|

October 1959 Electronics Illustrated

Table of Contents Table of Contents

Wax nostalgic about and learn from the history

of early electronics. See articles from Electronics Illustrated, published May 1958

- November 1972. All copyrights hereby acknowledged.

|

A while

back, I posted a couple of articles on building simple

Tesla coils capable of producing a respectable electrical discharge arc.

They were completely passive devices and relatively safe. This Tesla coil design

from a 1959 issue of Electronics Illustrated magazine presents a model

that uses an 811A vacuum tube triode amplifier, and it can knock you on your

posterior. Believe it or not, 811A tubes are still readily available from many

sources, including

eBay

and DX Engineering,

and are quite popular for RF amplifiers operating into the

HF band. This Tesla coil runs at

300 kHz rather than the 60 Hz AC line current on the others. Author Harvey

Pollack claims it will light a fluorescent bulb from several feet away. A unique

feature is a "tunable" transformer that can be tweaked for maximum output

voltage by sliding the smaller primary coil up or down on the longer secondary

coil. Enameled copper magnet wire should be a suitable substitute for the

double-cotton-covered type called for in the article (Formvar, also mentioned,

is still available). Note: This 300 kHz oscillator likely violates the FCC's

limit on unintentional and/or intentional radiation in the band, so be aware.

The is primarily the aeronautical and maritime communications band.

See

Tesla's Trickery,

A Tesla Coil,

Big Tesla Coil.

A Tesla Coil

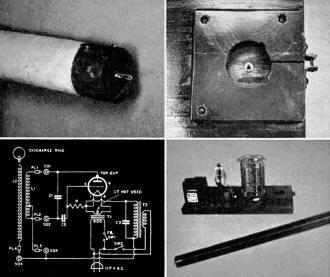

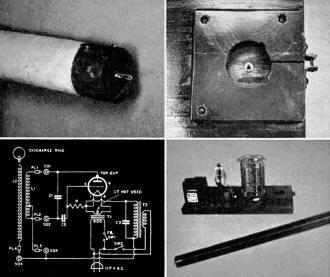

Vertical tube is secondary of Tesla coil. Wire ring on top discharges

high voltage and lights fluorescent bulb. Actually, bulb lights at several feet.

By Harvey Pollack

Demonstrate high voltage principles with this unit; corona discharge. ionizing

gas tubes and lightning.

Few electrical phenomena are as startling as the hissing blue corona discharge

from a Tesla coil. When bystanders see an unconnected fluorescent lamp held in your

hand light up brightly, their astonishment knows no bounds. These, and other tricks

such as a steel wool St. Elmo's fire and artificial lightning to a hand held screwdriver,

make this high-efficiency Tesla coil a fascinating and educational project.

Invented by Nikola Tesla about 1886, the device that bears his name is really

a transformer operating under rather special circumstances. Instead of using 60

cycle alternating current, the primary winding is supplied high-frequency AC (in

this model about 300,000 cycles per second) . The primary has relatively few turns

of heavy wire. Coaxial with the primary is a secondary coil containing many, many

turns of fine wire. Thus, to start with, the arrangement constitutes a step-up transformer

with a large secondary-to-primary turns ratio. But this in itself cannot produce

the startling effects mentioned earlier. For proper operation the secondary coil

must be so constructed that it will resonate with its own distributed capacitance

and the stray capacitance of the circuit at the primary frequency. When this happens,

the voltages developed across the secondary winding become truly phenomenal.

Among the features that make this Tesla coil construction unique are: (1) a sliding

primary coil makes up for winding errors by tuning the system to resonance without

the need for a secondary capacitor. When correctly positioned, the primary induces

enough voltage in the secondary to produce four-inch corona sparks. (2) once a Tesla

coil is built, there is always a transportation and storage problem due to the long

secondary coil. In this model, both the secondary and primary coils are demountable;

the secondary is actually a plug-in coil, while the primary leads are connected

to the oscillator circuit via color -coded banana plugs and jacks. So - take it

apart in seconds to transport it to the place it is to be demonstrated, or to store

it on an ordinary, shallow shelf.

