|

August 1933 Radio-Craft

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Craft,

published 1929 - 1953. All copyrights are hereby acknowledged.

|

This 1933 Radio-Craft

magazine article is typical of the much-hyped (at the time) all-metal

vacuum tubes in the mid 1930s. Their British proponents predicted glass-encased tubes

would quickly become obsolete once everyone realized how the added expense of

metal encasement would easily be offset by the many advantages offered by metal

tubes. Like so many grand new innovations with fantastic promises, this one never

quite panned out. Metal tubes have/had their place in certain applications, but

turned out not to be the panacea hoped for. Undeniably, superior noise immunity

and greater ruggedness and thus reliability are features difficult to replicate

in glass tubes, but not all tubes needed such perfection. If you are interested

in the history of metal tubes, then check out this article which was later referenced

in an

October 1935

piece where it says, "Several years ago, an English company started to manufacture

wholly metallic tubes in which practically no glass was used except in connection

with certain parts of the sealing (Radio-Craft, August 1933)."

A New English All-Metal Tube

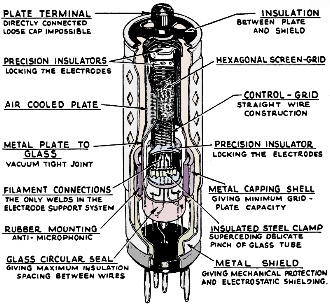

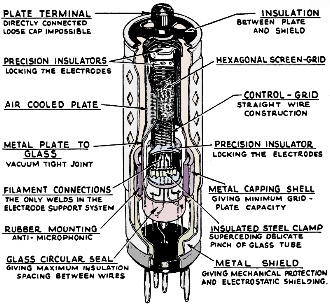

The entire story of the Catkin is told in the drawing here. A

really "new" tube.

By Robert Hertzberg

While American tube manufacturers have been content to produce "new" tubes by

adding grids and plates to old ones in wild confusion, the British have really done

something by eliminating 95% of the glass used in tube construction. The result

is stronger and far more uniform tubes than have hitherto been available.

The current sensation in European radio circles is the new "Catkin" all-metal

tube, which promises to revolutionize the tube manufacturing industry and to solve

a number of vexing problems of set design, construction, and operation. While glass

has not been eliminated entirely, the predominance of metal warrants the use of

the expression "all-metal."

In brief, the Catkin tube uses a copper cylinder, or container, in place of the

customary glass envelope, this container being the plate electrode. The other electrodes,

i.e., cathode and grids, are mounted within the cylinder in their usual relationships

to form triodes, tetrodes, and pentodes. As shown in the accompanying illustrations,

the bottom end of the copper container is sealed vacuum-tight to a short glass member,

through which the connection wires emerge and also through which the air is exhausted.

The entire lower end of this assembly is supported in the base by a built-in circular

rubber mounting.

While this type of construction has been used for many years in high-power transmitting

tubes, its application by the British General Electric and Marconiphone companies

to the receiving field is worthy of commendation. The name "Catkin" is a coined

word based on the laboratory slang word "cat" for "Cooled Anode Transmitters," a

"catkin" thus being a diminutive "cat." In transmitting work, where the plate power

dissipation is very great, the copper cylinder is cooled by water circulating around

it in a jacket. In the new Catkins the mere air circulation is sufficient to bring

the overall operating temperature well below that of vacuum type tubes, wherein

the very vacuum between the plate and the surface of the glass bulb makes the problem

of heat radiation very difficult of solution.

Here is the new English "Catkin" alongside an American type 24,

screen-grid tube.

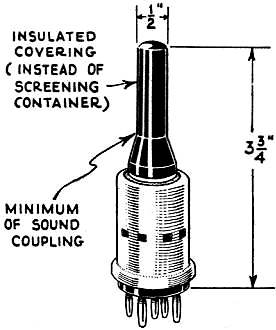

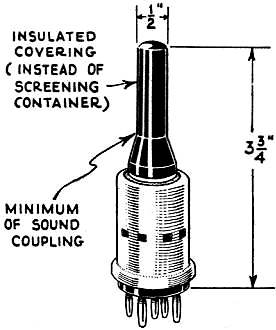

Microphonics-suppressing tube.

Vastly greater rigidity of internal construction is possible with the Catkins

than with glass tubes because the electrode structure can be braced firmly at both

ends by means of insulating spacers that actually touch the inner surface of the

copper "plate" cylinder. Not only does this arrangement practically eliminate microphonic

effects, but it also permits a degree of uniformity in manufacture sadly lacking

in conventional tubes; particularly tubes with a number of critically spaced grids.

In fact, uniformity of characteristics is the main merit claimed for the Catkins,

the tubes, electrically, being the general equivalents of standard British types.

The general-purpose triode and the output pentode of the Catkins series do not

require an external cover or shield, and full advantage is taken of the effective

cooling action of the exposed "plate." These tubes have a conventional base with

apparently nothing but a stubby piece of copper sticking out of the middle. In the

R.F. tetrodes an external shield of familiar appearance is employed. This is of

the same diameter as the base and is permanently attached to it; no separate tube

shields, as we know them in America, are needed.

An incidental departure in construction is the elimination of the usual pressed

glass bead in which the support wires for the electrodes are sealed; instead, the

Catkins use mica, the assembly at this point being braced by a steel clamp.

Providing the metal-to-glass vacuum seal proves satisfactory, it is easy to see

that the Catkins will enjoy widespread popularity and application. The manufacturers

claim they can be dropped six feet on to a concrete floor with but small risk of

either mechanical or electrical damage. The admittedly superior internal electrode

bracing and the built-in rubber mounting should at least do away with the terribly

annoying microphonic howling due to loudspeaker reaction, and should make the tubes

last longer than usual. The greatly reduced overall size is also an important factor.

For portable and mobile radio installations of many kinds, the Catkins possess

obvious advantages: tubes of this kind would give American manufacturers of auto-radio

receivers a wonderful sales "talking point" and would enable them to keep their

sets sold with fewer service worries; it is no secret that some of the new trick-combination

tubes are altogether too critical for bouncy automobile service. For airplane use,

something of the sort is certainly needed to stand the terrific shock of repeated

landings.

At the time this issue of Radio-Craft went to press (the middle of June) no Catkins

were available in the United States, and none are expected, except, perhaps, as

samples. If any American manufacturers grab the idea and turn out some tubes, for

experimental purposes, if nothing else, we will be glad to herald their efforts

in this magazine.

Posted January 9, 2024

(updated from original

post on 11/10/2015)

|