|

November 1929 Radio-Craft

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Craft,

published 1929 - 1953. All copyrights are hereby acknowledged.

|

Vreeland Corporation was an

early radio manufacturer located in Hoboken, New Jersey, with multiple patents on

file for innovative circuits. The

Vreeland band

selector system mentioned here was originally filed in the U.S. Patent and Trademark

Office in August of 1927 and had not been awarded by the time of this November 1929

article in Radio-Craft magazine. In fact, it wasn't until five years later,

in 1932, that the patent was finally assigned. The official description reads in

part, "The general purpose of the invention is to receive the component frequencies

of such a band with such uniformity as to avoid material distortion of the modulated

wave, and to exclude frequencies outside of the band which the system is designed

to receive. Another purpose of the invention is to provide means for shifting the

position of the band in the frequency scale at will, by a simple adjustment, so

that the system may be readily adapted to receive modulated waves of any desired

carrier frequency, including the side bands of such modulated waves." That sounds

to me like a standard heterodyne system with selective filters. It seems the filter

characteristic with a wider inband region and sharp cutoff is what make it unique.

One line in the patent states, "... a radio receiving system embodying a plurality

of my [emphasis added] band selector units, one being

associated with a collector ..." Note the use of the possessive "my," by Frederick

K. Vreeland, which I doubt would ever appear in a contemporary patent filing. Mr.

Vreeland authored books such as Maxwell's Theory and Wireless Telegraphy as well as

Camp Buildings and Scout Shelters for the Boy Scouts

of America.

Building a 1930 Electric Receiver

A super-sensitive set of simple construction

incorporating the latest principles in radio design. A super-sensitive set of simple construction

incorporating the latest principles in radio design.

By Clyde J. Fitch

The modern factory-built radio set is so far advanced in design that one hesitates

now to construct his own; yet with a little care and patience a commercial-looking

job can be turned out at home that will excel the latest commercial models. The

receiver shown in the accompanying illustrations was designed for sensitivity, tone

quality, and ease of operation; while it incorporates new features not found in

other receivers. It was built for installation on the Florin Lenox estate in the

Adirondack Mountains, a location which is immune from interference of any kind except

an occasional thunderstorm; consequently unusual selectivity was not required. However

this set compares with the best in selectivity.

New

Locals with a 2-foot aerial! Absolutely no batteries about which to think twice.

The power of two '10s in push-pull at the flick of a switch and turn of a knob!

All station selection obtained by the turn of another knob. "Wind-your-own" selectivity!

Three stages of screen-grid amplification (guaranteed non-whistling) and a screen-grid

"power detector." And audio quality with a realism which will startle the critical

ear. When we heard that our old friend Clyde J. Fitch had built, at moderate cost,

a receiver which met these qualifications, we asked Mr. Fitch to tell you all about

it. And so - we not take pleasure in presenting

"The 1930 Electric Receiver"

Engineering Features

It comprises a Vreeland band-selector system which feeds into a three-stage untuned

R.F. amplifier using A.C. screen-grid tubes and iron-core untuned radio-frequency

transformers. A screen-grid detector is used with one stage of resistance-coupled

audio amplification and one of push-pull using type '10 power tubes. This makes

seven tubes in all, four screen-grid type '24, one type '27, and two '10's; not

counting the '81 rectifier and '74 voltage regulator used in the power pack.

The band selector, the theory of which is explained below, passes a 10-kilocycle

band of wavelengths at any location in the broadcast spectrum, depending upon the

adjustment of the tuning dial. This allows the carrier-wave with its accompanying

"sidebands" (which represent the music), to pass through from the antenna to the

amplifier uniformly, giving distortionless reception in this part of the set. This

is true also of the radio-frequency amplifier, which employs the old Acme iron-core

transformers, used several years ago in that company's reflex sets. These transformers

give very efficient amplification over the entire broadcast band, and associated

circuits do not oscillate ("'whistle," howl, etc.) at any point on the dial when

used with screen-grid tubes. Two type-R3 transformers, (RFT1 and RFT2 in Fig. 1)

with one type-R4 (RFT3), gave the best results; the type-R2 was found unsatisfactory.

