|

April 1959 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Before there were CFL light

bulbs with complicated electronic circuits for generating the requisite high voltages

without a transformer, there were just the familiar straight (and sometimes circular)

fluorescent bulbs that use a simple ballast arrangement and a built-in switch in

the bulb base. As with compact fluorescent (CFL) lights, very few people understood

how they worked. Most knew that the 8-foot-long T-12 bulbs (the large diameter ones

used in commercial buildings) made a really cool implosion sound when they broke

- usually intentionally (by people like me) since the glass tubes are amazingly

tough. I remember many moons ago, between high school and the time I enlisted in

the USAF, while I was an apprentice electrician working on a renovation job at a

public school (I took

electrical vocational courses for 3 years in high school), a co-go-fer and I

spent weeks wiring fluorescent fixtures all throughout the building. We worked atop

a tall scaffolding that was on wheels, pulling ourselves around the room by grabbing

the suspended ceiling grid. When the foreman wasn't around, we relieved our utter

boredom by "accidently" dropping the fluorescent bulbs onto the concrete floor.

If done just right so that the bulb hit the floor in a perfectly vertical position,

it would bounce up two or three feet and implode in mid-air. The acoustics of the

big, empty room, devoid thus far of sound-absorbing ceiling tiles, really enhanced

the effect... but I digress. This article does a nice job of explaining how the

non-curly-Q fluorescent bulbs work - with and without external starters.

The Electronics of Fluorescent Lamps

By Edgar D. Morgan By Edgar D. Morgan

Fluorescent lamps, once a novelty, are now an accepted part of the American scene.

Their gentle blue-white glow is encountered everywhere, from the tops of skyscrapers

to the depths of the New York subway system. However, the operating principles of

fluorescent lamps are little understood even by technicians.

Invisible Light. Many people know that fluorescent lamps are

among our most efficient light producers, and that they operate with a mercury vapor

arc. But few realize that over 80% of the radiation produced by that arc is in the

ultraviolet region and invisible to the human eye, and that every effort is made

to keep as much energy as possible in the invisible ultraviolet end of the spectrum.

Sounds foolish, doesn't it?

Cutaway view of a fluorescent lamp. All fluorescent lamps are

constructed as shown here. Only the glass tube changes in size and shape from model

to model.

The visible light actually comes from chemical compounds coated on the inside

of the glass tube. Called phosphors, these compounds have the property of emitting

visible light when they are excited by ultraviolet radiation. They have been termed

"light transformers" because of their ability to absorb energy at one wavelength

and radiate it at another.

The fluorescent lamp depends upon ionization for the production of the necessary

ultraviolet arc. Here's how it's done. The free electrons in the gas are accelerated

by an applied voltage, and each time a collision occurs between an electron and

a gas molecule, one or more additional electrons are displaced. These electrons

in turn, are accelerated enough to repeat the process on other molecules, and a

chain reaction takes place.

As each molecule returns to a stable state, it gives off its excess energy in

the form of radiation. It's the frequency of the radiation that determines whether

visible or invisible light will be obtained. In commercial lamps, the pressure of

the gas sealed in the lamp is adjusted very carefully so that nearly all of the

radiation occurs at one given ultraviolet wavelength, 2537 Angstrom units. This

frequency is selected for optimum excitation of the tube's phosphor coating.

Each chemical compound in the phosphor coating radiates light at a certain wavelength.

For instance, zinc silicate releases its radiation as green light, cadmium borate

radiates a predominately pink color, and calcium tungstate when excited gives off

blue light. By carefully blending these and other compounds, almost any desired

color can be obtained.

Warming to the Job. The electrons required to facilitate the

starting of the arc are provided by coated tungsten filaments in the ends of the

fluorescent tube - similar to the filament in an ordinary vacuum tube. Once the

arc is achieved, the heated filaments are no longer required and are automatically

switched off. A small amount of argon or krypton gas present in the tube facilitates

the initial arcing, which also serves to evaporate the globule of mercury in the

tube. From this point on, the arc is basically mercury vapor.

There are two pieces of auxiliary apparatus necessary to operate a fluorescent

lamp. One of these is a starter which acts as the automatic filament circuit switch

mentioned above. The second additional element required is the ballast, which serves

as a choke coil to regulate arc current as well as an autotransformer to provide

the high voltage kick needed to start the arc.

An Inductive Kick.

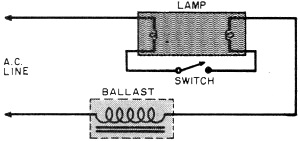

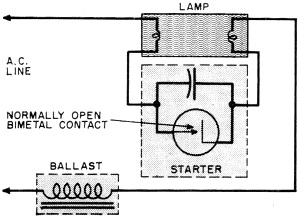

Fig. 1. Basic fluorescent lighting circuit in general use

only on small desk lamps. A manual switch performs the starting function.

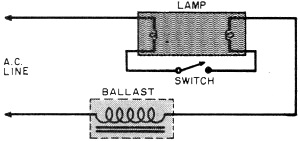

Fig. 2. This circuit is sometimes used to correct the poor

power factor in the circuit of Fig. 1. The ballast is shown here functioning

as autotransformer as well as choke coil.

