|

May 1966 Electronics World

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Wirewound inductors (as most

are) can be mysterious entities even when you are familiar with their many interdependent

physical and electrical properties. Because of interwinding capacitance and a sometimes

(when a large number of turns are involved) rather significant series resistance,

the equivalent circuit model gets quite complex - literally in a mathematical sense.

If you have the luxury of staying far away from the self-resonant frequency (SRF)

of the coil, your component will behave very much like an ideal inductor, that is,

XL = 2πfL.

This 1966 Electronics World magazine article delves into what causes inductors

to act like parallel and/or series resonant tank circuits, how to avoid the inconvenience

of unwanted resonances, and how to exploit resonances in your favor. You'll also

learn (if you don't already know) the distinction between a "choke" and an inductor.

How to Select R.F. Chokes

Fig. 1 - Besides inductance, on RFC, like any other coil

has some distributed capacitance between turns and to chassis.

By Joseph Tartas

There is more to an r.f. choke than some wire wound about a form. When all its

characteristics are known, it can prove useful as a tuned circuit, transformer,

low-or high-pass filter, as well as an r.f. isolator.

Not so many years ago, the selection of an r.f. choke was not a difficult problem.

You simply asked for a Z-50, if you were working in the 50-MHz area, or a Z-14 if

your circuitry was in the 10- to 15-MHz range. Chances were, you didn't know anything

about the choke itself, other than taking the manufacturer's word that it was designed

to work in that range.

For very-low-frequency work, the selection of a choke usually depended more on

the inductive reactance and hence was usually some arbitrarily selected value of

high inductance. If you were really designing, you might make a lot of calculations

and measurements, throw in a few rules of thumb, and come up with the right value.

Today, the picture has changed considerably and instead of two or three makes

of chokes and a dozen or so values to select from, there are hundreds of sizes and

shapes as well as specific characteristics to meet extreme temperature, moisture,

or other environmental requirements. In a single manufacturer's line, there are

several physical sizes designed to fit requirements of current-carrying capabilities

and space limitations; and in cases of extremely small volume, there are non-insulated

chokes to reduce the physical size but retain the same electrical characteristics.

Fig. 2 - (A) How an RFC looks electrically. (B) and (C)

show "Q" and reactance, respectively, for different values of "Q."

The most important improvement in the RFC field in the past few years is the

information made available to the user through manufacturers' literature. This information

includes inductance; minimum "Q" (although often misleading-this will be discussed

farther on); approximate resonant frequency, perhaps the most important item; the

approximate distributed capacitance; the minimum parallel resistance at two widely

separated frequencies; the maximum d.c. resistance; the maximum current rating;

and in the case of one manufacturer, incremental current rating. Because of extreme

environmental requirements in military and industrial equipment these days, many

chokes are also rated for maximum temperatures ranging from 85° to 500°C

and power dissipations that depend upon body sizes, covering materials and core

materials.

In spite of all this information, it often requires a bit of reading between

the lines before you can make a sensible selection of the correct RFC to use in

your particular circuit. Before you can do this, however, you must have a thorough

understanding of the various characteristics and circuit requirements that go into

such a selection.

Why a Choke Is Used

Basically, an r.f. choke is nothing more than an inductance that, because of

its own distributed capacitance, forms a parallel-resonant circuit. This distributed

capacitance (Fig. 1) is a multiplicity of small capacitances existing between

adjacent turns and from anyone turn to all the others, as well as to a shield if

one is used, and to a ground if one exists in the vicinity of the choke when it

is installed in the equipment. For the moment, consider the self-capacitance, or

distributed capacitance itself (without the choke-to-ground capacitance), as being

in parallel with the pure inductance of the coil and having a resistance equivalent

to the resistive component of the choke. A choke would then appear schematically

as in Fig. 2A, and its impedance and reactance as in Figs. 2B and 2C, respectively.