No doubt there are other iron-core radio-frequency transformers that may be used

instead, in case the constructor has difficulty in finding the Acmes.

The "band-selector" detail. Varying the number of turns in L

determines the selectivity of the receiver.

Fig. A - Front of set, showing panel layout: note convenient

adaptability to any panel size. The "volume control" is R5; while C2-C3 is the "station

selector" or tuning knob. A light, rigid, monel-metal sub-panel is used.

An optional but experimental design of the "band-selector;" Selectivity

is governed by C; R closes the circuit.

The use of a screen-grid detector with a stage of resistance-coupled audio amplification

is another feature that gives high, distortionless amplification.

Here (in New York City) the set picks up locals with an indoor antenna two feet

long; with no antenna it picks up nothing, since it is well shielded. Quality is

unusually good, for the reasons mentioned above, and operation is simple, as the

illustration (Fig. A) shows; one knob (C2-C3) being used for tuning, and the

other (R5) for a volume control (which is easy to regulate because it does not detune

the set or cause it to oscillate and squeal or howl).

In the illustrations, Fig. A shows the front view; Fig. B the top with

the covers of the shield cans removed; Fig. C the rear, and Fig. D the

power pack. The panel was cut to the size shown, merely to fit a special cabinet.

Construction of the Set

The metal base should be made first; that illustrated here was a sheet of monel

metal 13 1/2 x 29 1/2, inches and 1/32-inch thick with the corners cut out to a

depth of an inch each way and the sides bent down and soldered at the corners, making

a "pan"11 x 27 x 1 1/4·inch deep. This work should be done by a tinsmith. Aluminum

may be used instead, but it should be at least 1/16-inch thick, as it is mechanically

weaker than monel metal; since aluminum cannot be soldered easily, the corners should

be strengthened with brass angles bolted in place. Even a good wooden baseboard

may be substituted.

Dimensions for drilling the base are not given, as these will depend upon the

particular parts used. The general layout shown in Fig. B can be followed without

difficulty. The sockets are mounted with their terminals underneath; so that practically

all the wiring is below, out of sight and well protected. With the exception of

the socket holes, the drilling of the base may proceed as the set is being assembled,

by the use of a hand drill.

The Band Selector

The band-selector coils L1 and L2 consist each of 85 turns of No. 28 wire wound

2 inches in diameter, with a center tap, as detailed in Fig. 2. (Hammarlund

space-wound coils were used.) They are clamped by two strips of Bakelite, which

carry the three terminals for the two end connections and center tap. Brass angles

are used to mount them in the proper relation to the metal base, inside the shield

cans as shown.

The two 0.00035-mf. tuning condensers C2, C3 are mounted on the shield cans as

illustrated; both on the same shaft and with a single-dial control.

The 23-plate "midget" antenna coupling condenser C1 is mounted on an insulating

strip of Bakelite which is fastened to the upper left-hand corner of the right-hand

can, (Fig. B). The 9-plate "midget" trimming condenser C4 is mounted directly

on the other shield can, as shown in the same figure.

The coupling coil L3 consists of 4 1/2 turns of wire wound on a vacuum-tube base.

This is plugged into a standard socket, mounted on the set base as shown. The two

ends of the coil are connected to the filament prongs of the tube base. This completes

the band-selector parts; wiring and adjustment will be described later.

Many explanations have been published about this new method of radio tuning,

but the practical man wants more practical data and a clearer understanding of the

theory without wading deeply into mathematics; therefore, let us begin at the beginning.

and explain why bandpass tuning is necessary for undistorted reception.

Suppose we start at the transmitter, but forget the old idea of modulated carrier

waves and look at the situation from a different viewpoint; a viewpoint where even

the layman can get a clear insight into radio transmission. From our method of heterodyne

reception (as used in the superheterodyne receiver) we know that when two alternating

currents of different frequencies, F and F1, are combined, two other frequencies

are produced, equal to (F + F1) and (F -- F1); making four distinct frequencies

in all. (Harmonics of these will also appear, but they are useless for our purpose.)

