Here is the "Electricity - Basic Navy Training Courses"

(NAVPERS 10622) in its entirety. It should provide one of the Internet's

best resources for people seeking a basic electricity course - complete with examples

worked out. See

copyright. See

Table of

Contents. • U.S. Government Printing Office; 1945 - 618779

Chapter 14

GENERATORS

ELECTRICAL PUMPS

Chapter 14 GENERATORS ELECTRICAL PUMPS The modern fighting ship consumes a tremendous

amount of electrical energy. The electrical machinery furnishes her men with food,

water, and fresh air. Her nerves are electrical wires coordinating all her activities,

all her power, to make her a fighting machine.

To get the electrical energy necessary to do her many jobs, the modern ship

operates huge generators. The dynamo room is the heart of her nerves and her muscles.

It provides the ears and the eyes for her guns, the muscles for her rudder, and

make her skipper's voice carry into every compartment. All this energy is derived

from oil by the simple process of A Wire CUTTING A FIELD OF FLUX-INDUCTION.

Generators - the engines of induction - are electrical pumps. They force electrical

energy through the ship - from her stem to her stern. Although generators are SIMPLE

IN PRINCIPLE - mutual induction machines - they are sometimes COMPLEX IN DESIGN.

When the design of a generator seems unnecessarily complicated, just remember that

it was built to do a job. And that job has certain requirements. If the only way

to meet the requirements is by complicating the machinery - then it's going to be

complicated. You don't handle a racing boat like you do a fishing tug.

HOW A GENERATOR IS BUILT

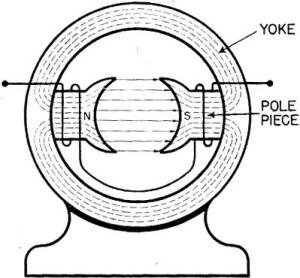

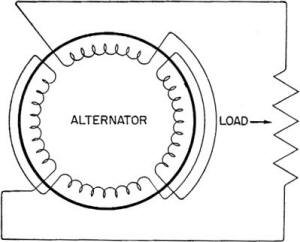

Since a generator is a mutual induction job, its first requirement is a magnetic

field. The simplest generator field is built like the drawing in figure 121. Two

electromagnets are mounted in a circular , iron frame called a YOKE. These electromagnets

are wound so as to produce opposite polarity. notice how the magnetic circuit is

entirely in iron except . at the center, between the poles. This area - between

the pole pieces - is the only part of the field outside the iron.

Figure 121. - Generator-magnetic field.

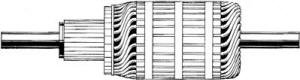

The yoke, its pole pieces, windings, and the field produced are the primary

circuit. The secondary circuit is a coil wound on an iron core. The coil and core,

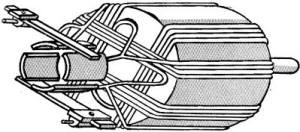

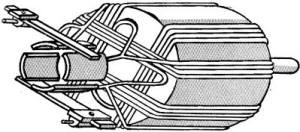

mounted on a shaft is the ARMATURE. Figure 122 shows a typical armature. To make

the generator complete, the armature of figure 122 fits into the area between the

pole pieces of figure 121.

HOW IT WORKS

The frame of the generator stands still - the field of flux is steady and stationary.

But; the armature shaft is rotated by a source, of mechanical power - the PRIME

MOVER. And as the armature is rotated, the conductors of the coil cut through the

field flux. As in the simplest, or the most complicated, system, conductors cutting

flux produce an induced voltage.

Figure 122. - Generator-armature.

These are the elements of a generator -

1. The field produced by electromagnets.

2. The prime mover feeding mechanical energy into the generator

by rotating

the armature.

3. The armature carrying a coil of wire through the field and producing

an induced EMF.

