|

Most people today under 30

years old have probably never seen the mechanics or electronics inside their many

personal devices. Everything is so miniaturized and optimized that if something

does go wrong, there is little chance of the owner repairing it. Instead, the phone,

television, stereo, microwave oven, whatever, gets thrown away and a relatively

cheap (compared to paying for a repair) replacement is purchased (or stolen). Besides,

if the item was more than two years old, it was on the verge of obsolescence anyway.

Up until around the early to mid 1980s you had a fair chance of being able to

repair an electronic circuit if trouble arose because at least with commercial products

printed circuit boards (PCBs) were usually 1- or 2-sided and the components still

had leads protruding from the sides of the packages. A $10 Radio Shack soldering

iron and some solder wick was sufficient to remove and replace just about any failed

component. Home brew PCBs could be made to nearly the same quality as commercial

versions using a resist ink pen (basically a Magic Marker) and a dish of ferric

chloride etchant liquid. A drill press helped with making holes for the component

leads, but a hand drill would get the job done. No more, though. If you are resourceful

enough to get your cellphone or camera open without destroying it, you will find

a very neatly laid out, extremely high density PCB with parts so small you might

wonder how they could work at all. Forget servicing the thing with a soldering iron

and a pair of pliers - you will need at least a hot air wand, a magnifier, tweezers,

and, of course, electrostatic discharge (ESD) preventative gear.

In 1949 when this article appeared in Radio & Television News, printed

circuits were just coming onto the scene. Bakelite, steatite, and ceramic substrates

were typically used at the time. Some processes were already using printed resistors

and small-value inductors via silk-screening techniques.

Part 2. A discussion of the techniques and equipment used in making printed circuits

for home-built units (January

1950). Thanks to Terry W. for providing this article.

Printed Circuits - Part I

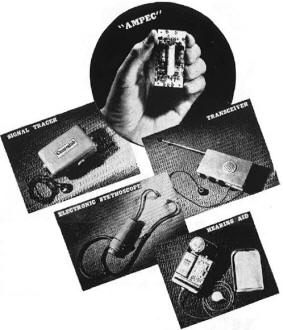

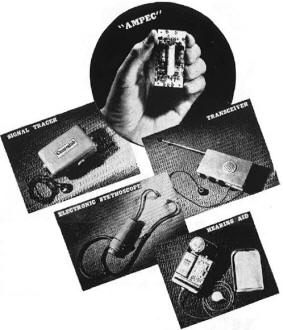

This typical group, only a few of the many commercially built

units already produced, is an example of how Centralab's printed circuit audio amplifier

has been received by the industry.

By John T. Frye

A review of printed circuit techniques. To be concluded next month with on article

on how the experimenter can apply, in a simplified form, printed circuits to home

constructed units.

A very loud bang announced to the electronic world early in 1945 that printed

circuits had moved from the experimental to the practical stage, for it was at that

time that the National Bureau of Standards, working closely with the Centralab-Division

of the Globe Union Company, began mass production on the tiny radio proximity fuse

for mortar shells: a fuse incorporating a complex electronic circuit "printed" on

a thin steatite plate 1 3/4" long by 1 1/4" wide!

Since that time, the printed circuit has thrust its tentacles into every portion

of the electronic field; and it has miraculously shrunk everything it touched. Hearing

aid amplifiers, complete with batteries, that are smaller than a cigarette package;

personal radios that can be cradled in the palm of the hand; radio and television

subassemblies occupying only one-tenth the space needed for conventional assemblies

and requiring one-half as many soldered connections for installation: these are

but a few of the achievements of this new process, and the surface has barely been

scratched. Every day sees new applications of this method by which space is saved,

weight is reduced, assembly is simplified, and cost is cut.

Every electronic worker is certain to come in contact with printed circuits in

increasing number, and it is the purpose of this article to prepare him for that

contact by making him familiar with the various methods and techniques by which

these circuits are produced commercially and then showing him how he can develop

and experiment with his own printed circuits.

