|

March 1957 Radio & Television News

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Radio & Television News, published 1919-1959. All copyrights hereby

acknowledged.

|

Anyone who has dealt with older

electronics equipment knows that one of the first kinds of components to go bad

is the electrolytic capacitor. Materials used at the time degraded fairly rapidly,

especially compared to modern materials, which facilitated leakage of stored charge

between the rolled up layers of conductive plates and interstitial insulating paper

(or other material) layers. As outlined in this 1957 article from Radio &

Television News magazine, symptoms of electrolytic capacitor malfunction in radio

and television are most often some form of audible noise, light or dark lines within

the picture scan, or outright power supply failure. Since electrolytics are typically

large valued capacitors, they are used in power supply circuits for filtering the

line 50 or 60 Hz (depending on your country) AC frequency (and their harmonics)

and for interstage AC coupling. This article presents a simple method for testing

leakage levels in electrolytic capacitors to determine whether they should be replaced.

Many restorers of old electronic equipment routinely replace all the original electrolytic

capacitors because it is almost certain that leakage will either immediately or

in short order cause problems.

Are Your Electrolytics Leaky?

By Ben Crisses and David Gnesin By Ben Crisses and David Gnesin

It is not unusual for a service technician to accumulate quantities of electrolytic

capacitors of questionable quality. The collection occurs in this way: In routine

servicing, he may decide that the quickest way to check electrolytics is to bridge

a doubtful unit with a new one.

Even when results are indefinite, technicians will often wire the new unit in

as a permanent replacement, as the proverbial "ounce of prevention." The old unit

is laid aside without further examination, for time is important and customers are

impatient. When business slows down, why not dig out these removed units and give

them a qualitative check? It's easy.

Since excessive leakage is the characteristic that impairs the efficiency of

electrolytics, a measure of leakage current is the best test. If this leakage current

is within the tolerance recommended by the manufacturer, the capacitor may be considered

good. In fact, the production test and the tolerances generally used may be duplicated

in the shop without much difficulty. A multimeter, a voltmeter, and a d.c. source

(an old receiver will do for the latter) are the principal ingredients. In addition

a 1-megohm potentiometer, a 10,000-ohm potentiometer, and a single-pole, single-throw

switch are used. A fuse may also be added, as shown.

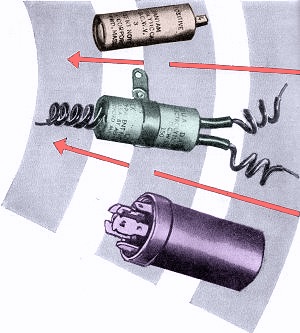

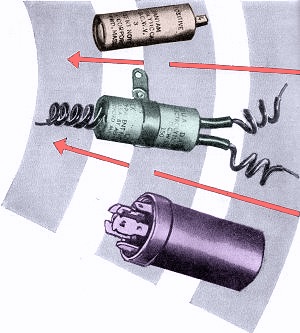

Fig. 1 - Leakage current through capacitor is measured at

rated voltage with the simple test circuit depicted here.

Fig. 2 - Leakage for a given combination of capacitance

and voltage rating should not exceed values shown here.

Fig. 1 shows the manner in which the meters, pots, switch, and d.c. source

are connected, as well as the capacitor under test. Be sure, in this arrangement,

that the capacitor is connected in the proper polarity, with its positive terminal

going to the positive side of the voltage source.

Begin the test with the switch open, by adjusting R1 so that the voltage

being supplied for test purposes and being monitored by the voltmeter, is equal

to the voltage rating of the capacitor. Then adjust R2 to the position

of maximum resistance; that is, so that its full 10,000 ohms is in series with the

capacitor and the milliammeter. Now the switch is closed and resistor R2

is moved toward its position of minimum resistance. This must be done slowly to

avoid injury to the meter.

Observe the reading on the milliammeter while rotating R2, comparing

it with the graph of readings in Fig. 2. If the meter reading does not exceed

the recommended maximum shown in this graph, the capacitor is within tolerance and

has useful life ahead of it.

An example will serve to illustrate:

Suppose you have a 40-μfd. electrolytic rated at 450 volts. Hooking it up

as shown in Fig. 1, R1 is set to supply 450 volts. After R2

is set to be fully in the circuit, S1, is closed. Now slowly begin reducing

the resistance of R2 while observing the meter. If R2 can

be completely shorted out without leakage current exceeding 19 milliamperes, the

capacitor is still useful.

An easily set up quality test for the many unused filter capacitors gathering

dust in most shops.

The ethics of impressing a used component into service as a replacement for a

customer is something else again. There is no intention of encouraging the use of

such parts instead of new ones. However, there are countless other applications

around the shop where electrolytics in good condition, although they have already

seen service, come in handy.

One precaution should be observed: if, while decreasing R2, the milliammeter

reading should begin to rise above 35 milliamperes, open S1 quickly.

Leakage of this order indicates an extremely leaky capacitor, which could short

out and damage the circuit.

Posted June 15, 2022

(updated from original post on

1/22/2014)

|

By Ben Crisses and David Gnesin

By Ben Crisses and David Gnesin