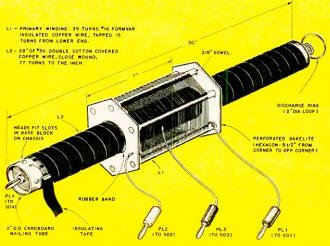

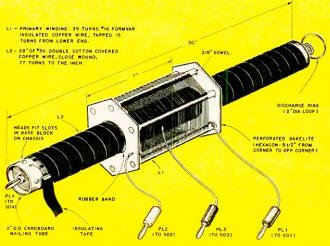

"Squirrel cage" primary is made of dowel sticks and hexagons

at each end. It is able to slide on secondary for tuning purposes.

Construction details for primary and secondary coils. Rubber

band on long secondary. just below cage, holds primary in place.

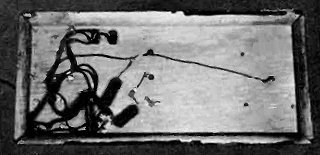

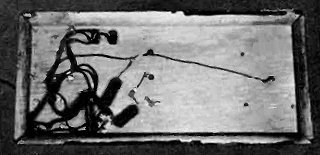

Underside view of wood chassis Is simple layout. Tape exposed

or unused leads.

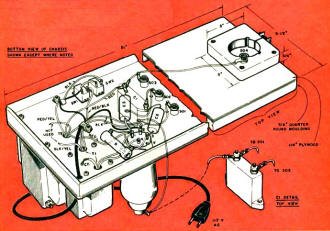

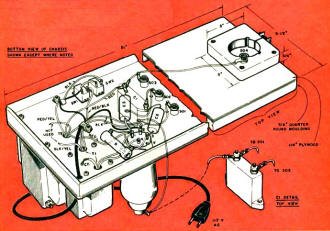

Left half of wiring guide shows underside of chassis. Right half

is a top view with detail of SO4. Note that Cl has been moved down for clarity.

Bottom of secondary has banana plug that inserts into socket

visible in photo at right. Retaining block for secondary, SO4 at center. Slot and

clamp at right adjust for tension.

The first step in construction is preparing the secondary coil.

A cardboard mailing tube 2 inches in outside diameter and 30 inches long is suitable

as a secondary coil form. (Bakelite tubing was used in the model because of its

greater rigidity, but cardboard is just as good.) Prepare the mailing tube by giving

it at least two coats of spar varnish, letting it dry 24 hours between coats. Obtain

a 2 lb. roll of #36 double-cotton covered copper wire and, starting 1 inch from

either end, start the secondary coil of close-wound turns. #36 d.c.c. wire gives

you 77 turns per inch and you have 28 inches to wind all told making a total of

2156 turns (a little over 1100 feet or 1/5 of a mile of wire) . There's no need

to count the turns; merely close-wind the full 28 inch stretch. Unless you use

a lathe for the purpose, you had better count on several sittings to complete the

winding. Keep a heavy rubber band handy to hold the final turns in place at the

end of each sitting.

When the winding is complete, apply several coats of shellac or varnish to hold

the turns firmly seated on the coil form. Cut two plugs of 1/2 or 3/4 inch stock

to fit in the ends of the coil form; drill each plug in its exact center, one hole

to take a standard banana plug and the other for a top binding post. Pass the ends

of the secondary winding through two fine holes at each extreme and solder the ends

to the banana plug and binding post, respectively. The secondary coil is now finished.

The primary coil can be started between varnish coats on the secondary. Cut 6

pieces of 3/8 inch wood dowels, each piece 7 inches long. Using a broad saw blade

or the edge of a file, cut 40 shallow notches in each dowel along its length. Start

the first notch 1 inch from one end, space the notches 1/8 inch apart so that 40

notches will occupy 5 inches all told.