As in all parallel-resonant circuits, the maximum impedance at resonance will

depend upon the "Q" and this, in turn, will be the deciding factor as to how effective

the choke will be at its self-resonant frequency and over how wide a frequency range

it will still be effective. The impedance depends upon the amount of self-capacitance

that exists in the choke and the equivalent parallel resistance. A good approximation

of the impedance of a parallel-resonant circuit is Zr = L/CR as long

as the circuit "Q" is at least 10. The value of R is normally the sum of the series

resistances of the inductance and capacitance, but in a choke the resistance involved

in the distributed capacitance is practically non-existent. This, then, boils down

to the inductance, the distributed capacitance, and the resistance of the winding

(d.c. + r.f. resistance as frequency goes higher) as affecting the over-all performance

of the choke; that is, the resonant impedance, the self-resonant frequency, the

"Q" and hence the bandwidth of the choke, and its effectiveness on the r.f. voltages

it is being used to suppress. Thus, it is obvious that the value of inductance of

a choke is not as important as the self-resonant frequency and impedance, although

the inductance does have some bearing on these factors.

Chokes come in many forms, the particular type depending upon the frequency involved,

the inductance necessary to achieve it, and the distributed capacitance that results

from the particular form factor and winding method. Many are simple single-layer

solenoids with or without powdered-iron cores; others are multi-layer coils of various

configurations; still others are single or multiple honeycomb windings with one

or more sections combined in series.

A single-layer solenoid has the lowest distributed capacitance, and this capacitance

is proportional to the diameter of the winding and to a smaller degree is affected

by the length and number of turns and, where only a few turns are involved, the

spacing between turns. For a single-layer, close-wound choke, the distributed capacitance

is approximated by Cd =.75 diameter (in inches), with C in pF.

Fig. 3 - Two different methods of winding multi-turn coils.

Note winding arrangement difference between (A) and (B).

Fig. 4 - Styles of coil construction. (A) Method of winding

a slot-wound coil. (B) A winding form as used for slot-wound coils. (C) Self-supporting

coil.

In a multi-layer coil (Fig. 3A), the capacitance is considerably greater,

not only because of the greater number of turns but also because of the relative

capacitances between layers and nearby turns. If the layers are wound so that the

difference of potential between any two adjacent turns is small, then the capacitance

is small; if the layers are wound in such a way as to have adjacent turns non-parallel

to each other, as in the honeycomb or universal winding, the capacitance is at a

minimum between those adjacent turns. The total distributed capacitance may be further

reduced by the use of powdered-iron or ferrite cores which reduce the number of

turns of wire necessary to obtain the desired inductance value. However, other problems

enter when cores are used, since the core losses, the capacitance effects due to

the dielectric material used in making the cores, and the useful temperature range

and effective permeability of the core which affect the "Q" must be considered,

as well as a factor that is often ignored in r.f. chokes, the temperature coefficient

of the core, which also affects the temperature coefficient of the choke.

In multi-section chokes, the individual sections may be alike or may be designed

so that the over-all choke appears as a broadband filter. In most cases, the choke

is not like a single resonant circuit but appears electrically as a multi-element

bandpass filter.

When a large inductance is required and the use of a single-layer coil is prohibitive

because of its size, the multi-layer coil becomes necessary. This, in turn, means

a larger distributed capacitance which is no longer directly related to the diameter

or coil size. One method of reducing capacitance is to wind the coil in such a way

that the high-numbered turns do not lie next to low-numbered turns (the condition

for greatest capacitance). Early attempts to reduce capacitance by means of "bank-winding"

(Fig. 3B) resulted in expensive chokes, since this method required great skill

by the winder and it could not be done by machine. The coil could not be held to

the production tolerances then required (and completely unusable with today's close-tolerance

requirements), and when large inductances were needed, the coil was so large physically

as to be almost impractical.

The development of the universal coil winder provided the designer with a new

and extremely useful tool that allowed him to repeatedly produce a mechanically

stable, relatively low capacitance coil with a fairly large inductance. This type

of winding, while not having the lowest attainable capacitance, was better than

a "happy medium" between the excessive capacitance of the layer-wound and the great

expense of the bank-wound coil.

The "universal" layer-wound coil, more commonly known as "pie-wound" because

of its resemblance to a pie, is a compromise between the bank-wound coil of Fig. 3B

and the slot-wound coil of Fig. 4A.