"Modulation" Simply Explained

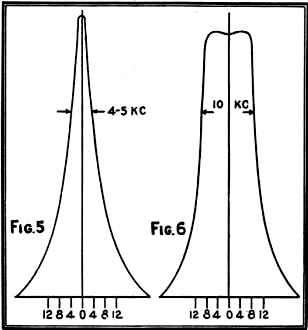

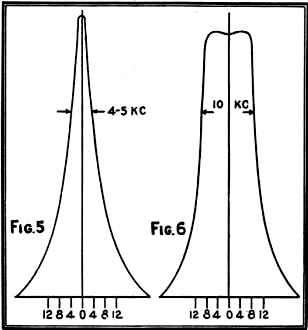

At left is illustrated the sharp "cut-off" by which "volume distortion"

is caused in ordinary tuned-radio-frequency sets; at the right the desirable "flat-top"

effect which may be obtained by proper "band-selector" design.

Since radiation of electric energy from the transmitting antenna must take place

at very high frequencies to be efficient, a high-frequency generator is used at

the transmitter. For broadcasting, frequencies from 500,000 to 1,500,000 cycles

per second are used, each station having its own assigned operating frequency. This

frequency is called the carrier-frequency, or "carrier wave." We will call this

frequency f. Now, suppose we combine with this carrier frequency, f,

the sound-frequencies (or music and speech-frequencies produced in the studio) and

see what happens; keeping in mind that the music- and speech-frequencies range from

about 50 to 5,000 cycles per second. We will call these the audio-frequency band,

or just "AB."

From the above heterodyning action, we learn that four distinct frequencies will

result; namely, the carrier-frequency f, the audio-frequency band AB, and

the bands (f + AB) and (f-AB).

The audio-frequency band AB will not be radiated from the antenna, because its

frequencies (50 to 5000 cycles) are too low for efficient radiation. The carrier

frequency, f, will be radiated as will also the frequencies (f + AB)

and f - AB). These latter two are called the sidebands, and they contain

all the music and speech, because they contain the audio-frequency-band component

AB.

In explaining radio transmission to a layman, we can simplify this still further

and merely state that radiation takes place at very high frequencies; therefore

at the transmitter we add a high frequency, say a million cycles, to the sound frequencies,

so that they can be radiated, and later remove the high frequency at the receiver.

The ordinary person will grasp this heterodyne idea much quicker than he can grasp

the modulated-carrier-wave idea.

We see from the above that a group of frequencies (namely, f, f

+ AB, and f - AB) are radiated from the broadcast transmitter having a

maximum difference of I plus and minus 5000, or a total separation of 10,000 cycles,

or 10 kilocycles. For example, using a carrier of 1,000,000 cycles, a band of frequencies

from 995,000 to 1,005,000 cycles will be radiated. Our receiving set must therefore

tune in all these frequencies at once in order to receive all the music; or the

sopranos will be lost in the ether, and this might not always improve the programs.

Hence, the use of a band-pass or selector.

Fig. B - An airplane view of "The 1930 Electric Receiver."

Simplicity is a key-note. A convenience is socket L3 into which the coupling coil

of the "band-selector" is plugged. Condensers C1 and C4 are mounted on the ends

of the aluminum shield cans.

A view of the interior of S3. looking from the front of the set.

The fixed condensers are soldered to each other. To obtain maximum efficiency from

the R.F. transformers, they are mounted away from all metal work. There is no interaction

between these units.

The power unit. Figures 709, 854, and PF281 are parts numbers.

The power-transformer primary is provided with taps for line-voltage compensation.

One voltage regulator, V9, is used.

Fig. C - Rear view. The arrangement of the binding posts

is clearly shown in this illustration. Tube shields which thread on were used to

prevent noisy contacts. Note the neatness of this powerful screen-grid-type radio

receiver. The parts used are standard.

Details of "band-selector" coils. (Two are required.) The use

of different tuning condensers will necessitate a different number of turns.

The ordinary radio set must be selective in order to tune in a single station

without interference from others. Tuning must be sharp. But sharp tuning cuts the

sidebands; it weakens or eliminates the higher audio frequencies, and causes the

music to sound deep and muffled. Instead of tuning in the complete ten-kilocycle

band of waves, it covers a band of only about four or five. This is shown in the

response curve of Fig. 5, which only has good response over a 4-kc. band. Each

tuned circuit in the receiver has one definite "peak" where the response is maximum,

and this is adjusted to be in resonance with the carrier-frequency.

