|

June 1963 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

What is capable of putting

out more power, a solid state amplifier or a vacuum tube amplifier? The simple answer

is that given a large enough array of power combiners, a solid state power amplifier

can theoretically put out as much power as a tube amp, but the complexity is much,

much greater. A single vacuum tube can output RF power levels in the megawatt range,

but even the highest power GaN (gallium nitride) semiconductor devices do not reach

the kilowatt realm. That is the reason there are still so many vacuum tube transmitters

- the tubes themselves - still being produced today. Equivalent size solid state

transmitters are generally much larger because of the huge number of individual

power amplifier modules and massive power combiners needed. The great advantage

of solid state PA (SSPA) systems is the elimination of a single point failure. Output

power is degraded gracefully rather than catastrophically and maintenance is vastly

simpler since most individual SSPA modules are hot-pluggable, meaning the system

continues to operate in a crippled state while failed parts are replaced. There

is no new technology on the horizon that will change the equation, but don't be

surprised if some form of graphene surfaces as the new wonder power amplifier material.

Here you can read Part 1,

Part 2

and Part 3.

The Tube Family Tree, Part 2

The "second generation" of vacuum tubes,

offsprings of the first simple types, found new jobs to be done The "second generation" of vacuum tubes,

offsprings of the first simple types, found new jobs to be done

By Louis E. Garner, Jr.

In the early days of radio, essentially the same tubes were used for both transmitters

and receivers. Even today, although transmitting tubes are considered a distinct

class, there is a considerable overlap between higher power receiving and lower

power transmitting tube types - in construction, in design, and in electrical characteristics.

Hams, for example, frequently use receiver power tubes, such as the 6L6, in their

radio transmitters. The low-power transmitting tube does not differ appreciably

in appearance, size or power-handling capacity from the tubes used as horizontal

deflection amplifiers in television receivers.

There is also a good correlation between transmitting and receiving tubes as

far as generic types are concerned. Both classes can be divided into such groupings

as diodes, triodes, tetrodes, pentodes, and beam power tubes. Both filamentary and

indirectly heated cathodes are used in each class. The tube electrodes have the

same designations - plate, grid, cathode, and so on - in both. And the same general

characteristic terms are used in describing both.

When we turn to specifics, on the other hand, we find that there is a considerable

difference between transmitting and receiving tubes. Transmitting types, in general,

are constructed of sturdier materials, and, as a result, are larger, heavier, and

more expensive than their receiving type counterparts.

Two extreme examples may be helpful.

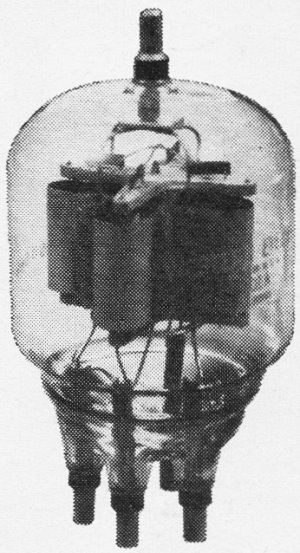

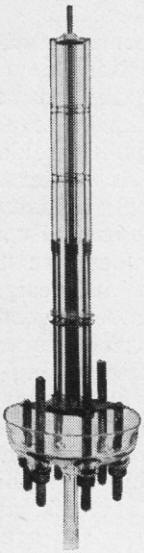

This is a typical transmitting tube, by Westinghouse. Plate is

made of graphite.

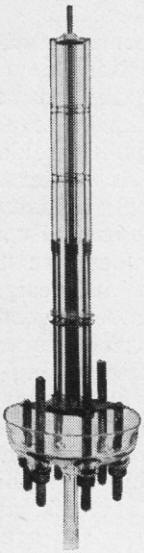

Components of a high-power Federal Telephone & Radio transmitting

tube. Electrodes are heavy and special insulation is used to withstand high voltages

and heat; heavy-duty terminals take care of high currents. Tubes of this general

type may be forced air-cooled or water-cooled. (above and below left)

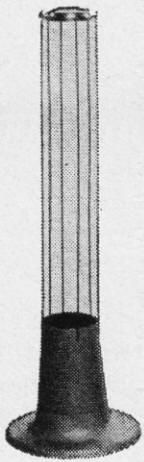

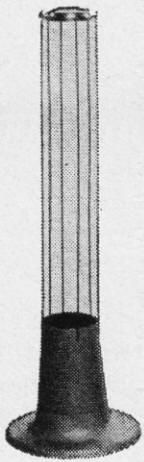

Designed for forced air-cooling, this Amperex

high-power transmitting tube has a finned radiator fitted over the plate.

