|

April 1955 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

X-ray inspection capability

is a vital tool not just in medicine but in industry. During my tenure with a major

cellphone power amplifier company as an RF Applications Engineer, I relied heavily

on x-ray imaging for many of the teardown reports that I wrote on competitors' products.

It included everything from determining metal layers in integrated circuits to deducing

multi-layer ceramic PCB routing lines and distributed components to just getting

a quick look inside a shielded enclosure without needing to disassemble it. A skilled

x-ray technician can make a huge difference in the quality of information that can

be gleaned from the images since angle, power level, and focusing takes a deft touch.

My first experience with using x-rays for inspection was while doing automated test

system design for production base station equipment companies. Very stringent PIM

(passive intermodulation) specifications were required for high power filters in

order to minimize 3rd and higher level intermods. The N-type connectors ended up

being the Achilles' heel of the switching filter matrix, and we had ordered a large

quantity from one highly qualified manufacturer. Quite a few needed to be returned

to the factory for rework because of failed intermod tests. The relationship got

a bit contentious after a while. One problem ended up being that the connectors

were supposed to have staking pins to guarantee that the connector body could not

turn during torqueing. The vendor swore to me that their inspection process was

so perfect that there was no way any could have been missed. Fortunately for me,

the company I worked for also happened to manufacture x-ray tubes and had an x-ray

machine for testing the tubes. I had the production test technician slide one of

my suspect filters into the machine and sure enough, the filters that had the stainless

steel pins installed showed in high contrast to the aluminum filter cases. I then

had a way to verify every filter, which was not possible with only a visual inspection

because an epoxy backfill material was placed into the staking pin hole.

X-Ray Inspection

Ed Bukstein Ed Bukstein

Penetrating powers of x-rays help industry probe secrets of materials and new

products.

X-rays are similar to radio waves in that they are electronically produced, are

invisible, and travel at the speed of light. X-rays, however, are in the extremely

high frequency range and have very short wave-lengths. Even the shortest of radio

waves, the so-called "microwaves" - are gigantic by comparison. A typical wavelength

of x-ray radiation is 0.0000000001 meter (one ten-billionth of a meter). These extremely

short wavelengths have great penetrating power, and can pass through substances

which light cannot penetrate.

Besides their well-known use in dental and medical examinations, x-rays have

many industrial applications. For example, x-ray apparatus is used to detect internal

flaws in metal castings, check packaged foods for presence of foreign particles,

inspect welds, check the alignment of elements in electron tubes, check the centering

of the wire in insulated cables, etc.

Anode of this gigantic x-ray unit gets one million volts. G-E built it for Sutter

Hospital, Sacramento, California.

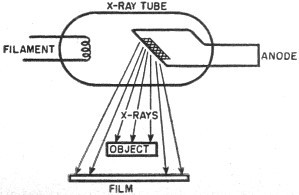

As shown in the diagram, the x-ray tube is basically a diode. Electrons emitted

from the filament are attracted down the length of the tube to the copper anode.

The anode contains a tungsten insert which acts as a target for the electrons. Traveling

at a very high speed, the electrons strike the target, producing the x-rays. To

give the electron stream its high velocity, a large amount of voltage must be applied

to the tube. Plate voltages as high as two million volts have been used in commercial

x-ray units.

Electrons from filament hit anode at high speed; resultant radiation

creates x-rays.

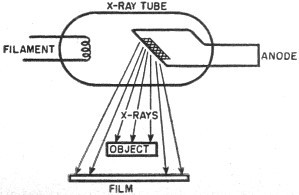

The object to be x-rayed is placed between the x-ray tube and a sheet of photosensitive

film. The x-rays penetrate the object and strike the film. This action produces

a shadow image of the internal structure of the object. For example, if the object

being examined is a pulley belt with internal reinforcement wires, the x-rays will

pass easily through the rubber portion of the belt, but will be obstructed by the

wires. The developed film will therefore show an image of the wires (see photograph

above).

In some applications, speed of inspection is an important feature and the time

required to develop the film introduces an objectionable delay. In these cases,

a fluorescent screen is used instead of the film. Such screens glow where they are

exposed to x-rays, and thus produce an immediate image. An installation of this

type is known as a fluoroscope.

Posted September 21, 2022

(updated from original post

on 10/14/2013)

|