Design of the Selector

The band-pass selector has two tuned circuits, loosely coupled together. The

two circuits give two peaks, adjusted so as to be dose together, making a somewhat

flat-topped graph 10 kilocycles wide, as shown in Fig. 6. The curve has two

small humps at the top c used by the two peaks of the two circuits. The sides slope

down about as in the curve of Fig. 5, but the width at the base, using carefully-designed

circuits, is no greater than in the former curve. Therefore, selectivity is as good

when using the band selector as it is with the ordinary method of tuning, and it

responds to the entire band of transmitted frequencies more evenly.

Fig. 7 shows the circuit diagram of a band selector; this is the system

used in our complete schematic, Fig. 1. The two tuned circuits are indicated

at A and B, and are coupled together by the common inductance L. The circuits A

and B have each the same sizes of coils and condensers, and are designed to cover

the broadcast range; therefore any good broadcast coils and condensers may be used.

Magnetic coupling must not exist between the coils; therefore they must be thoroughly

shielded.

The degree of coupling is determined by the value of the inductance L; this,

also, determines the spacing between the peaks of the two resonance curves, and

consequently the width of the band of frequencies that it will pass. If L is increased,

coupling is increased and the width of the curve, Fig. 6, is increased. If

L is decreased, the width of the curve is decreased. The correct value of the coupling

inductance L will give us the desired 10-kc. width. 4 1/2 turns, wound on a tube

base, is about the correct number. Several such coils may be made, ranging from

2 1/2 to 6 turns, and are easily interchanged by mounting them in a standard socket.

The smaller the coil, the greater the selectivity. You can therefore adjust the

selectivity to suit your particular requirements.

The width of the curve (Fig. 6) does not remain constant over the entire

broadcast band, but varies with the frequency. Using the circuit of Fig. 7

with inductive coupling, the width increases with increase of frequency; because

the reactance of the inductance L is greater at the higher frequencies, and the

degree of coupling is greater. Hence it may pass only the correct10-kc. band at

the upper wavelength settings, but a 10-kc. band at the lower. As this will be objectionable

in some localities, the system shown in Fig. 8 may be employed instead.

The only difference is that the two circuits are coupled by a common capacity

C, instead of by an inductance. (When using the coupling condenser C, the grid circuit

of the first tube in the R.F. amplifier will be open. The resistor R, of about 2

megohms, should be connected across the condenser C.) This gives just the opposite

effect to that obtained with the inductance; the larger the capacity, the less the

degree of coupling, and vice versa. A coupling condenser of 0.025-mf. is about the

correct size. This also may be mounted into a tube base, together with the resistor

R, and plugged in the socket in place of the coupling coil.

With capacitative coupling, the coupling decreases with increase of frequency.

There-fore the selectivity is greater at the lower wave-lengths than at the higher,

which is just the opposite effect to that obtained with the inductance. Different

sizes of condensers may be tried to get the correct balance. (Perhaps a combination

of capacity and inductance may be found to give a 10-kc. curve through the entire

broadcast band.)

Summing up, the receiving aerial picks up all the stations on the air, but the

band selector allows only the band of frequencies transmitted by anyone selected

station to pass through it and into the R.F. amplifier.

R.F. Amplifier and Detector

The radio-frequency amplifier and detector is a complete unit in itself and wired

independently. The mounting of the apparatus is indicated in cross-section in Fig. 3,

and the reproduced photographs clearly show the unit and its location on the base.

The copper shield can (S3) of a Remler "Infradyne" intermediate amplifier was used

by the writer, and was just the correct size for inclosing the parts; a metal top

was required, however, measuring 4 by 16 inches. All the parts are mounted on this

top, so that it can be removed for inspection or repair without removing the can

from the base. The can is 2 3/4 inches deep inside, and can easily be made up of

sheet copper.