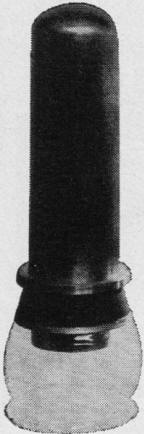

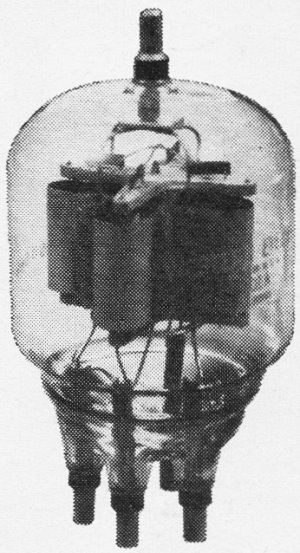

Multiplier-type phototube. General Electric version.

The 6AQ5 is a typical beam power receiving tube, while the RCA 2039 is a high-power

shielded-grid beam triode transmitting tube. The basic specifications of the 6AQ5

include: filament voltage, 6.3 volts; filament current, 0.45 amps; peak positive-pulse

plate voltage, 1100.0 volts; peak plate current, 0.115 amps; average plate current,

0.040 amps; and plate dissipation, 10.0 watts. The same basic specifications of

the 2039 are: filament voltage, 7.3 volts; filament current, 1140.0 amps; peak positive-pulse

plate voltage, 40,000.0 volts; peak plate current, 92.0 amps; average plate current,

5.7 amps; and plate dissipation, 150,000.0 watts. These comparative specifications

emphasize the primary difference between transmitting and receiving tubes: their

power-handling capacity.

To obtain high powers, very high voltages and currents are required. This means

that the tube's electrodes must be very heavy in order to handle the large currents

without melting, and widely separated to prevent arcing at the high voltages. (Arcing

can destroy a tube.) Special insulation must be used where the electrodes are mounted

to withstand a combination of high heat and tremendous voltages. And, of course,

heavy-duty terminals are needed to handle the currents. Finally, all of the above

construction factors must be taken into account and balanced against the tube's

designed operating frequency (which may require close spacing) and desired electrical

characteristics.

While maximum electrical ratings, amplification factor, mutual conductance, and

similar characteristics are all important, the transmitting tube's most important

single characteristic is probably its rated maximum plate dissipation. Specified

in watts (or kilowatts), this is directly proportional to the amount of power that

the tube can handle and hence the r.f. power it can deliver.

In practice, the tube's actual plate dissipation is the difference between its

d.c. plate input power (plate voltage multiplied by average plate current) and its

r.f. output power. For example, if a Class C r.f. power amplifier is 70% efficient

and has a d.c. input of 10 kw. (5000 volts at 2 amperes, say), it will deliver 7

kilowatts r.f. (approximately) and will have a plate dissipation of 3 kw.

With plate dissipations running into the kilowatt range for some types of tubes,

it is obvious that a means must be provided for removing the heat generated if the

tube is to be kept from melting. While lower power transmitting tubes are invariably

convection air-cooled, higher power types are either forced air-cooled or water-cooled.

Medium-power tubes are often provided with radiating fins, while high-power types

are equipped with water jackets. The cooling device, whether a radiating fin system

or a water jacket, may be either an integral part of the tube or a separate accessory.

