February 1958 Radio-Electronics

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

If you happen to be Estonian,

you might think of something entirely different than most RF Cafe visitors do when

we hear the word "getter." In fact, you probably capitalize the word since it is

the name of a pop singer from your country,

Getter Jaani. If you are

a child living in Japan, you would probably think of

Getter Robo, an anime from a popular cartoon series. I suspect just about

everyone who visits RF Cafe knows getter as the silvery deposit If you happen to be Estonian,

you might think of something entirely different than most RF Cafe visitors do when

we hear the word "getter." In fact, you probably capitalize the word since it is

the name of a pop singer from your country,

Getter Jaani. If you are

a child living in Japan, you would probably think of

Getter Robo, an anime from a popular cartoon series. I suspect just about

everyone who visits RF Cafe knows getter as the silvery deposit

(typically barium) that resides inside vacuum

tubes for the purpose of helping to maintain the vacuum and to absorb pesky random

molecules that might otherwise cause electrical noise

in the circuit. This article from a 1958 edition of Radio-Electronics magazine

discusses the purpose of getter. BTW, I had never heard of either of the other two

Getters due to OGS (old guy syndrome). (typically barium) that resides inside vacuum

tubes for the purpose of helping to maintain the vacuum and to absorb pesky random

molecules that might otherwise cause electrical noise

in the circuit. This article from a 1958 edition of Radio-Electronics magazine

discusses the purpose of getter. BTW, I had never heard of either of the other two

Getters due to OGS (old guy syndrome).

Notes on the Getter

|

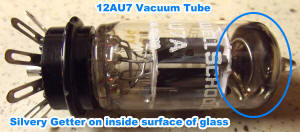

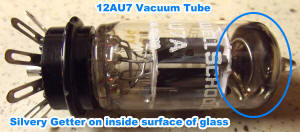

Getter inside 12AU7 vacuum tube. (RF Cafe

photo)

|

By Norman V. Becker

In high-gain audio circuits, tube noises such as hiss and frying are some of

the most troublesome things encountered. They can be eliminated only by selecting

tubes which are inherently quieter or by reducing stage gain with negative feedback.

In the latter instance gain might have to be reduced by such a factor as to defeat

the original purpose.

Hiss is created by DC resistance paths existing between various elements inside

the tube. These leakage paths may be as high as 1,000 megohms and would not upset

normal tube operation if they remained constant. But like a bad carbon resistor,

they create noises of their own through random and erratic changes of resistance.

Leakage paths of this sort are primarily located on the top mica support wafer,

where the support rods are punched through. If the wafer is contaminated by impurities,

it becomes a highly unstable conductor, connecting tube elements through very-high-resistance

paths. Unfortunately, contamination of the wafer during tube manufacture is almost

unavoidable. Before sealing the tube envelope, as much air as possible is exhausted

by vacuum pumps, but a small percentage of oxygen and other gasses remain inside.

This is where the getter comes into the picture. A small square loop of wire

usually located at the top of the tube, part of it coated with an explosive substance

similar to that used in photoflash bulbs. High-frequency radio waves penetrate the

sealed envelope and heat the getter to a temperature high enough to fire this coating.

This miniature explosion burns up the remaining atmospheric gasses inside the tube

and, at the same time, splatters a mirror-like silver coating over a portion of

the inner surface (a familiar sight in glass tubes). Some of this splatter falls

on the mica wafer, making it slightly conductive.

To reduce contamination of this sort, certain premium tubes are manufactured

in which the space between getter and wafer is materially increased. In other types

two top wafers are used - the upper one insulated from the lower - and act as an

umbrella to receive most of the splatter. Another method is to punch oblong slots

in the wafer. These openings effectively lengthen DC leakage paths and thereby reduce

noise.

In designing high-gain input stages for microphones and low-output pick-ups,

it is desirable to use premium tubes whenever possible. Special manuals describing

these types are published by tube manufacturers, giving electrical data, physical

dimensions, recommended applications, etc. In many instances premium tubes are directly

interchangeable with standard types which you might now be using. In addition to

reducing hiss, premium tubes are less microphonic, have lower hum and are generally

more dependable - and are more expensive.

|