|

October 1935 Radio-Craft

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Craft,

published 1929 - 1953. All copyrights are hereby acknowledged.

|

Before there was radio, it really

didn't matter much how much electromagnetic energy at any frequency was spewed into

the air and into electric wires as long as the amplitude was not great enough to

physically damage affected equipment. There was no need for an FCC or unintentional

radiation limit regulations. It was not long after radio came along that the presence

of electromagnetic interference (EMI) made itself painfully obvious due to its presence

on audio as static. Motor brush arcing, electrical atmospheric phenomena (lightning,

meteors), switching on and off of circuits, intermittent connections, nearby radio

spurious emissions, high voltage transformers, and in this case, neon lighting were

among the sources quickly identified. Depending on the size of the sign and length

/ diameter of the tubes, the voltage needed to trigger the neon gas into electroluminescence

could be 12 kV or even more. At that level, especially with outdoor applications

subject to high humidity and water condensation, even minor breaches in insulation

can permit arcs to form between conductors and metal frames.

I clearly recall having received my first high voltage burn many moons ago while

servicing an outdoor neon sign for a store in a strip plaza in Annapolis, Maryland.

The next one occurred while troubleshooting a CRT power supply for a Precision Approach

Radar (PAR) display in my USAF shop's MPN-13 mobile radar unit. It must have been

that second one that finally taught me to be more careful since I don't think I've

gotten whacked by anything more than 120 V since then ;-)

The "Neon" Interference Problem

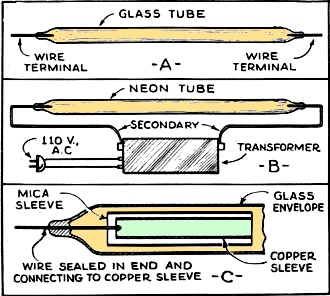

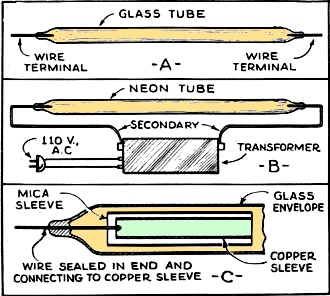

Fig. A - A typical neon sign display - indoor and outdoor.

The interference set up by neon signs involves problems which the Service Man

does not ordinarily encounter.

J. Albert Lynch

A growing source of radio interference is the increasingly popular neon sign.

In many cases the interference is so bad as to entirely ruin radio reception in

the immediate vicinity while the sign is in operation.

The neon sign, from a practical point of view, is extremely simple. In order

to service these signs for radio interference we need simply a very elementary idea

of the construction and contents of the completed tube, a fair idea of the construction

of the entire assembly, and a thoroughly sound idea of the wiring and sources of

trouble.

Our first example of a neon tube (Fig. 1A) will be a length of glass tubing

about 1/2-in. in diameter, and approximately 13 ins. long. We will now insert a

wire into each end of the tube, seal off the ends, apply a vacuum pump and then

after pumping, inject the required amount of neon gas and seal off the glass. We

now have a simple neon tube. If we now connect a transformer, rated at several thousand

volts, to these wire terminals (Fig. 1B) we will find that we have the usual

red-glowing neon tube. We would now notice that the glass, except at the extreme

ends, remained cool when operating. The ends would get quite warm and the wires

extending inside the tube would, because of the electronic bombardment going on

inside the tube, wear down and be short lived. For that reason instead of inserting

a wire inside the tube we will now build up an electrode which will consist (Fig. 1C)

of a metal plate surrounded by a mica sleeve inserted inside a glass envelope. A

wire is now attached to the copper plate, brought out one end of the glass envelope

and the envelope sealed off at that end, the other end being left open for attachment

to the glass tubing used for the desired outline or letter. We now have arranged

a terminal sufficiently large to give a reasonable life and so arranged as to keep

cool.

As a summary, the neon letter is simply a glass tube, shaped as desired, with

an electrode at each end, from which the air has been removed and the required amount

of gas inserted. This is all that the average Service Man needs to know about the

tubes themselves, as the actual building of the tubes is a separate trade in itself.

Window Signs

Fig. 1 - Some details in the design of neon signs.

Fig. 2 - The construction of the sign in Fig. A.

