|

November 1972 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Did you know that General

Electric introduced the first

silicon-controlled

rectifier (SCR) for commercial use? It was in 1957 when this article

appeared in Popular Electronics magazine. The SCR was one of the first

really high power devices in the semiconductor industry, not for its voltage and

power gain, but for its ability to switch very large currents on and off while having

a relatively low "on" voltage drop. This article gets into the basic theory, operation,

and application of the SCR. The S-band airport surveillance radar that I worked

on in the USAF originally used a vacuum tube thyratron to trigger the magnetron's

pulse forming network, but that tube was replaced with a solid state SCR circuit

that plugged directly into the original thyratron tube socket.

The How and Why of the SCR

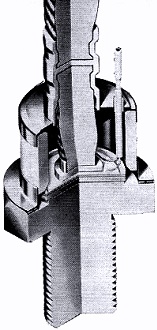

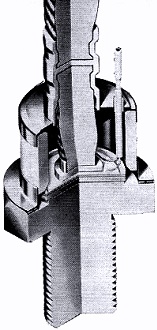

Cutaway view above of an SCR courtesy of International Rectifier

Corporation.

Principles of Operation and Applications of the Silicon Controlled Rectifier

By Joseph H. Wujek

When the semiconductor industry began to expand in the 1950's, transistors and

solid-state diodes and rectifiers quickly replaced their vacuum-tube counterparts

in many applications. Then as now, the complete transition from tubes to semiconductors

was not possible because of the limitations of the latter. In 1957, however, an

important step toward the goal of total replacement by semiconductors was taken

when General Electric Co. introduced the silicon controlled rectifier, or SCR.

Briefly, the thyratron permits the control of power in switching applications

with only a small energy loss in the control circuit. By applying a signal to a

control grid, the thyratron is made to conduct between a pair of electrodes (anode

and cathode) and remains conducting with no further excitation at the control grid.

In fact, in normal operation, the grid ceases to control the thyratron once conduction

begins. To stop conduction, the anode must go from a high positive potential to

near zero as in the phase reversal of a 60-Hz power line.

Fig. 1 - The transistor circuit at left is equivalent to

actual SCR at right.

The SCR performs in an analogous manner; and, in addition to the inherent improvements

in reliability and simplicity afforded by semiconductors, some of the kindred devices

of the SCR can function as turn-on/off systems to control bidirectional currents,

an impossible task for the thyratron and other vacuum tubes.

How It Works. The operation of the SCR is perhaps best understood

by examining the device's pnpn junction, shown in equivalent form by the two transistors

in Fig. 1. Assume that the control (gate) electrode is connected so that its

voltage is the same as, or slightly negative with respect to, the voltage on the

cathode. Transistor Q2 is cut off and only leakage current flows in the circuit.

If the gate voltage is made positive with respect to ground, the base-emitter junction

of Q2 becomes forward biased and Q2 begins to conduct. Moreover, Q1 also becomes

forward biased and conducts. As Q1 starts conducting, its collector current aids

in turning on Q2, just as collector current from Q2 assists in turning on Q1.

This mutual aid is a form of regeneration, or positive feedback. A point is reached

at which the switching action "runs away" from the control input and becomes self-sustaining.

In regeneration, Q1 and Q2 are operated at saturation, and the voltage drop from

the collector of Q2 to ground is the sum of the 0.7-volt base-emitter drop of Q1

and the 0.2-volt collector-emitter drop of Q2. (The voltages are for silicon transistors

only.) Thus, the switch exhibits a low voltage drop and requires no control input

power to sustain conduction.

To turn off the circuit, the current in the transistor bases must be internally

reduced to a level at which the current gain of Q1 and Q2 is insufficient to supply

the required currents. Since it is not practical to get into the transistor junctions,

the current in the emitter-collector branch is reduced. This is accomplished automatically

if the supply voltage is derived from an ac source. (The SCR is primarily an ac

device, although in dc applications it will serve as a "latch," or memory switch,

and remain conducting until the anode current is reduced or interrupted.)

The point at which the anode current of an SCR is sufficient to keep the device

conducting is called the holding current. The peak voltage (anode positive with

respect to cathode) at which the SCR does not undergo breakdown for given conditions

of bias between the gate and cathode is the the peak forward blocking voltage; this

is usually specified with the gate connected to the cathode through a low resistance.

The peak reverse voltage with the anode negative with respect to the cathode

is also specified with the gate connected to the cathode through a low resistance.

These diagrams show the steps in the fabrication of a silicon

controlled rectifier as made by General Electric.

Leakage currents increase with temperature increases and roughly double for every

10° C rise. In Fig. 1, the transistors cannot distinguish between currents

caused by leakage or from a triggering pulse. Hence, care must be exercised in determining

the temperature environment and external circuit conditions to prevent thermal turn-on.

Other unwanted turn-on mechanisms are the device's built-in junction capacitances

which provide paths for current when the anode-cathode voltage is changing. Current

through a capacitor is proportional to the voltage rate of change with time. A fast

changing voltage can introduce sufficient current to trigger the SCR. This parameter

is specified as the "critical time rise" and usually is given in V/μS.