UNDERSTANDING the ACTION

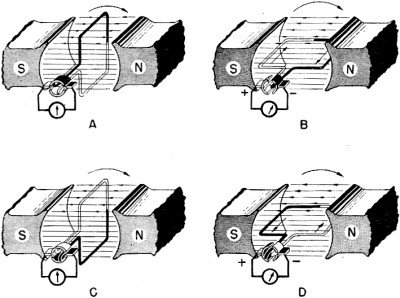

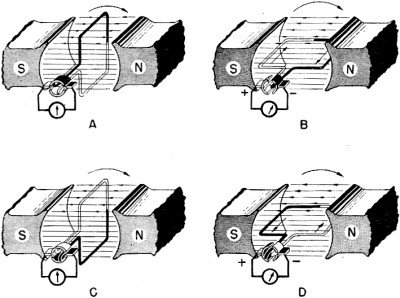

The easiest way to understand what happens in an armature, is to lift ONE TURN

of the coil off its iron core and study it alone. Figure 123 is a single turn rotating

in the magnetic field. The coil is shown in four positions which represent one complete

revolution of the coil. In A the coil is producing zero voltage - the galvanometer

reads zero. It's zero, because, in this position, the coil is cutting NO flux. How

can a coil move in a field and yet cut no flux? By moving parallel to the lines

of force. notice in A that both sides of the coil are moving in a straight line

between the poles. When conductors are moving this way they slip between the "rubbery"

lines of force and do not break them.

Figure 123. - Armature coil revolving in magnetic

field.

In B the coil has moved to a position at right angles with A. Now the black

side of the coil is cutting DoWNWARD and inducing a voltage OUT. And the white side

is cutting UPWARD and inducing a voltage IN. The galvanometer attached to the two

terminals of the coil deflects. Trace this circuit through. notice that although

the two induced voltages are opposite - one in and the other out - the voltage for

the TOTAL coil is the ADDITION of these two. Trace the current through the coil

- you go WITH both voltage arrows. This means that both voltages add force to the

current.

In C, the coil has turned one half of a complete revolution. C is like A except

upside down. Again, the coil sides are moving parallel to the lines of force. The

induced voltage is zero.

In D the coil position is the reverse of position B. The black side is now cutting

UPWARD and has an induced voltage IN. The white side is cutting DoWNWARD and has

an induced voltage OUT. notice that the current direction in the coil is the exact

reverse of position B. This is not amazing - you know that reversing the direction

of cutting reverses the direction of the induced voltage. Use your generator hand

rule - it will prove the arrows are correct.

The fifth position (if one were shown) would duplicate A. You have followed

a coil through one complete revolution. Two facts stand out. First, there are two

positions where the coil is moving parallel to the field-the induced voltage is

zero. These positions are called the NEUTRAL PLANE of the generator - in this two

pole job the neutral plane is midway between the poly pieces. Second, during one

half of the revolution, the coil's induced voltage is in one direction (counterclockwise).

During the other half of the revolution, the coil's induced voltage is in the opposite

direction (clockwise).

Half the time one way, and half the time, the other way? Sounds familiar. It

is - that's ALTERNATING current. A rotating coil always produces alternating current.

the COMMUTATOR

It's proved that rotating coils produce alternating current. But - go back to

figure 123 and check up on those galvanometer readings. How about it? In both Band

D the deflection is toward the right. This indicates that DIRECT current - is flowing

OUTSIDE the coil. How come - A.C. inside the coil and D.C. outside? The a.c. has

been RECTIFIED - that is, changed from alternating to direct current. The COMMUTATOR

did the job.

Examine the terminal ends of the coil in figure 123. Each end is connected to

a one half of a copper ring. These two halves of a copper ring, taken together are

the COMMUTATOR. Now notice how the commutator is connected to the outside circuit

(the galvanometer). On each half of the commutator (the halves are called SEGMENTS)

rides a block of carbon called a BRUSH. The brush and commutator connect the ROTATING

coil and the STATIONARY galvanometer. Without brushes and commutators, the leads

from a coil would be twisted off after only a few revolutions. That's one purpose

of a commutator-brush system - it provides a SLIPPING CONTACT between rotating armature

and stationary load.

But how does the commutator rectify the current? Let the brush where current

comes OUT of the coil be called NEGATIVE, and the brush where current goes IN the

coil be called POSITIVE. Now follow the coil through A, B, C, and D of figure 123.