The slot-wound coil has a distributed capacitance equal to a two-plate capacitor,

each plate consisting of rings the width of the slot with one plate having the inner

coil diameter A (see Fig. 4B) and the other plate the outer diameter B. Since

a two-plate capacitor of two greatly different areas depends to a large extent on

the area of the smaller plate, the smaller the diameter of the inside ring (or the

winding form in this case) the smaller the distributed capacitance, and conversely,

the greater the inductance the pie will have for a given width and outer diameter.

The universal-wound pie of Fig. 4C is simply a free-standing, self-supporting,

slot-wound coil with a winding similar to the bank-wound coil, although restricted

because of the narrow cross-section of the slot.

As the art progressed, powdered-iron cores were developed, and their use as forms

or cores for universal-wound r.f. chokes allowed a great reduction in over-all size.

Like all new materials, powdered iron had its own limitations. If the permeability

(μ, the ratio of inductance with the core, to the inductance without the core)

was low, and the losses resulting from the insertion of the core in the coil (eddy

losses) were kept to a minimum (resulting in a reasonably high "Q"), the size of

the coil was not reduced greatly. Increasing the μ of the core material reduced

the choke size, but often it was found that the "Q" suffered greatly due to core

losses so that the series impedance (QX) was inadequate to warrant the use of a

costly and bulky component.

Eventually, new ferrite materials (ceramic materials with magnetic qualities)

were developed which allowed for great reduction in the size of an r.f. choke, but

as environmental temperature specifications for equipment were raised above the

usual 85°C, the temperature capabilities of the ferrites fell apart. Either

the temperature coefficient was poor, causing excessive change in effective inductance

with change in environmental temperature, or the permeability decreased so rapidly

above 85°C that the resulting inductance became too low to be effective long

before the maximum temperature requirements were met.

This led to further improvements in the capabilities of ferrite core materials,

and we now have extremely large inductances in very tiny packages with excellent

temperature and mechanical stability, and because of the extremely high permeability

of the cores, the distributed capacitance or "self-capacitance" of the choke remains

quite low.

Examples of this size reduction are a miniature 1000-μH choke with a molded

phenolic form having a distributed capacitance of 5 to 10 pF for several makes,

and a ferrite-bodied choke with the same effective inductance yet having less than

I-pF capacitance.

Chokes having an iron core, for the same inductance, run somewhere in between,

with a maximum capacitance of 7 pF.

In large chokes using non-miniature techniques, the capacitance is usually not

given, and often the self-resonant frequency is ignored as well. Because these chokes

are usually wound with larger wire to accommodate high currents, the capacitance

of these chokes would be even higher than that of the miniature types.

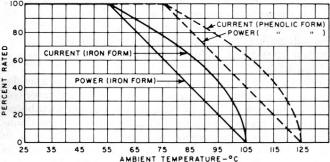

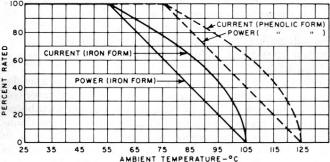

Fig. 5 - De-rating curve for one type of miniature r.f.

choke.

The current rating of a choke will often depend upon the ambient temperature

and will have to be derated. Fig. 5 shows a curve for de-rating one type of

miniature choke. If the current rating is given at the maximum temperature to be

encountered, then only the incremental current is of interest. This is the current

necessary to reduce the effective choke inductance by 5% due to the magnetization

of the iron core that effectively lowers the permeability and hence the inductance.

Chokes are normally used to prevent coupling of r.f. power (microwatts or megawatts)

from one circuit to another in a piece of equipment. Any wires that lead from stage

to stage, circuit to circuit, or from one sub-unit to another are potential conductors

of undesired r.f.

In r.f. circuitry in particular, there is usually a series of cascaded amplifier

or multiplier stages, and more often than not, an oscillator or two. Furthermore,

mixers, detectors, and other associated circuits are commonly involved in such circuitry,

and each is a source or terminus for leads that might conduct unwanted r.f. These

leads can be any or all of the following: "B+," "B-," a.g.c., filament leads, fixed

bias leads, leads to panel controls, and video or audio input and output.