We will now take a typical window sign (Fig. 2) and follow its construction

and installation. In this sign (Figs. A and 2) the letters in the word Logans are

approximately 4 1/2 ins. high, and in the word bar approximately 8 ins. high. The

border outline is approximately 8 ins. larger than the letter assembly. The layout

man in the sign shop, usually the sign painter, lays out a full sized pencil sketch

of the sign, including a notation of the color, or colors desired, i.e., wording

red, border blue, all red, - red and gold or whatever combination is desired. The

sketch is then sent to the glass blower; or, more frequently, to an outside plant

specializing in neon tube work. The glass blower then shapes his glass to the pattern,

sending back the units complete and ready for lighting. In this case, the assembly

and outline is approximately as in Fig. 2. We receive from the glass blower

three separate and complete units, border - Logan's - bar, anyone of which can be

used alone, but which we now wish to shape into one assembly. Each unit is a continuous

length of tubing with an electrode and wire terminals at each end. These units must

be connected electrically in series and we will find the electrodes so shaped as

to each be headed toward the electrode to which it is to connect. The circuit is

as follows, one end of transformer secondary to one end of border unit, other end

of border unit to one end of unit Logans, other end of unit Logans to one end of

unit bar, other end of bar unit to second terminal of transformer secondary, making

a complete series circuit.

Radio Interference

We now come to radio interference. This may be roughly divided into primary and

secondary. Primary interference is caused usually by pick-up in the primary of the

transformer, by the lines feeding into transformer, or, by a defective transformer.

If the sign is on a separate circuit., at least a different circuit from that of

the radio, and the sign is fed by a circuit run in a well-grounded metallic conduit,

you will rarely have trouble from the primary source unless the transformer is defective.

A line filter connected near the transformer and rated at 5 A. per transformer will

usually be a positive check against primary interference provided that we have checked

as to separate circuit and grounding.

The secondary source of interference is usually from either a defective secondary

coil, pick-up from secondary wiring, pick-up from tubes, partial ground or short

in secondary wiring, pick-up from back bends in tubing caused by difference in potential

in these sections of glass, pick-up from suspension wires from which window signs

are hung, or pick-up from metallic objects, such as metal ceiling, pipes, and so

forth, in the immediate vicinity of the sign. The solution here is to ground out,

or neutralize all points of possible pick-up. I suggest that the Service Man proceed

as follows: always remembering that he is working on a simple electrical system

that simply happens to be of high voltage, and with his theory of radio in mind,

always looking for the most logical point in the particular installation from which

he can expect radiation. We will first check both types of trouble on a window sign.

The procedure is as follows; Turn the sign on to see if it is operating properly.

If the sign runs fairly steady and without any serious sign of fluttering of the

tubing, you can assume that as far as the tubing and transformer go you are O.K.

If the sign only lights dimly, or in parts, you can assume a broken unit. The units

can be tested with a neon tube tester that can be obtained, complete with directions,

from any tube supply house, or by the following method: take a piece of high tension

cable and jump across each unit in turn. When the defective unit is jumped the balance

of the sign will light. The jumper must of course be connected from the wire of

one of the electrodes at one end of the unit to the wire on the other end of the

unit. If the entire assembly flutters badly, does not light at all or only in part

and we find no defective unit, then it must be the transformer. Disconnect the secondary

leads and with a high tension wire for a jumper touch the two secondary terminals.

A good hot spark should result. If no spark results, or a weak one, get a new transformer.

Most transformers above 7,000 V. are center tapped. In that case they should be

tested from the case to each terminal in turn. This will test the two secondary

coils. assuming that the sign is operating properly. We will now proceed to clear

the radio interference. As we proceed, if any one of these clear the trouble, you,

of course. go no further. First, make sure that the sign is running off a different

circuit than the radio; second, make sure that the case of the transformer is grounded;

third, tie several fine bare wires, (about number twenty-five) across the face of

the glass; fourth, cross secondary leads coming from transformer to unit; fifth,

break wire suspending sign in window and insert about a 6 in. section of waxed cord

or ordinary twine; sixth, cut a 5 A. line filter in the primary circuit of the transformer

as near as possible to the transformer. There is one type of installation that is

liable to be quite troublesome, that is, where a sign is hung on a leaded glass

window. In this case I would first solder fine wires to the leaded sections at four

or five points near the sign, tie these wires together and run them to the nearest

water pipe for a good ground, then see that the tubing is kept as far as is reasonably

possible from the leaded glass.

With outside signs we proceed about the same as with the window sign. If the

sign is on a flasher, filter the motor circuit of the flasher, and if necessary

filter each primary circuit across the breaker points in the conventional manner.

In general check all installation for these possible points of interference:

1 - Separate line circuit (at least separate from radio).

2 - Transformer and sign cases grounded. 3-Flashers filtered.

4 - Keep aerial away from sign.

5 - Supply line to sign in metallic conduit and grounded.

6- Fine wire ties across face of units.

7 - Loose secondary connections, or arcing to case of sign or other wire,

In special reference to window displays.

8 - Crossing secondary feeders.

9 - Cutting in insulators in suspension wires to stop further radiation from

this point.

Posted May 31, 2022

(updated from original post on 11/23/2015)

|