Industrial Tubes. Except for a few special types, industrial

electron tubes correspond in most ways to their receiving and transmitting tube

counterparts. Low-power receiving types are used in industrial controls, alarm circuits,

counters, protection devices, and similar equipment, while transmitting types are

found in high-voltage and high-current power supplies, welders, and induction and

dielectric heaters.

In general, industrial receiving type tubes, while basically similar to ordinary

receiving tubes, are usually of sturdier construction and designed for continuous

operation under rigorous physical conditions. Industrial tubes, as a rule, must

have extremely long filament life, for equipment shutdowns - even for short periods

- can be extremely costly to a manufacturer. In addition, the tubes must be able

to withstand extremes in temperature, shock, and vibration.

Gas-filled tubes are used extensively throughout industry. Thyratrons and cold-cathode

tubes are utilized for motor, electromagnet, and solenoid control, while mercury

vapor rectifier tubes are employed in heavy-duty d.c. power supplies for electroplating,

electrolysis, and similar work.

There is one type of electron tube that is used in many industrial applications

but which is not, however, found in communications equipment: the ignitron. Used

for high-capacity switching and in heavy-duty d.c. power supplies for welding, motor

control, and certain electro-chemical processes, the ignitron is basically a special

type of cold-cathode tube in which mercury vapor is produced by a controlled electric

arc. In one sense, it is a type of rectifier. Some types are capable of handling

voltages as high as 20,000 volts and conducting currents as great as 35,000 amperes

for short periods.

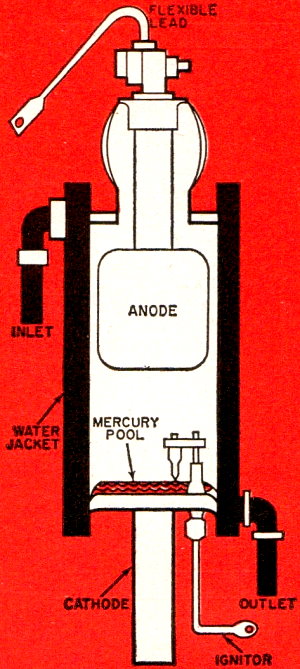

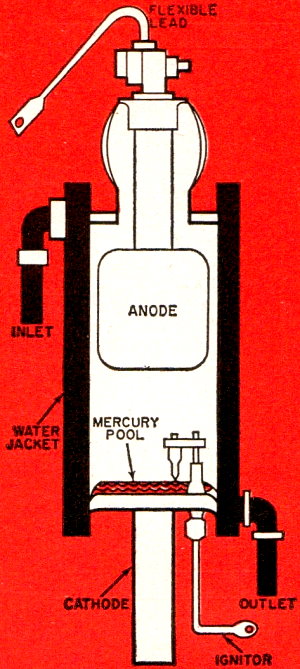

In its basic form, the ignitron consists of an evacuated metal envelope (which

may be double-jacketed for water cooling), a pool of mercury which serves as a cathode,

a heavy metal anode, and a special ignitor of rough-surfaced material which resists

"wetting" by the mercury but which projects into the pool of liquid metal.

In operation, the tube will not conduct until "fired" by current applied to its

ignitor electrode. A moderate-current pulse here creates high-current densities

at the rough points of contact with the mercury pool, establishing a hot arc which

vaporizes the mercury, filling the tube with vapor and allowing conduction to take

place between the cathode and anode. Afterwards, the anode-cathode current is sufficient

to keep the arc established and to maintain current flow.

Phototubes. When light falls on certain metals and metallic

compounds, such as cesium, cesium oxide, potassium, and zinc, electrons are emitted

from the material's surface. This photoemissive effect was first noticed, although

not fully understood, by Heinrich Hertz in 1887. Like many early discoveries, this

one eventually led to the development of the phototube: a light-sensitive electron

tube with an electrical output proportional to the amount of light falling on its

sensitized surface.

Phototubes are used extensively in both industrial and commercial applications

- burglar alarms, automatic door openers, electronic counters, doorway annunciators,

safety equipment for industrial machines, sound motion picture projectors, etc.