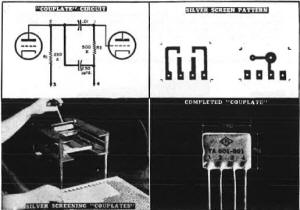

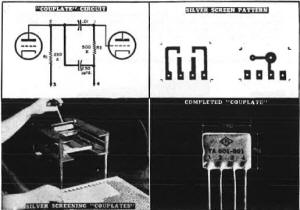

Fig. 1 - The "Couplate" unit. It contains a complete interstage

coupling circuit.

First, it should be clearly understood that the term "printed circuit" covers

any reproduction of an electrical circuit upon an insulating surface by any process.

Essentially it changes a bulky three-dimensional array of electrical parts and conductors

into a compact and very nearly two-dimensional arrangement. An example best shows

how this is done:

Suppose we want to build the complete interstage coupling circuit shown in Fig.

2. First, let us redraw our diagram on a tiny plate of steatite approximately 1"

x 3/4". If. Then let us carefully trace out the heavy lines with a small brush which

we have dipped into a "paint" made by mixing fine particles of silver together with

a liquid binder to hold the particles together and a solvent used to make the mixture

thin enough to brush.

Next, suppose we have several different solutions of finely powdered graphite

or lamp-black, a resin binder, and a solvent. We can experiment with these until

we find just the right combination of mixture, thickness, and length of line needed

to produce resistances equal to R1 and R2; and then we carefully

paint in these resistance lines at the proper points between the silver conducting

lines already drawn. Then we place our little plate in an oven and raise the temperature

to the point where our lines of paint will be "fired" directly to the ceramic base,

adhering to it with a tensile strength of 3000 pounds to the square inch.

Finally we solder tiny ceramic condensers of the proper values across the gaps

representing the condensers, and then we attach flexible leads to our silver paint

at points 1, 2, 3, and 4. The result is a "printed circuit" that will perform exactly

the same as one using conventional components, but our printed sub-assembly will

be no bigger than a postage stamp and require only four soldered connections to

be made by the radio assembly-line operator. A commercial version of just such a

printed circuit is shown in Fig. 1.

Fig. 2 - Diagram of "Couplate." Finished unit measures 1-1/16

x 13/16 x 3/16 in.

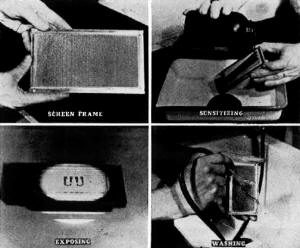

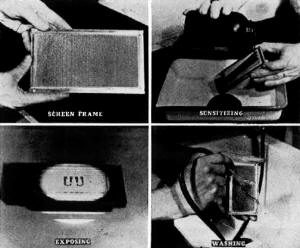

Fig. 3 - These individual operations show the method used

in preparing a silk screen.

Fig. 4 - Silk-screen printing. Paint is forced through the

open mesh of the screen. After the screen is removed. the surface of the base plate

is found to be printed with an exact, sharp-edged, uniformly thick design of the

required conductor circuit. A second stencil can then be used to print the resistors

in their proper location.

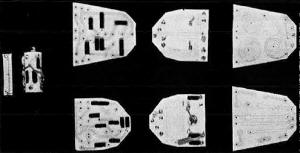

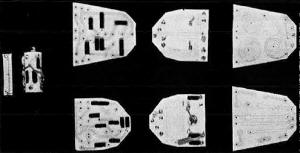

Fig. 5 - Front and rear views of one of the many hearing-aid

amplifiers that are printed on ceramic plates.

Fig. 6 - A high temperature oven is used for firing a group

of printed circuits. (Note lack of hand and eye protection)

Fig. 7 - Partially completed electronic circuits printed

on steatite plates and cylinders by the silk-screen process. Light lines are silver

conductors and inductors; dark rectangles are resistors; circular disks are ceramic

condensers.