The sockets are equally spaced on the metal top, as shown, while the radio-frequency

transformers are mounted below them and away from the can. Below the detector socket

is fastened a strip of bakelite supporting one of the by-pass condensers; the other

condensers are soldered together and mounted between the sockets. Eleven one-microfarad

condensers in all are used in this unit. Condensers of this capacity were selected

to by-pass thoroughly all the connections in each stage, so there would be no tendency

to oscillate due to coupling of the common connections. In ordinary sets this effect

is negligible; in "high gain" receivers using screen-grid tubes "common coupling"

becomes a serious problem.

The wiring of this amplifier is clearly shown in the complete schematic diagram,

Fig. 1. The space enclosed by dotted lines S3 indicates the connections inside

this unit.

The 100-ohm resistor R1 , between the R.F. cathodes and ground, gives a 1 1/2-volt

"C" bias on the R.F. control grids. The 5000-ohm resistor R2, connected between

the detector cathode and ground, gives 5 volts bias on the detector control grid.

These resistors are mounted in the amplifier unit but are not shown in Fig.

3.

Schematic diagram of the "1930 Electric Receiver." The shield

cans for the various units are indicated by dotted lines. Resistor R6, once adjusted,

need not be changed unless the characteristics of V4 change appreciably. A dynamic

reproducer may be substituted for the electrostatic reproducer indicated. Resistors

RB, R9 prevent undesirable oscillation in the push-pull stages. Every by-pass condenser

shown should be used.

Construction of the R.F. transformers. The secondary is arranged

in "pies" to reduce self-capacity to a minimum. "Flat" response is obtained by variation

of the number of primary and secondary turns.

Fig. D - Perspective view of the power pack, which should

be mounted at a distance from the set chassis. Power transformer PT should be at

the point most distant from audio transformer AFT. Filter chokes with generously-proportioned

cores greatly help to obtain humless operation.

Connections to the amplifier unit are brought out through holes in the bottom.

There will be two heavy leads for the 20 1/2-volt A.C. supply to the heaters. Large

flexible wire should be used for these, as the current for the four tubes will be

7 amperes.

There are four other connections to the amplifier, colored preferably as indicated

in the diagram; blue for volume control (R5) regulating the screen-voltage of the

R.F. tubes; brown, for detector screen-voltage control (R6); green for the detector

plate; and red for the 180 volt "B" supply. The shielded control-grid leads are

brought out through the top, as shown in the photographic illustrations. The first

one comes from the band-selector shield can, as will be seen from Fig. B.

Hand-Made "R.F.T's."

Suitable untuned transformers for the R.F. amplifier can be constructed according

to the illustration, Fig. 9. The core consists of strips of very thin silicon

steel transformer laminations 1/2" wide by 2 3/8" long, stacked up to a thickness

of 3/16", as shown. On each side of this is placed a wooden form 5/32" by 1/2" by

2 3/8" long, so that the finished core assembly is 1/2" square. It is bound together

with a few wrappings of waxed paper.

The primary winding is "random wound" over one half of the core length. No. 38

S.C.C. wire is used. (This is indicated in the illustration for clearness as a single

layer.) The secondary is also of No. 38 S.C.C. wire wound in ten sections, or "pies,"

equally spaced over the entire length of the core as shown. A layer of waxed paper

is placed between the two windings.

The wavelength band which the transformer efficiently covers depends upon the

number of turns in the primary and secondary. For the first and second stage units,

RFT-1 and RFT-2, the primary should have 35 and the secondary 83 turns.

For the third stage, RFT-3, the primary should have 26 and the secondary 43 turns.

As there will be some variation in these transformers due to different qualities

of iron, it may be necessary to add or subtract wire from both primary and secondary

to obtain the best results. This can easily be done experimentally after once operating

the set to determine if it amplifies uniformly over the entire broadcast range.

The Audio Channel

The audio amplifier comprises one stage using resistance-capacity coupling (V5)

and one with push-pull (V6-V7). Resistance-capacity coupling was selected for the

first stage, because it is the most efficient method when used with a screen-grid

detector. The plate-circuit resistor R3 used at a plate voltage of 180 is 250,000

ohms, which allows about one milliampere to pass through the detector with a grid

bias of 5 volts and a "screen" voltage of 75. The screen voltage is adjusted by

the 500,000-ohm potentiometer, R6, mounted on the base. When once set, this requires

no further adjustment.