Carefully selected, the proper choke can be an r.f, isolator; a shunt trap; a

tuned circuit either at its self-resonant frequency or, by means of additional shunt

capacitance, at some lower frequency; or can be combined with other components to

make a low-pass, high-pass, or bandpass filter.

A recently introduced innovation is a series-resonant trap that is in appearance

an r.f. choke. Utilizing the capacitance between turns as a series-coupling element,

it can be made in a wide range of series self-resonant frequencies. Like the parallel-resonant

choke, the series trap will probably find applications that formerly required an

external capacitor in conjunction with an RFC to make a series-resonant trap.

How to Use Chokes

Because a choke is composed largely of distributed inductance and capacitance

rather than lumped inductance and capacitance, it appears electrically as a transmission

line rather than as a tuned circuit. Depending upon the values of these constants

and the terminating impedance of this transmission line, a choke can act as an impedance

varying from extremely high to almost a perfect short.

At the fundamental (self-resonant) frequency and at all odd multiples of this

frequency, a choke appears as a parallel-resonant circuit. At even multiples, the

same choke acts as a series-resonant circuit with the lowest impedance limited only

by the series-resonant resistance, or essentially the resistance of the coil itself.

This phenomenon occurs because a choke does act as a transmission line and is not

terminated in its characteristic impedance. If it were so terminated, a choke would

be little more than a straight conductor or loss less transmission line for the

r.f. currents.

Because of the distributed elements, a choke may be thought of as a series circuit

composed of a number of elements, each element consisting of several small inductances

and capacitances in parallel; as two parallel branches, with one leg a series of

small coils and the other leg a series of small capacitors; or even as a combination

of the two, which would make it the equivalent of multi-element filter circuits.

Hence, at any given frequency, a choke can appear as almost anything from a high

parallel-resonant impedance to a very low series-resonant impedance.

It is customary, however, to select a choke having its highest parallel-resonant

impedance when it is to be used as an r.f. suppression element in a supply line

(in series with a "B+" line, for example), as shown in Fig. 6A. If a choke

is selected having the same self-resonant frequency (SRF) as the frequency it is

desired to suppress, then the choke must have the highest series impedance at that

frequency. And because a choke is a completely self-contained high-impedance element,

its SRF is not affected by external elements connected from either end to ground,

and further attenuation is achieved by bypassing either or both ends of the choke.

It is, however, affected by any parallel elements, and hence its SRF, "Q," or parallel-resonant

impedance can be lowered.

Fig. 6 - Various uses for r.f. chokes. (A) R.f. suppressor.

(B), (C), (D)Used as a tank coil. (E) Tuned circuit with tap. As a transformer,

an RFC can be used with (F) mutual, (G) top C, (H) top L, (I) bottom C, (J) bottom

L coupling.

Fig. 7 - (A) & (B) Coupling through a capacitor may

reduce effective coupling as one RFC may tune out other. (C) Coil separation produces

controllable coupling. (D) How RFC's are used in a typical high-pass filter unit.

Because it can be altered, such a choke may be utilized as a tank coil and tuned

by a fixed or variable capacitor connected across the choke (Figs. 6B, 6C, and 6D)

and have its loaded "Q" adjusted by adding a parallel resistor (or tube or transistor

circuit). Two chokes in series, with the combination shunted by a capacitor, provides

a tuned circuit with a tap (or an autotransformer), as shown in Fig. 6E. The

tap can be adjusted by the proper selection of the inductance ratio or impedance

ratio desired. Because of the extremely wide range of available chokes (0.10 μH

to many millihenrys) in small increments, almost any ratio is obtainable.

It is also possible to use two chokes as primary and secondary of a transformer

(Fig. 6F). Again, the wide range of values can be utilized for almost any transformation

ratio. Depending upon the size and type selected (magnetically shielded types would

not be suitable), the degree of coupling can be varied over a considerable range

by adjusting the relative separation between the two choke bodies. If greater coupling

is desired than can be obtained by mutual coupling, the usual methods of top C,

top L, bottom C, or bottom L, as shown in Figs. 6F through 6J, can be utilized.