The phototube is a special type of cold-cathode diode. The cathode is generally

a semicircular metal plate coated with photo emissive metallic compounds, the plate

a small rod or wire. In operation, light falling on the cathode causes electrons

to be emitted. If a positive voltage is applied to the plate (or anode), these free

electrons migrate to it, producing a minute output current.

Like human eyes, phototubes differ in their response to light. While their current

output is directly proportional to light intensity, the current may vary considerably

with identical light levels in different colors. Depending on the types of photoemissive

compounds used, phototubes may be made more sensitive to infrared, ultraviolet,

or to the whole spectrum of visible light. Except for physical construction and

type of lead connections, the chief differences between phototubes are found in

their spectral responses.

Sometimes, a small amount of selected gas will be introduced in a phototube.

The gas ionizes and reduces the tube's internal cathode-anode resistance, permitting

it to deliver a greater current output for a given cathode illumination. Gas phototubes

have a higher sensitivity than high-vacuum types but are more easily damaged by

excessive voltages and are somewhat less stable.

Photomultipliers. Unfortunately, the current output of standard

phototubes is extremely small - on the order of a microampere or less at typical

illumination levels. This fact has led to the development of a class of special

phototubes called photomultipliers. Used in scintillation counters, automatic light

dimmers, and in similar applications, photomultipliers make use of the principle

of secondary emission (which we discussed in Part 1) to increase their current output.

The photomultiplier consists of a photoemissive cathode, a series of secondary

anodes called dynodes) and the output anode or plate. Depending on tube type and

physical design, the dynodes may be arranged in a circle around the cathode, or

in parallel lines behind the cathode, which is tilted at a small angle.

In electrostatic cathode-ray tubes, the electron beam is

deflected and focused by the internal elements.

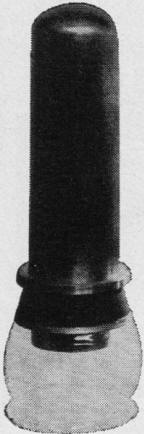

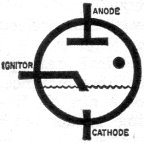

Details of the ignitron are shown above.

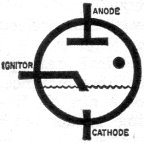

Schematic symbol for this industrial tube.

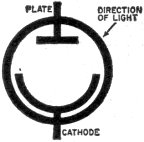

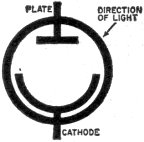

Basic phototube symbols. At left: the standard version. At right:

a photomultiplier.

A typical phototube, by General Electric./td>

Cathode-Ray Tubes. By definition, a cathode-ray tube (CRT) is

a device which utilizes cathode "rays," i.e., "rays" emitted by the device's cathode.

Cathode rays are, of course, streams of electrons.

Although often considered a relatively modern invention, cathode-ray tubes are,

historically, even older than more familiar electron tubes. Various types of cathode-ray

discharge and display tubes were used extensively in physics laboratories and schoolrooms

before the turn of the century, and as early as 1897 Karl Braun developed a cathode-ray

display tube very similar to modern television tubes.

TThe "heart" of most present-day CRT's is the electron gun. The gun is made up

of a filament, an indirectly heated cathode, a disc-shaped control grid, and disc-

or cylindrical-shaped focusing and accelerating grids (or anodes). Its purpose is

to produce a sharp stream of accelerated electrons. The number of electrons in the

stream (and hence its intensity, as well as the brightness of the spot it produces

when it strikes a screen) is controlled by the voltage applied to the control grid.

The beam's sharpness of focus is determined by the voltage relationships between

the focus and accelerating anodes.

In electromagnet CRTs, the beam is focused and deflected by magnetic

fields set u around the neck.

Display Tubes. Direct descendants of the early Braun tube, display

CRT's are used extensively in TV receivers and monitors, oscilloscopes, radar equipment,

and in a variety of test and research instruments. As the name implies, these tubes

serve to display electrical phenomena on a fluorescent screen, either as a line,

pattern, or reproduced picture.