The plate resistor R3, grid leak R4, and 0.05-mf. coupling condenser C17 are

mounted on the base, as shown. The locations of the '27-type A.C. tube, the two

'10s, and the input push-pull transformer AFT are clearly illustrated.

Underneath the base are mounted the detector R.F. choke L4; the 0.0005-mf. by-pass

condenser C16; the 1500-ohm "C" bias resistor R7, for the first audio tube; the

two 50,000-ohm stabilizing resistors R8 and R9, in the push-pull grid returns; and

the by-pass condensers. A 1-mf. condenser C18 shunts the 180-volt and ground terminals;

2-mf. (C19) is the by-pass capacity for the 90-volt output; and 1-mf. (C20) by-passes

the first-audio "C" bias resistor.

The two plate terminals 1 and 2 of the output tubes are mounted on a Bakelite

strip at the right end of the base, while the other terminals are along the back,

arranged as indicated in Fig. B.

Parasitic Oscillation

The center tapped output choke used with this set is mounted in the cabinet with

the reproducer. It has a value of 400 henries and a carrying capacity of 60 ma.

(To prevent parasitic oscillation the halves are balanced at the factory for absolute

electrical symmetry on both sides of the center tap.)

It is fitting to observe at this moment that a primary fault in average push-pull

circuits is that malady variously known as "feedback," "interference," "harmonics,"

etc.; in plain words, parasitic oscillation. It manifests itself in an above-normal

plate current; and it may, or it may not, be accompanied by a high-pitch whistle,

and distortion. It does not make any difference whether it causes distorted reception,

the idea is that a fault exists which is going to cost the owner some money unless

it is remedied. As exceptional precautions have been taken in the design of this

receiver to prevent parasitic oscillation in the push. pull stage, there is almost

no likelihood of trouble from this source. In addition to measures mentioned above,

the author points out the use of two stabilizers or oscillation suppressors, R8

and R9, in the "grid return" lead of each power tube. This connection is possible

only when the input transformer secondary has a balanced, two-section winding. (To

by-pass these resistors would be to defeat their purpose. The "grid bias resistor"

R14 serves an entirely different purpose and it is necessary that this unit be properly

by-passed, - the purpose of C25.) A single resistor in a single return lead would

be "common" to both tubes and the "isolation" desired would not be obtained.

By carefully following the diagram, Fig. 1, you should have no trouble in

wiring the set. Be sure to use large cable connections for the 7 1/2-volt filament

and the 2 1/2-volt heater supply. The practice of transposition is followed with

all filament leads; that is, they are twisted to eliminate any possibility of an

induction hum. The metal base is grounded, also the "B-" lead from the power pack.

The band-selector connections should be as direct as possible. The leads should

be well insulated and securely soldered. After the panel is put in place, the condenser

shaft lined up and dial mounted, the set is ready for operation.

Type '45 or '10 Power Tubes?

During the early stages of the design, the question arose as whether type '45,

type '10 or type '50 tubes should be used. Each has its advantages and disadvantages.

(The constructor is recommended to experiment with the necessary power equipment

for type '45 tubes, where the power-handling ability of the type '50 tube is not

needed for driving dynamic reproducers.) Type '10 tubes, however, were selected

because it was intended to use an electrostatic reproducer, the polarizing potential

for which would be available with the operating voltages of type '10 tubes; whereas

the use of type '45 tubes, which do nor operate at such high plate potentials, would

necessitate a special "polarizing" unit for the electrostatic reproducer. (The "undistorted

power output" of two '10s is about the same, at the voltages shown, as that of two

'45s at 250 volts, plate.) The question of single or push-pull operation was settled

almost instantly; as the push-pull arrangement, on many counts, is far superior

to a single tube. It will be noticed that coupling condensers have been dispensed

with; this arrangement is possible only when the output is push-pull, for the direct

current (which would ordinarily circulate through the reproducer winding or matching

transformer primary, when contact is made directly to the plate - in the case of

"dynamic" and "electro-magnetic" reproducers), is balanced out by this connection.