Next, cut two hexagons of either 3 ply, 1/4 inch pine or fir, (5-1/2 inches from

corner to opposite corner) or using ordinary tin shears, cut the hexagons from thin

perforated Bakelite as was done in this model. Place the hexagons atop one another

and drill a 3/8 inch hole near each corner through each of the pieces. This will

assure accurate alignment of the pairs of holes. While in this position, cut a 2-1/8 inch diameter hole in each end plate to form the openings through which the

secondary will pass. Finally, slip the dowels into the pairs of holes in the end

plates flush with the surfaces and glue in place with a fast-drying cement. This

makes up the "squirrel cage" form for the primary coil.

The primary is wound by fitting #16 Formvar enameled wire into the dowel grooves

and pulling tight around each turn, for a total of 39 turns. The ends of the coil

may be wound once around the terminal dowel stick and crimped tightly in place.

Counting up from either end of the primary, scrape the Formvar or enamel insulation

clean from the 15th turn. After scraping both ends of the winding, solder 20 inch

lengths of flexible wire to each end and to the tap at the 15th turn. This wire

should have good insulation such as the vinyl material used on modern hookup wire.

Connect a colored, insulated banana plug to the free end of each of the wires; use

three different colors to match the banana jacks that will later be located on the

oscillator chassis. The primary coil is now finished.

To protect the thin insulation of the secondary turns, cover the entire winding

with one layer of a good grade of vinyl tape. This not only makes for long life

but also for trim appearance. After the coils are in place and the leads plugged

into their matching jacks, throw the filament switch on. The 811A tube filament

should light. Turn the filament off. Using a 12 inch wood ruler or any scrap wood

at least this long, place it under the bottom end plate of the primary and slide

the coil up on the secondary until its top end plate is about 1/3 of the way from

the upper end of the secondary. Turn on the filament for a least 10 seconds, then

turn on the high-voltage switch.

FROM THIS POINT ON, KEEP AWAY FROM THE COILS AND THE VACUUM TUBE. YOU ARE DEALING

WITH 1500 VOLTS FROM THE TRANSFORMER AND MUST EXERCISE EXTREME CARE TO AVOID SHOCK.

You may or may not get corona discharge from the wire ring in the upper binding

post at this time (see photographs) since the secondary may not be in resonance.

Let the primary slip slowly down the secondary column while you observe the ring.

At a well-defined point along the column, corona sparks should begin to shoot from

the ring. Note the position of the primary for maximum corona, TURN OFF THE PLATE

SWITCH THEN THE FILAMENT SWITCH, and then mark the correct position of the primary

coil with a bit of crayon on the vinyl tape. A heavy rubber band around this portion

of the secondary will serve to hold the primary in place during use.

The Tesla coil is used principally as a demonstration of high-tension electricity.

The corona discharge is fascinating to watch, especially in a dark room. Bring a

long fluorescent tube, held in your hand, about two feet from the secondary and

it will light brightly as if by magic; it will continue to glow up to four feet

from the coil.

Stand three feet from the coil with a neon lamp in your mouth. You'll look like

a human dynamo, because the lamp will glow brightly without connections.

Hold an insulated screwdriver in your hand and bring the blade within inches

of the discharge ring. Sparks will leap to metal, but you will feel nothing.

Lay a piece of medium steel wool about the size of a golf ball on the discharge

ring. When power is applied, you will see a startling display of St. Elmo's fire

coming from the many strands.

Make a five-pointed star of aluminum foil and connect it to the discharge ring

(vertically). Watch the streamers from the points and its spectacular effect.

If you can borrow some Geissler tubes filled with gases such as neon, helium,

argon, mercury vapor, etc., hold one end of each of these in your hand in a fan-like

arrangement. The display of colors will be startling, when they are brought near

the discharge ring.

Carefully remove the secondary and, while it is still coaxial with the primary,

lay the whole assembly on its side on a wood table top. Connect a length of wire

to the banana plug at one end and another length to the binding post and form a

6 or 7 inch spark gap. (Some retuning by shifting the primary winding may be necessary

since the secondary is now removed from ground.) REMEMBER THAT ADJUSTMENTS MUST

BE MADE WITH BOTH SWITCHES OFF!

|