However, because of the mutual inductance that exists between two chokes in close

proximity to each other, additional coupling through a physical capacitance may

actually reduce the effective coupling because one effectively tunes out the other

(Figs. 7A and 7B). To prevent this from occurring, sufficient separation to minimize

mutual coupling will give better control through the coupling elements, as indicated

by Fig. 7C.

It is just this capability of being coupled to a coil or another choke that often

requires that a choke be connected so that such coupling is at a minimum. Contrary

to the usual v.h.f. and u.h.f. wiring practices, it is often necessary to use maximum

lead lengths on chokes so that they may be placed away from tuned circuits or supply

lines containing similar or different chokes. And because of the peculiarities of

the distributed constants that make the choke what it is, the extra lead length

has little effect on its performance. Furthermore, placing a choke near the chassis,

although increasing the effective distributed capacitance somewhat, will provide

a certain degree of shielding.

If the choke is magnetically shielded, so much the better, for such a choke will

not only have little or no coupling to circuits but will also not radiate any r.f.

to surrounding circuits as is possible with unshielded chokes. However, a note of

caution is necessary. If a magnetically shielded coil is placed too close to a tuned

circuit, it can effectively load, or lower, the "Q" of that circuit considerably

because the closed ferrite body of the choke acts as if a shorted turn were coupled

to it.

As a series element, a choke may also be used as a trap, either at its SRF or

at some other frequency, by tuning it as a parallel circuit with additional capacitance.

As such, it may be coupled to a circuit either magnetically or capacitively. As

a series-tuned trap, the tuning capacitance should be large relative to the distributed

capacitance of the choke so that the effect of the distributed capacitance is minimized.

If the choke inductance is small, its effective inductance may be adjusted by the

length of its leads, as much as 10%.

Chokes may also be used, because of the small physical sizes and wide range of

inductances available, in the construction of miniature filters. A typical high-pass

filter is shown in Fig. 7D. In a majority of cases, the capacitance required

is large, the inductance values small, and the mutual coupling must be at a minimum.

Magnetically shielded microminiature chokes, combined with miniature ceramic capacitors,

can produce a high-pass, low-pass, or bandpass filter of incredibly small size yet

with extremely sharp bandpass characteristics and large off-frequency attenuations.

Reliability

R.f. chokes, like all other components, must be selected with a bit of wisdom

and a lot of understanding. In general, most standard makes of chokes will give

satisfactory results even beyond their rated capabilities, although this is not

a recommendation to use them in that way.

As long as chokes are operated within their intended ratings, and their specifications

and intended applications are considered wisely, there should be no problems either

in experimental use or in production.

Recent impartial tests indicate that potted, cement-coated, or otherwise encapsulated

coils tend to have a higher rate of failure as wire diameter is decreased.

Encapsulation tends to restrict the thermal expansion of the windings due to

the different expansion rate of the encapsulating material. These tests indicate

that such a restriction causes the wires to bite through the insulating coating

and short adjacent turns together. However, these tests also show that the failure

rate only increases rapidly above #34 AWG and at temperatures in excess of 150°C.

Furthermore, most encapsulated chokes use materials that do not hinder expansion

of the windings since the materials are, to a wide degree, either compatible in

expansion coefficients or are thermosetting and tend to soften slightly with elevated

heat.

How to Measure

Any of several instruments may be used to determine the various characteristics

of r.f. chokes. The necessity for doing so, however, will depend upon what kind

of information is made available by the manufacturer and just what interpretation

can be made of this information.

The approximate SRF (self-resonant frequency) may be found quite simply with

a grid-dip oscillator, provided the choke is not completely magnetically shielded.

If more than one dip is observed, the lowest frequency indicated will be the fundamental

SRF. With this set-up, you can then alter this frequency with additional shunt capacitance,

meanwhile monitoring the change until the desired frequency has been reached.

Table 1 - Self-resonant frequency is higher than test frequency.

Table 2 - The relationship between choke and "Q" meter tuning.