The forward and reverse breakdown volt-ages have already been mentioned. Unless

some means of externally limiting the current is used, these breakdown voltages

will destroy an SCR. Except where severe transient voltages are present, the breakdown

voltages will present no problems if the specified ratings are not exceeded.

Parameters & Characteristics. If the SCR is to be intelligently

employed, it is essential that the user be familiar with the device's various parameters

and characteristics. These specifications are given in the manufacturer's data sheets.

In choosing an SCR, first check the maximum allowable ratings, including the maximum

current handling capacity which may be stated as average current or rms current

or both. To use either specification, the current waveform through the SCR must

be known.

The peak surge current, usually specified for a 60-Hz half-wave excursion, is

the current the SCR can handle on a low duty-cycle basis, permitting the SCR to

cool off between surges. These currents can be as much as 10 times greater than

the rms current. Such ratings are useful when the SCR is employed in "crowbar" operation

to discharge a capacitor bank.

Power ratings for the entire SCR, as well as for the gate circuit are often stated.

These ratings depend on ambient and case temperatures. Maximum voltage and current

in the gate circuit are sometimes specified.

Finally, temperature limits for storage and operation are given. The low-temperature

limit is dictated primarily by the differences in thermal expansion between the

chip and surrounding materials. The upper limit is set by considerations of damage

to the crystal substrate.

Typical SCR packages for International Rectifier Corp. units

which have current ratings from 50 to 100 amps.

When using the SCR as part of a circuit, the peak reverse and peak forward blocking

figures specified are the currents that flow at given sets of bias conditions when

the SCR is not conducting. These currents can be viewed as leakage and must be stated

for a given temperature or temperature range. An SCRs leakage is on the order of

0.1 percent of its forward current. Hence, an SCR rated at 100 amperes forward current

cannot be used to control a 50-mA load since the leakage current will be about the

same as the current being controlled.

The gate trigger voltage and current are specified for given anode-to-cathode

voltages and gate-to-cathode resistances. They are temperature-dependent and often

graphically plotted for SCR's not to trigger. The minimum values for firing at given

temperatures also appear on the plots. This information specifies the voltage and

current required for triggering the SCR, as well as the bias conditions to be maintained

in the blocking state.

The peak on voltage is the drop between the anode and cathode for a given load

current and temperature. It is generally in the range of 1 to 2 volts. The holding

current specifies the level to maintain to prevent the SCR from turning off.

The turn-on and turn-off times are stated for SCR's intended for high-speed switching.

The operating conditions must be specified if these parameters are to be useful.

Some fast SCR's have low-current switching times in tens of nanoseconds.

Design Considerations. Once the SCR is inserted between the

power source and the load, a means must he provided for triggering it. When used

to control ac, one of the simplest ways of triggering is to use the phase control

method. The negative alternation takes care of the turn-off. Then all that is necessary

to drive the SCR into conduction is application of a pulse to the gate when the

anode is positive with respect to the cathode. A phase control triggering scheme

in its simplest form is shown in Fig. 2. By choosing the appropriate resistance

and capacitance values for the network, the time, or phase, relationship of the

gate with respect to the anode-to-cathode voltage can be determined. Household lamp

dimmers often are designed this way and may employ two SCR's back-to-back to control

both ac alternations.

Because the phase between the gate and anode-to-cathode voltages determines the

time the SCR conducts, the average current through the SCR is dependent upon this

relationship. The firing angle can also be derived from an isolated source like

an error signal in a feedback system. When more current is needed, the error signal

"tells" the trigger circuit to advance the gate voltage to turn on the SCR earlier

in the cycle. This results in an increase in average current flow since the SCR

conducts for a longer period of time.

Fig. 2 - Schematic of a typical pulse triggering circuit

to turn on SCR. Waveforms below show voltages and current and indicate the firing

angle.

A transformer provides good isolation between the trigger circuit and the load.

The control signal might be a dc voltage, such as the on/off conditions of a switch

or logic circuit. A simple oscillator can be used to furnish the gate pulses, controlled

by a simple AND gate.

If moderate or high currents are to be controlled, the fast turn-on of the SCR

can generate high-frequency noise that will be radiated into space and passed along

ac power lines. These noise spikes may interfere with radio and TV reception and

cause malfunctions in interference-sensitive equipment. Filters can be used in the

power line to reduce this noise, but a different means exists for drastically reducing

or eliminating the noise.

If the time at which the anode voltage crosses through zero and begins its swing

toward positive (with respect to the cathode) can be sensed, a trigger pulse can

be provided at that instant. The SCR then starts conducting early in the positive

alternation and the current (in a resistive load) follows the sine wave of voltage

rather than suddenly jumping from leakage level to a high forward level (see Fig. 2).

Several manufacturers offer IC's designed specifically as zero-voltage detectors

to use in this application.

Applications. Apart from the familiar lamp dimmer switch and

speed controls for certain types of ac motors, the SCR is used in the home to provide

continuous (as opposed to stepped) control of heat in electric kitchen ranges. In

industry, the SCR is used to control power in battery chargers, power supplies,

and machine tools. Welders, power regulators, and temperature control systems have

been designed using the SCR as a power control element. Among the most popular of

automotive electronic ignition systems available is the SCR-fired system and its

variations. And new applications for the SCR are continuously being discovered.

Posted February 13, 2024

(updated from original

post on 10/19/2017)

|