

very low voltages are required; typical of these are measuring instruments and some

control circuits. To insure proper operation and stability the r.m.s. voltage should

be a minimum of 1 volt. On the other hand, many applications have been developed

around this threshold voltage characteristic and selenium rectifiers are being used

as filament voltage regulators and as protective shunts across sensitive instruments.

Fig. 3 shows typical isothermal characteristics and values of threshold voltages

at various temperatures.

Fig. 3 - Graph of typical isothermal characteristics of

selenium rectifiers and threshold voltages at various temperatures.

When operated, and to a lesser extent when idle, selenium rectifiers will age;

that is, with a constant a.c. input voltage, the rectified d.c. output voltage is

higher when the rectifier is first installed than it is after a period of operation.

The average decrease in output voltage after 10,000 hours of operation under normal

conditions is approximately 5 per-cent, most of which occurs during the first few

thousand hours. In applications where the d.c. voltage requirements are extremely

critical, the transformer used should be provided with "aging" taps that will increase

the a.c. input voltage to the rectifier by 5 to 10 per-cent. By this method any

aging of the selenium rectifier can be compensated by increased input voltage.

Selenium rectifiers can be overloaded for their current output under momentary

or cyclic conditions without serious damage; however, a prolonged overload such

as caused by a short circuit will damage the rectifier. Fuses or other protective

devices should be used wherever possible and the cause of trouble corrected before

power is applied to the rectifier.

Overvoltage conditions are more serious than current overloads. A potential in

excess of rating may cause a breakdown across the selenium layer and while a selenium

rectifier is "self-healing" to an extent, prolonged over-voltage conditions will

cause rectifier failure. If an overvoltage condition occurs and the breakdown across

the rectifier is sustained the odor of selenium fumes can be detected and power

should be turned off immediately to minimize the damage. Cause of the overvoltage

condition should be determined and corrected before the power is turned on again.

Typical circuits in popular use and a brief explanation of each follows:

Fig - 4. Six common circuits in which selenium rectifiers are

used, together with approximate wave shapes under resistive load, ripple frequency,

ripple percentage and approximate a.c.-d.c. ratio. (A) Half-wave, single-phase,

(B) bridge, single-phase, (C) centertap, single-phase, (D) half-wave, three-phase,

(E) bridge, three-phase, and (F) centertap, three-phase.

Single Phase

Half Wave (Fig. 4A): Half-wave rectification is generally used in applications

that require little power. Most popular applications have been in radio and television

receivers to deliver "B+" power. The ripple frequency is the same as the supply

frequency and the ripple component is large since the rectifier conducts only during

one half of the input cycle. Special transformer design is required because of unidirectional

flow of d.c. current through the secondary.

Bridge (Fig. 4B): The single-phase bridge rectifier is popular because it

offers flexibility of design, full-wave rectification, ripple frequency twice source

frequency, high efficiency, and utilization of an economical transformer design.

Its fields of application cover every phase of electronic and electrical design.

Center Tap (Fig. 4C): As in the bridge circuit, the ripple frequency and

efficiency are high; however, the transformer design is more complicated. The full-wave,

centertap circuit is commonly used in low voltage applications (less than 10 volts

d.c.) such as laboratory electroplating and battery charging equipment.

Three-Phase

Half Wave (Fig. 4D): The three-phase, half-wave connection is primarily

used in low voltage high current applications. The output ripple frequency is three

times the source frequency and the load ripple component is approximately 20 per-cent.

The three-phase, half-wave rectifier is commonly used in commercial electroplating

applications that require thousands of amperes of current.

Bridge (Fig. 4E); The three-phase bridge is the most economical and useful

circuit where d.c. power requirements are high and efficiency is an important factor.

The ripple frequency is six times the source frequency and the load ripple component

is only 4.5 per-cent. In most applications filtering is not required. Popular applications

include aircraft motor starters, electrolysis equipment, large power supplies, and

arc welding equipment.

Center Tap (Fig. 4F); The three-phase, centertap circuit is used where d.c.

voltage requirements do not exceed 15 volts and load current requirements are high.

Special transformer design is required to provide a six-phase secondary. This connection

is used to some extent in electroplating equipment.

In addition to the popular circuits discussed, selenium rectifiers are used in

many special applications that take advantage of characteristics peculiar to selenium

rectifiers. Typical of these are voltage regulators, spark quenchers, protective

shunts, polarizing circuits, magnetic and capacitive field discharge, and d.c. blocking.

A few precautions which must be taken when using selenium rectifiers include:

1. Do not use an ohmmeter to test rectifiers. The nonlinear resistance inherent

in selenium rectifiers will give erroneous results.

2. Do not loosen the rectifier stack assembly.

3. Take care to keep solder and soldering irons from contacting rectifier cells.

4. Do not install selenium rectifiers with open construction in explosive atmospheres.

5. Even though the rectifier is rugged and can stand abuse, do not subject stacks

to severe shock or dropping.

6. Do not expose rectifiers to concentrated mercury vapors.

7. Mount rectifiers away from other heat radiating components .

8. Take8. Take special precautions at extremely high and low temperatures.

A good policy to establish is to contact a manufacturer of selenium rectifiers

whenever there is any question regarding application or design. Competent engineers

and modern laboratory facilities are available to solve your problem.

Posted April 7, 2023

(updated from original post

on 12/9/2016)

|