In general, display tubes are made up of an electron gun assembly, a means for

focusing (if not contained within the gun itself) and deflecting the electron beam,

and a fluorescent screen. Manufactured in sizes ranging from tiny units with a 1"

-diameter screen to giant picture tubes with 30" screens, they are usually funnel-shaped.

The screen itself may be round, square, or rectangular. The envelopes or "funnels"

are made either of metal or glass, or a combination of both.

Most display tubes are identified by a combination numeral-letter type number.

The first number indicates the nominal size of the tube's screen, the first letter

(or letters) the particular tube, and the last letter and numeral the type of fluorescent

material (or phosphor).

Phosphors. Typically, a type 5BP1 tube has a 5" screen with

a type "P1" phosphor. Similarly, a type 20DP4 has a nominal 20" screen and a "P4"

phosphor. Cathode-ray tubes used as TV picture tubes generally have rectangular

screens and their size designation refers to a diagonal measurement across the face

of the tube. In some cases, TV picture tubes are called kinescopes.

An arbitrary system is used for identifying the various phosphors used. A type

P1 phosphor, for example, has green fluorescence and medium persistence; you'll

find this type in most oscilloscope tubes. Type P4 phosphors have white fluorescence

and medium persistence, and are employed primarily in television tubes. Type P5

phosphors have a bluish-white fluorescence and very short persistence; tubes with

this type of phosphor are used for high-speed photography of electrical phenomena

having a short time duration. The P11 phosphor is similar to the P5 type, but has

a slightly longer persistence.

Types P7 and P14 are both two-layer phosphors. The P7 type has a long persistence,

first emitting a bluish light, then a greenish-yellow. The P14 type has medium persistence,

first emitting a bluish, then an orange light which persists for over a minute.

These two types of phosphor are useful in instruments employed to observe low-speed

recurrent and non-recurrent phenomena. The last type of phosphor, P15, has a very

short persistence in the near ultra-violet region, emitting a visible blue-green

light afterwards; its principal application is in flying-spot scanner tubes.

Electrostatic and Electromagnetic. Electrostatic CRT's are those

which employ electrostatic fields to move the electron beam obtained from the gun

assembly. Electron beams may also be deflected by magnetic as well as electrostatic

fields, however. Most TV picture tubes are electromagnetic types.

In many cases, the beam may be focused as well as deflected by magnetic fields,

with a permanent magnet or electromagnetic coil placed around the tube's neck near

the gun assembly. In some tubes, the electron gun is aimed at an angle, rather than

straight towards the center of the screen, so that gas ions (in the cathode beam)

which may be produced are sent to one side and do not strike the screen (where they

could cause a damaging "burn"). Where this technique is used to "trap" ions, a separate

ion trap magnet restores the lighter electron beam to its straight-line path before

deflection.

Some CRT's combine the basic operating features of both electrostatic and electromagnetic

types. Electrostatic focusing may be employed, for example, by using a suitable

electron gun, with electromagnetic means used for deflecting the beam.

Cathode-ray tubes designed for color television receivers are basically similar

to the tubes described above, except that several electron guns are employed and

a special screen is used which fluoresces in the three primary colors: blue, green,

and red. The screen itself is made up in a repetitive triangular pattern of small

phosphor dots and protected by a mask, aligned so that each of the electron guns

excites only its particular phosphor (blue, green, or red).

Flying-Spot Scanner. The flying-spot scanner is a special type

of display tube, similar to more conventional CRT's except for its phosphor. In

general, it is used in conjunction with picture transparencies (such as motion picture

film or slides) and a phototube to produce a sequential electrical signal (or video

signal) which can be televised or used to reproduce the original picture.

In operation, a raster, or rectangular light pattern of fixed intensity, is formed

on the flying-spot scanner's fluorescent screen as the spot of light produced by

the electron beam "flies" across the screen. This moving spot of light is transmitted

through the transparent film to the phototube, where it develops a varying electrical

signal, dependent on the film emulsion density at each spot and hence on picture

content. The video signal obtained from the phototube is similar to that produced

by a TV camera and is used in the same way.

(to be continued)

PostedNovember 30, 2021

(updated from original post on 3/31/2014)

|