The commutator segment attached to the side of the coil having current OUT is always

in contact with the NEGATIVE brush. And the segment attached to the side having

current IN is always in contact with the POSITIVE brush. Another way of, saying

the same thing - the rotating coil with its reversing current carries its segments

around with it. At the instant the coil goes through the neutral plane the current

reverses AND AT the SAME INSTANT the segments switch brush connections. This is

the other important purpose of the commutator - it rectifies the generated A.C.,

delivering D.C. to the external circuit.

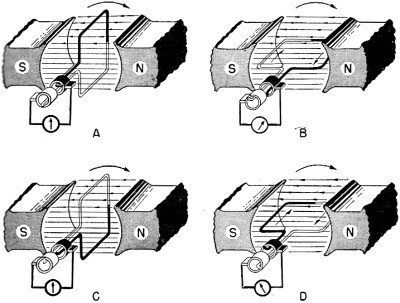

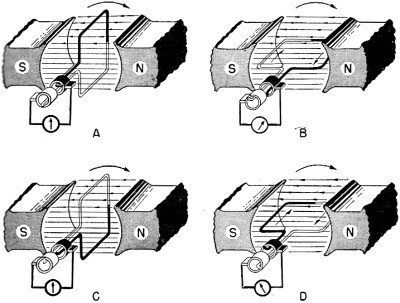

SLIP RINGS - A.C.

Instead of connecting a rotating coil to a commutator, connect each terminal

of the coil to a SLIP RING. Slip rings are simply smooth rings of good conductor

material. Now brushes riding on these slip rings will pick up a.c. and deliver it

to the external circuit. Figure 124 shows a rotating coil with slip rings attached.

Figure 124. - Slip ring coil revolving in magnetic

field.

Starting with A, the coil is in the neutral plane - no induced voltage. In B,

the coil is at right angles to the flux. The induced voltage in the BLACK side of

the coil is OUT. In the WHITE side, it is IN. SO you call the white ring POSITIVE

and the black ring NEGATIVE. In C, the coil is again in the neutral plane. In D,

the coil is once more cutting flux at right angles. But, now the induced voltage

in the BLACK side is IN. And in the WHITE side, it is OUT. Now, you call the white

ring NEGATIVE and the black ring POSITIVE. This means that through one half of the

revolution the white ring is positive and through the other half it is negative.

The same is true of the black ring. Consequently the current in the external circuit

reverses itself every time the coil current reverses. And the reverses occur every

time the coil passes through the neutral plane.

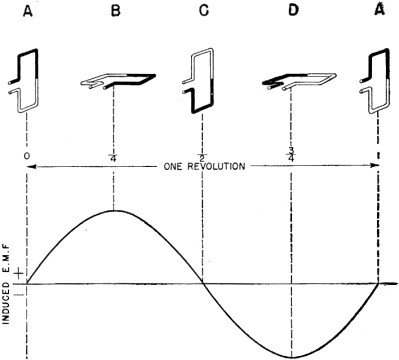

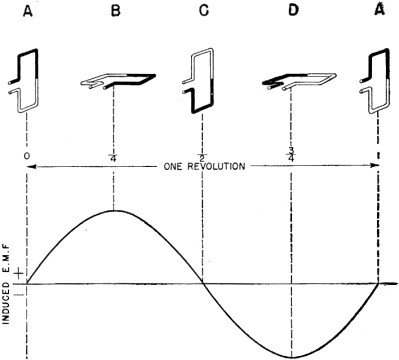

Figure 125.-Graph of alternating EMF.

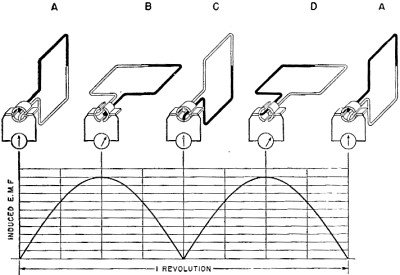

SUMMARY OF D.C. AND A.C.

All coils, rotating in a magnetic field, have a-c voltage induced. This a.c.

can be connected directly to an external circuit by means of slip rings. Or, it

can be rectified by means of a commutator in order to deliver d. c. to the external

circuit.