What the constructor is most interested to know is that the frequency-discrimination

of coupling condensers has been eliminated and better reproduction results.

Where "electrostatic" reproducers are used, it will be an advantage to connect

directly to the plate, as will be observed from consideration of the output connections

of Fig. 1. Of course, the use of a dynamic reproducer is optional; its two

leads being connected to output posts 1 and 2.

The Power Pack

Parts Required for "1930 Electric" Receiver

The power pack (Fig. D) is also mounted on a metal base. This base (when

shaped) is 10" x 18"x 1 1/2" deep. Only one illustration, besides the diagram (Fig. 4)

is given as this unit is comparatively simple to build. The list of parts gives

the details of the apparatus used in the power pack, all of which is mounted on

top of the base.

Each of the filter condensers (C21-22, C23-24) consists of two 4-mf. units. Two

of these are connected in series, giving a total capacity of 2 mf. across the highest-voltage

side. One of the other 4-mf. sections is connected across the 425-volt lead and

the fourth across the resistance bank.

The latter consists of one 3000-ohm, 100 watt, resistor R10; one 2000-ohm, 100-watt,

resistor, R11; one 3000-ohm, 20-watt, R12; and one 4500-0hm, 20-watt resistor, R13;

all connected in series as shown and mounted on a small Bakelite panel. A 1000-ohm,

100-watt, "C" bias resistor R14 is also mounted on this panel, and by-passed by

the 1-mf. condenser C25. Be sure to use well-insulated wire for making all connections.

Resistor R10 functions as an over-all voltage control, "absorbing" the potential-difference

between 180 and approximately 400 volts.

Choke L5 has a greater current carrying capacity than L6. Its rating is 120 ma.,

20 Henries, and D.C. resistance of 210 ohms; L6 being rated at 60 ma., 50 Henries

and 600 ohms. It will be seen that the power tubes derive their plate supply through

L5, but not through L6. This connection results in absolutely humless operation

(so far as the filter is concerned) when the output tubes are in push-pull; a little

more filtration being desirable for a single-tube-output design.

The 110-volt A.C. connection to the power transformer passes through the switch

SW on the panel of the set. The filament connections between the power pack and

the set should be made with large wire; so that there will be no appreciable voltage

drop. The pack should not be placed too close to the set; because A.C. hum may be

picked up by the set if it is placed in the magnetic field of the power transformer.

This completes the assembly of the parts, with all the apparatus mounted, the

radio-frequency amplifier unit all wired and its leads coming out the bottom, through

holes in the base.

Adjustment and Operation

With everything hooked up properly, simply turn on the switch and the set is

ready for operation. To adjust the band selector, tune in a station and turn the

volume down. Then set the antenna-coupling condenser C1 at maximum and retune the

station while changing the trimming condenser. For maximum sensitivity, the two

tuned circuits must be in resonance; and this condition is obtained by carefully

adjusting the trimming condenser C4. A screwdriver may be used to adjust the two

"midget" condensers by cutting holes in the shields and slotting the shafts of the

condensers,

If the set is broad in tuning, decrease the capacity of C1 and readjust C4. In

this way, the correct capacity for your particular antenna can be found. A trimming

condenser for the first tuned circuit has been found unnecessary; but one may be

used to facilitate the adjustment. The adjustment should be tried at both upper

and lower ends of the scale.

The tubes also may be shifted around, for they vary slightly, and some work better

as a detector than others. The detector screen voltage should also be adjusted for

maximum sensitivity.

Using a good electrostatic or dynamic reproducer, this set will give unusually

good tone quality with very little A.C. hum; and you will be well pleased with the

ease in operation and sensitivity. With the '10 push-pull amplifier you can obtain

sufficient volume for any occasion. If preferred, '45 tubes may be substituted by

making changes to suit in the power pack.

Acknowledgement is made here of the courtesy of Mr. R. H. Siemens, chief engineer

of the Radio Construction Laboratories, who kindly provided laboratory facilities

and technical aid during the design and construction of the "1930 Electric Receiver."

Posted August 30, 2022

(updated from original post

on 12/18/2015)

|