Fig. 8 - Illustrating the evolution of an audio plate-to-grid

coupling circuit.

Such a manual process, while pointing up the difference between printed and conventional

circuits, obviously could not be adapted to mass production. Various stenciling

methods are the answer to producing more uniform circuits at higher speed, and the

silkscreen process is one of the most successful.

In this system, a fine-meshed silk screen is tightly stretched on a wooden frame

and covered with a photosensitive material that becomes insoluble when exposed to

strong ultraviolet light. A photographic-positive mask of the exact shape of the

required conducting circuit is placed on top of the screen, which is then exposed

to the rays from an ultraviolet lamp. Finally, the portions of the film protected

by the mask are washed away in cold water, leaving a stencil of the conductor design

to be printed. All four of these steps are clearly illustrated in Fig. 3.

This finished stencil is held securely against the base plate to be printed;

and the circuits can be printed on practically any insulating material, or even

on conducting material that has been coated with a non-conducting film, such as

lacquer, and a quantity of silver paint is placed at one end of the screen. A neoprene

bar, or "squeegee," is moved across the top surface, forcing the paint ahead of

it and down through the open mesh of the design, as is shown in Fig. 4. When

the screen is removed, the surface of the plate is found to be printed with an exact,

sharp-edged, uniformly-thick design of the required conductor circuit. A second

stencil can be used to print the resistors in their proper places. The paint is

fired to the base exactly as was done before. This process is shown in Fig. 6.

In Fig. 7 are displayed base plates at various stages of completion.

Brushing and stenciling with a silk screen are not the only ways in which the

conducting and resistor paints are applied. For example, a decalcomania, .on which

the circuit is printed on a thin flexible film that can be transferred to the final

surface, is useful in applying the circuits to cylindrical or irregularly-shaped

objects. The film is removed by firing.

Most standard printing processes are also used. As a single example, the required

design can be raised on the face of a rubber stamp, and this stamp can be pressed

first on a pad of conducting ink and then on the surface to be printed. Plating

of this printed design will increase its conductance if necessary. In the same way,

other printing processes such as engraving, lithographing, and intaglio are also

employed.

You old-timers who used to draw your own grid-leaks with a lead pencil were using

a form of printed circuits that still may have possibilities. Pencils having "leads"

of varying degrees of conductivity, or pens filled with conducting inks are being

used experimentally. With such devices an experimental circuit could be drawn and

constructed ready for testing all at one and the same operation!

Condensers can be painted, too, by employing silver disks painted on opposite

sides of the base plate so that the plate material becomes the dielectric. If the

plate is constructed of high-dielectric material, condensers of reasonable capacity

can be obtained by this method; otherwise, miniature thin-disk ceramic condensers

are often employed by soldering them with a low temperature solder directly to a

silvered area on the base.

Printed inductors are also used, especially in the low-inductance values. Spiral

forms are used on flat bases, although the more conventional forms can be used when

the circuit is printed on the tube envelope or a cylindrical base plate as is shown

in Fig. 9. The inductance of a spiral conductor can be increased by covering

it with an insulating layer of lacquer and then painting another spiral right on

top of it and connecting the two in series, painting another spiral on top of that,

etc. The distributed capacity and the Q of the circuit required are the limiting

factors to the usefulness of this method.

Placing a layer of magnetic paint, made of a colloidal suspension of powdered

magnetic material, both beneath and above the spiral conductor, with insulating

layers serving to protect the turns of the inductance from shorting. will also increase

the inductance.

The spraying of conducting films on insulated surfaces is another method of printing

circuits. The same paints can be used in paint spray guns as for the stenciled-screen

process; or molten streams of metal can be sprayed through locating stencils. Guns

are available in which the metal to be sprayed is fed into the gun in the form of

a wire, where it is heated to the melting point by a hydrogen-acetylene or other

flame. Compressed air is used to atomize the molten metal and to drive it on to

the work. This molten material can .be sprayed on wood, Bakelite, plastic, and even

ceramic surfaces.