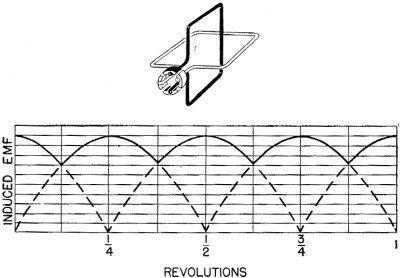

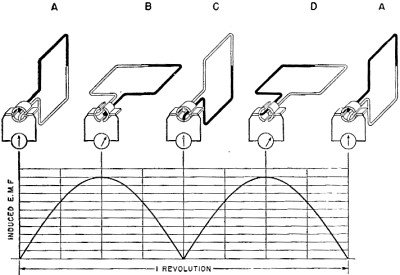

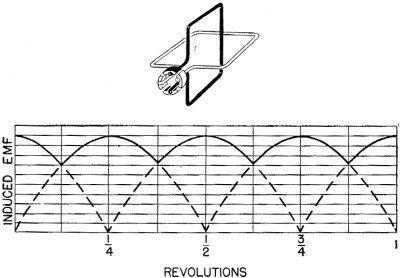

Figure 125 is a graph of a-c voltage. notice the small coils above the graph.

Each coil is in the proper position to produce the EMF indicated on the graph.

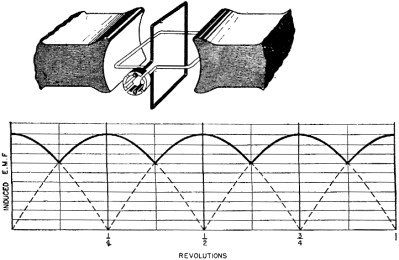

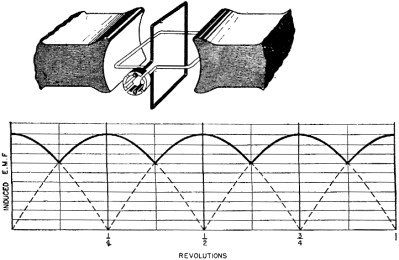

Figure 126 is a graph of d-c voltage. Again the small coil's position, corresponds

to the voltage indicated.

You are probably wondering what happens when the coils are somewhere in between

zero (neutral plane) positions and maximum (right angle) positions. The coil is

cutting flux all right, but not as many lines per second as at the maximum. Actually,

the conductors are cutting through the flux field at an angle. The closer this angle

comes to 90° with the flux, the more lines the conductor cuts. The closer this angle

comes to 0° with the flux, the fewer lines the conductor cuts. The result is that

the voltage builds up in a smooth upward sweep - from a zero value at the neutral

plane, to a maximum value at 90° from the neutral plane. The opposite is true when

the coil sides are going from a maximum point to a zero point. The voltage decreases

in a smooth downward sweep. The build-up and build-down is a SMOOTH process.

Figure 126.-Graph of direct EMF.

You should recognize the two graphs of figures 125 and 126 as typical graphs

of alternating current and pulsating direct current. Graphs of these two types of

current always have the general shapes of these figures.

MANY COILS

A single coil rotating in a magnetic field is like an 8-cylinder job hitting

on only one. The output power is weak and fluctuating. Fluctuation is a characteristic

of a.c. And adding more coils does not eliminate the regular rise and fall of a-c

voltage. But adding more coils to a d-c job smooths out the fluctuation and changes

the direct current from pulsating to regular d.c.

Figure 127.-Two coil armature.

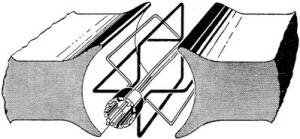

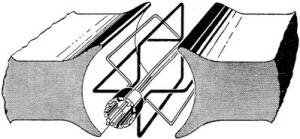

Here is how it works. In building up an armature from one to many coils, first

add one more coil at right angles to the first. Figure 127 shows the two coils arranged

on an armature at right angles to each other. When this armature is rotated, the

black coil is going to be one-quarter of a revolution behind the white coil. Which

means that the induced voltage of the black is at zero value when the white is at

maximum value. notice that a four segment commutator is required for the terminals

of the two coils. Brushes riding on this commutator contact ONLY the coil producing

the BEST voltage. Figure 128 is a graph of the volt-ages produced by both coils.