The basic lamp circuit is shown in Fig. 1. When the switch is closed, the

ballast and the two filament windings are placed in series across the applied voltage,

and the filaments heat. When the switch is released a moment later, the inductive

kick of the iron-core ballast coil causes a momentary voltage surge across the lamp

which starts the arc. As the ballast is now in series with the lamp, the arc current

is limited by the impedance of the ballast. This simple circuit is widely used on

small desk lamps, but has too many disadvantages for general lighting use.

One of the disadvantages of the single lamp circuit is its poor power factor.

As the circuit is primarily inductive, due to the ballast, the current and voltage

have a phase relationship which makes for inefficiency in light output compared

to current drawn. A partial solution to this problem is the circuit shown in Fig. 2.

Here the starter is an automatic device although its function is the same as

the switch in Fig. 1. The power factor in this unit is improved by a shunt

capacitor. As a capacitor and a coil have an opposite effect on power factor, one

offsets the other; and the resistor serves to bleed off any charge which remains

on the capacitor. The circuit of Fig. 2 has been drawn to indicate that the

ballast is also serving as an autotransformer. The number and size of the lamps

used determines whether this is necessary or not.

Factors and Flickers. Another objectionable feature of the single

lamp circuit is its flicker, due to the 60-cycle line. Since incandescent lamp filaments

operate at a very high temperature, there isn't time for them to cool sufficiently

from cycle to cycle for the variation of light to be seen. The fluorescent lamp

must extinguish and restrike its arc 120 times per second as the voltage reverses

polarity. This causes a disturbing stroboscopic effect around machinery with cyclical

motion.

Probably the most common circuit in use today is shown in Fig. 3. This is

a two-lamp circuit and corrects several of the disadvantages inherent in single

lamp setups. The lamp indicated as inductive is connected in the same way as the

lamp in Fig. 1. The other lamp, however, has a capacitor in series with its

ballast. This serves to change its phase relations so that its current leads rather

than lags the voltage, and corrects the overall power factor. Thus, the two lamps

operate more efficiently as a unit.

Fig. 3. For the control of two lamps, this circuit is in

wide-spread use and has excellent power factor characteristics.

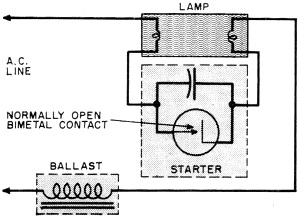

Fig. 4. Typical glow-type starting circuit used in home-type

fluorescent circuits.

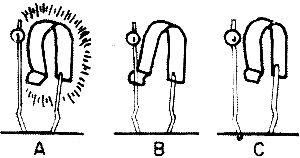

How a Glow Starter Works

The addition of this series capacitor, though, produces another problem. When

starting, the capacitive circuit sometimes limits the current required to preheat

the filaments. This effect is overcome by adding another compensating coil in series

with the starter on this lamp only.

Use of this type of two-lamp circuit is also beneficial in overcoming flicker.

Because the lamps operate out of phase, they reach their peaks of illumination at

different times and the combined light is relatively free from disturbance.

The Starter Story. One of the most fascinating pieces of auxiliary

equipment is the fluorescent starter. Its task is to close the circuit containing

the filaments when voltage is first applied, and after a preheating period of several

seconds, to open the filament circuit and keep it open as long as the lamp remains

on. A bimetallic strip is used which bends when heated, and serves as sort of a

time switch.

The most common type of starter is the glow starter. The entire unit is sealed

within a small glass envelope containing neon or argon gas and connected as shown

in Fig. 4. A bimetallic strip controls a contact which is normally open.

When first turned on, the full line voltage is applied across the glow lamp,

causing the gas to ionize and conduct. The heat of the ionized gas is sufficient

to cause the bimetal strip to close the filament circuit. The contact closing shorts

out the glow discharge and the bimetal begins to cool. After cooling (which takes

long enough to preheat the filaments satisfactorily), the contact within the starter

opens and the fluorescent lights. The starter is now across the lamp voltage, which

is not enough to ionize the neon gas, and so the unit is inoperative as long as

the lamp remains on.

The glow-type starter consumes no energy from the circuit after the starting

period is over. Its timing is not accurate, however, and as it is difficult to maintain

the proper gas pressure over a long period, sometimes the timing tends to become

very erratic.

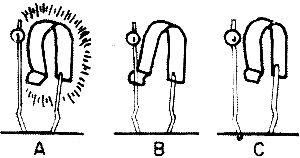

The line voltage produces a glow discharge between the bimetallic strip and the

fixed contact (A); the heat from the glow actuates the bimetallic strip, the contacts

close and the filament preheating begins (B); this shorts out the glow discharge,

the bimetallic strip cools and the contacts open (C). The resulting inductive kick

from the ballast then starts the tube.

A great many of our present-day starters incorporate modifications such as a

manual reset. If the lamp does not light after repeated attempts by the starter,

it ceases functioning until the trouble is corrected and the starter is reset by

pushing a spring-loaded button. There are others that use different contacts for

restarting so that it isn't necessary to wait for a bimetal strip to cool completely

before it can recycle.

The starter shown in Fig. 4 also contains a capacitor across the lamp contacts,

which acts to suppress radio interference.

Manufacturers of fluorescent lamps publish handbooks which elaborate on these

principles. They also give many more lighting circuits and their applications. The

very fact that fluorescent lamps are so readily accepted and so seldom studied in

detail is in itself a fine tribute to their efficiency and dependability.

Posted November 22, 2021

(updated from original post on 11/11/2013)

|