One popular method employs a plastic base plate. This plate is sandblasted through

a mask so that shallow grooves are cut where the conductors are needed. These grooves

are sprayed full of molten metal, after which the surface can be milled, leaving

conducting lines that are flush with the surface of the plastic base plate.

Still another scheme uses an insulated base plate with a thin evaporated coating

of conducting metal. This is covered with a photosensitive film and exposed to light

through a mask. The film is developed so that the portions exposed to light are

removed, and the remaining portions, outlining the desired circuit, resist an abrasive

spray so that the protected portions beneath remain intact while the rest of the

metallic coating is cut away by the sand blast.

Another method of producing "printed circuits" is by chemical deposition. This

method is not used much on a commercial basis because of the very thin layers deposited

and other technical difficulties, but it consists essentially of depositing a thin

silver coating on a masked surface by the same chemical methods that are used in

silvering mirrors. Increased conductivity can be secured by repeated silvering or

by plating.

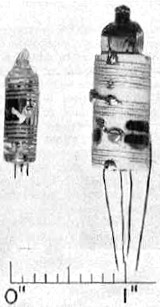

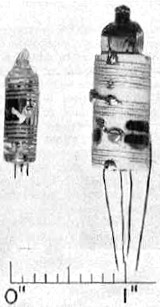

Fig. 9 - Two complete high-frequency transmitters ready

to be connected to a power supply. The one printed on the glass envelope of the

6J4 tube operates on 136 mc.; that printed on the ceramic cylinder surrounding the

subminiature triode operates on a frequency of 116 mc. Both transmitters are intended

for grid modulation.

Cathode sputtering and evaporation are two other processes for depositing the

metallic film. In the former, the material to be deposited is used as a cathode

and the masked base plate is used as the plate of a temporary vacuum tube. The "plate"

is maintained at a high positive potential with respect to the cathode, and the

latter is raised to a volatizing temperature. The metal particles emitted by the

cathode are attracted to and deposited on the base plate through the stencil openings.

The evaporation process is the same except that the plate is not maintained at

a high positive potential. The cathode material is simply heated in the vacuum until

it vaporizes on to the work. This permits the use of non-metallic as well as metallic

base plates. In neither case is the film deposited thick enough to be used for conductors,

but this can be overcome by plating.

The radio technician is very familiar with one form of printed circuit: the die-stamped

loop antenna. This is produced by placing a thin sheet of copper on top of a composition

or Bakelite panel with a layer of thermoplastic cement between. This sandwich is

placed in a punch press, and at one stroke the metal is cut into a helix and is

bonded to the panel.

Dusting is the final major method of printing circuits. This consists of depositing

a layer of metallic dust on a base plate along the lines where conductors or resistors

are required and then raising the temperature sufficiently to drive off the bonding

material and to fuse the metal particles together and to the plate. The entire plate

can be covered with an adhesive material and the dust applied through a stencil,

or the adhesive material can be applied through the stencil and then the whole plate

subjected to dusting, with the same results.

While an attempt has been made to touch on all of the methods ordinarily used

for printing circuits, the new industry is advancing so rapidly that one cannot

be sure how long this will hold true. Very recently, for example, the Glass Products

Company of Chicago announced a new process, "Micro-screening," which they claim

has several advantages over the silk-screen methods. Unfortunately, because of current

patent proceedings, details of this new method are not available.

Several illustrations are given to show the wide variety of devices to which

printed circuits are applied. For a more detailed discussion of the various methods

discussed in this article, the author recommends the purchase, for 25c, of "Printed

Circuit Techniques," by Cledo Brunetti and Roger W. Curtis. This National Bureau

of Standards Circular 468 can be obtained from the Superintendent of Documents,

U. S. Government Printing Office, Washington. D. C. An excellent group of references

for further reading will be found in the back of this booklet.

Part 2 of this article will be concerned solely with explaining and illustrating

how the experimenter can design and construct his own printed circuits with materials

easily obtainable. (To be continued)

|