The heavy part of the graph is the voltage picked up by the brushes. This is the

voltage delivered to the external ciruit. notice that the voltage is more level

than it was with one coil. True, it still is a pulsating voltage - but now it doesn't

go all the way down to zero. Adding the extra coil has taken out some of the "bumps."

Figure 128. - Two coil voltage.

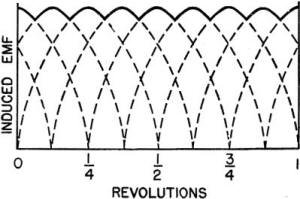

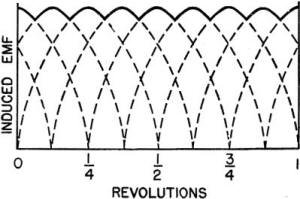

Add two more coils, placing them midway between the original coils on the armature.

Now you have a generator like figure 129. Figure 130 shows the voltage produced

- by this four coil job.

notE - it's now an eight segment commutator and the brushes are catching only

the very peaks of each coil voltage. Yes-it's still pulsating d.c. But a mild type

- the rise and fall is short.

From this four coil job to the simplest commercial generator is only a short

step. Figure 131 shows a GRAMME RING ARMATURE, one of the first practical armatures.

Figure 129. - Four coil armature.

Figure 130. - Four coil voltage.

The gramme ring armature does a whale of a lot that the one, two, or four coil

jobs did not do. FIRST - the coil is wound on iron. This reduces the reluctance

of the magnetic circuit by eliminating almost all the air gap. Consequently, a stronger

field and a higher induced voltage in the armature. SECOND - the windings are in

series - the individual voltages of the 'turns add together. Consequently, a higher

voltage at the terminals of the generator. THIRD - the coils form TWO paths between

the brushes - one path up either side of the ring. Therefore, this armature can

carry more current without overheating.

Figure 131. - Gramme ring armature.

Suppose you follow one ampere of current through this generator. Entering the

commutator at the positive brush, the current can only go into ONE segment because

all the segments are insulated from each other.

From the segments, the current goes out to the winding on the ring via the ARMATURE

LEAD marked A. At the winding, the current splits - half going up the right side

and half going up the left side. And why does current go UP these windings? Use

your generator hand rule - it will tell you that as the current goes through each

successive turn of wire, the induced voltage gives it a "kick" upward.

The first set of turns give it a kick of 20 volts. The second and third sets each

provide a kick of 40 volts. And the fourth set, like the first, provides 20 volts.

Adding these induced voltages - they're in series-the current has a total potential

of 120 volts. The currents from each side of the ring meet at lead B - both backed

by 120 volts 9f potential. The lead provides a path to the commutator segment for

both currents. The brush picks up the current from the segment and delivers it via

a BRUSH LEAD to the load. At the load the current loses its voltage - yes, all the

120 volts - doing the work of the load. Then, at zero voltage, the current reenters

the armature and gets kicked again by induced voltage until it has a potential of

120 volts - it's again ready for another circuit through the load doing the load's

work.

Now, how come the second and third sets of turns provided 40 volts, whereas,

the first and fourth sets only furnished 20 volts? It's simple - the second and

third sets are moving almost at right angles to the flux. They're cutting lines

of force at a high rate. The first and fourth sets are cutting at a wide angle and

consequently only break about half as many lines as the second and third sets. The

Gramme ring armature was designed to do this job - provide a HIGH voltage and a

STEADY voltage. It does both by means of series connections. notice that, as the

armature is turning, one set of turns after the other moves into the flux field

to provide a high and steady voltage.

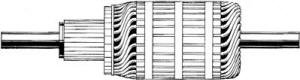

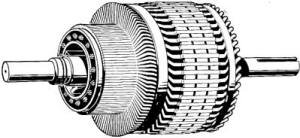

The modern armature, makes use of the DRUM WINDING, shown in figure 132.

Figure 132. - Drum wound armature.

Again, series connections and many coils. The principal advantages of the drum

winding lie in (1) the saving of wire, (2) the reduction of reluctance, (3) the

ease of repair. In the Gramme ring, half of the windings do not cut flux. They're

on the INSIDE SURFACE of the iron ring, while the flux is traveling WITHIN the ring.

In the drum armature, all the windings are placed on the OUTSIDE SURFACE of the

iron core. The flux is cut by EVERY conductor as the lines jump from the iron pole

piece to the iron core of the armature. The drum armature core is iron all the way

through as contrasted to the air center of the Gramme ring. Air increases reluctance

- therefore, the drum armature has less reluctance. It's hard to repair a ring armature-damaged

sets of turns must be replaced by hand and spliced to the undamaged portion of the

winding. In the drum winding, any damaged coil can be lifted individually, repaired,

replaced, and re-connected by soldering to the proper segments of the commutator.

Figure 133. - Modern drum wound armature.

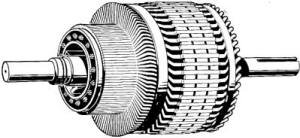

Figure 133 shows a modern drum wound armature. notice the great number of coils

and commutator segments to give this job a high and steady voltage.

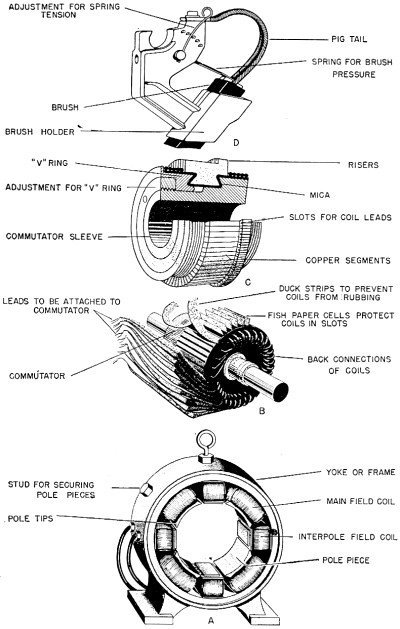

CALLING IT BY NAME

"That thing," "jigger," "it," "thing-a-ma-bob,"

and "gadget," may be okay on the beach. But in your Navy you're supposed

to know what you are talking about. In fact, you've got to be able to make OTHERS

know what YOU'RE talking about. The parts of generators have accurate names - USE

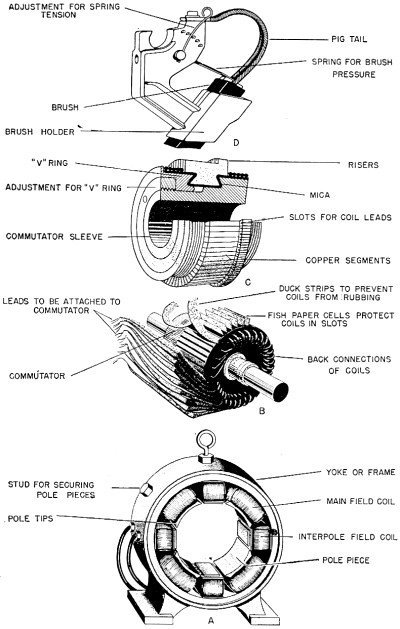

THEM. Figure 134 shows the four main parts of a generator-the FRAME, the ARMATURE,

the COMMUTATOR, and the BRUSH RIGGING. Each part is labeled with its correct name.

LEARN "EM"! You'll sound a lot more savvy on your job.

ALTERNATORS - A-C GENERATORS

It would be simple if alternators followed the generator pattern in their

development-one -coil, two coils, many coils .. It would be nice and simple -BUT

they just aren't built that way! Alternators have a special design that's MECHANICALLY

OPPOSITE to the generator. Alternators ROTATE the FIELD and hold the ARMATURE STATIONARY.

It's perfectly true that alternators COULD be built by increasing the number

of turns of the coil and taking the a.c. off through slip rings. A coil of many

turns would step up the voltage to a usable value. And a very few alternators are

built this way. They work just like the d-c generator except that the commutator

is replaced by a set of slip rings.

Generally speaking, the alternator is designed to produce a much higher voltage

than the d-c generator. In a.c., transformers can reduce this high generated voltage

to a safe value for use. This is impossible in d.c. - transformers do not work on

d.c.

Figure 134. - Parts of a generator.

Generating high voltages (as high as 25,000 volts) makes the use of slip rings

impossible. Any voltage above 1,000 volts cannot be handled on slipping contacts

- either commutator or slip rings - because of arcing. Even as much as 700 or 800

volts arcs dangerously. These arcs are like miniature bolts of lightning - jumping

from brush to slip ring. Each arc digs a pit into the slip ring, soon wearing it

out. When the voltage is in the thousands, arcs may jump from ring to ring, brush

to brush, or brush to frame. It's obvious, then, that slip rings cannot be used

to take high voltage a.c. off an alternator.

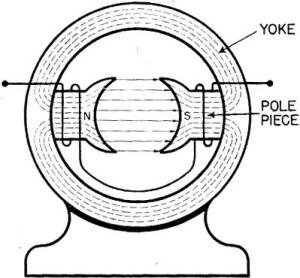

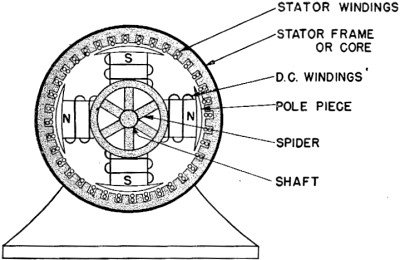

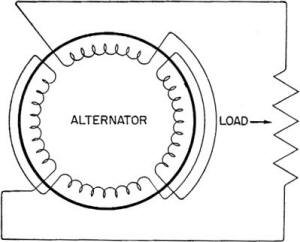

ALTERNATORS-ROTOR AND STATOR

To eliminate the dangers of arcing - and still generate high voltages - conductors

are held stationary and the flux field is moved across them. The alternator does

just that. The field poles are mounted on a shaft and rotated. This is the ROTOR

of an alternator. The energizing current for the field poles - d.c. - must be fed

into the rotor by slip rings. This energizing d.c. is at a low voltage, usually

110 or 220 volts, so it is safe to use slip rings. The armature is wound as a many-turn

coil inside a slotted frame. This frame is stationary - it is called the STATOR

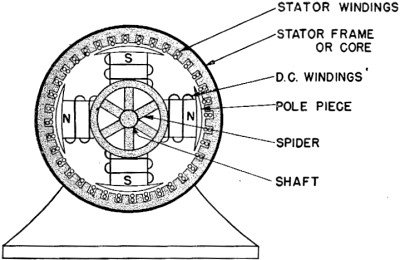

of an alternator. Figure 135 is a cross section of a four pole alternator.

Figure 135. - Four pole alternator.

It works this way - the rotor with its magnetic, field sweeps across the stator

windings. As the lines of force are cut by the stator windings, a voltage is induced.

Imagine the rotor of figure 135 turning. First the N pole flux cuts the left side

of the stator. After one quarter of a revolution, the situation is reversed. The

S pole flux cuts the left side, and the flux has reversed for all windings on the

stator. The effect is that of reversing field direction. And, when field direction

is reversed, so is the direction of induced EMF. Alternating current is the product.

Figure 136. - Schematic of stator and load.

The alternator builds up a strong voltage by having many turns on both rotor

and stator. The multi-turn rotor produces a strong flux (NI). And the multi-turn

stator is connected in series so that voltage adds. The combination of MANY conductors

cutting a STRONG field generates high voltages. If you trace current through an

alternator as you did through a Gramme ring, you will find the principles the same.

Follow the current through figure 136. current enters the positive lead of the stator

and travels through the windings. It picks UP the induced voltage, and leaves on

the negative stator lead. Then it goes through the load, where it loses its voltage

doing work, and returns to the stator to repeat the process. The fact that a.c.

reverses direction periodically does not alter this process. Regardless of whether

the current is positive or negative, it picks up voltage in the alternator and spends

voltages in the load.

MORE ON DESIGN

Different electrical loads require the employment of generators of varying design.

An a-c load requires an alternator - a d-c load requires a generator. More specific

requirements are met by utilizing various connection patterns within the generator.

These more complex jobs are too advanced for this basic book. You have the PRINCIPLES

-you'll get the details in the book for YOUR rating.

Chapter 14 Quiz

(click here)

|