For any type of choke, shielded or not, a "Q" meter can be used to determine

the SRF and, simultaneously, the distributed capacitance and the "Q" at the SRF.

This last point is often overlooked in the application of a choke and the use of

the available data. A careless reading will lead the user to believe that the "Q"

shown is at the SRF, when it is actually the "Q" that is obtained at the frequency

of measurement at which the inductance measurement is made on the "Q" meter. Only

at the given test frequency does the "Inductance" dial read correctly, but the test

frequencies for the various inductance ranges differ from the SRF by a factor of

2 to 20 in the normal range of miniature choke values. The differences for one make

of choke are shown in Table 1. It is obvious from this table and from the vast differences

in "Q" for the same coil at various frequencies that one measurement cannot substitute

for the other. Of course, the "Q" may not be important in many applications, but

where it plays a significant part, it must be determined for the SRF or the frequency

at which it is to be used.

The SRF is measured on the "Q" meter by the following procedure. Connect the

test leads to the "Cap" terminals. With the choke disconnected and the leads in

place, connect to the "Coil" terminals a relatively high "Q" work coil that will

resonate in the region of the expected SRF of the choke. The choke is then connected

to the test leads on the "Cap" terminals and the "Capacitance" dial is tuned to

re-resonate the combination. If no change is necessary, then that frequency is the

SRF of the choke. If the "Capacitance" dial must be shifted to re-resonate, then

the entire procedure must be repeated, but at a higher or lower frequency until

the SRF is found. As a guide, Table 2 shows the relationships among the various

indications.

The effective parallel resistance Rp and effective parallel reactance

Xp at any frequency may be found by a similar method, except that the

process used to pinpoint the SRF is not necessary.

Adjust the "Q" meter for resonance at the test frequency F and record the indicated

"Q" as Q1 and capacitance as C1. Remove the test leads from the "Cap" terminals

and record the increase in capacitance needed to re-resonate the "Q" meter as C2.

Reconnect the leads and the choke to be measured, and re-resonate at F. Call the

new reading Q2.

The effective parallel resistance is found from Rp = [(1.59 x 105)

(Q1Q2)] / [f (C1 + CL) (Q1 - Q2)] and the effective parallel reactance is found

from Xp = (1.5 x 105) / f (C2 - C1) where f is in MHz and

C is in pF. The impedance is  at any frequency, and

Z = Rp at the SRF since Xp = 0 and at any frequency, and

Z = Rp at the SRF since Xp = 0 and  . .

Under some conditions (C2 - C1) may be negative, indicating a capacitive reactance

for the choke at that frequency.

The "Q" is found from "Q" = [ (C2 - C1) (Q1Q2)] / [C1 (Q1-Q2)] and is the "Q"

of the unknown impedance, or in this case the choke being tested. This is obtained

from the relation "Q" = Rp/Xp.

The distributed capacitance may be measured with the "Q" meter by the two-measurement

method when the distributed capacitance, Cd, is 10 pF or less, as follows.

Connect the choke to the "Coil" terminals and resonate the choke by varying the

"Frequency" dial, with the capacitance set at a low value (30 to 50 pF). Note the

frequency and call this capacitance C1. Change the frequency setting to one-half

the previous frequency setting and re-resonate the coil by varying the "Capacitance"

dial. The new value is called C2. The distributed capacitance, within 20%, is found

by Cd = (C2-4C1) /3.

A much simpler method of determining the approximate value of Cd is

from a resonance chart, where frequency, inductance, and capacitance are shown.

As long as Cd is small, it has a negligible effect on all but very small

values of inductance. For this reason, the apparent inductance will be close to

the true inductance, and the chart would probably show the required capacitance

to resonate the apparent inductance with as good an accuracy as the "Q" meter.

For example, a 10-μH ±10% choke measured by the above method had an apparent

inductance of 10.7 μH and a distributed capacitance of 0.67 pF. The "Q" at SRF

was not measured because the SRF was above the range of the "Q" meter.

From a resonance chart, the apparent inductance given in the manufacturer's data

sheet gives a capacitance value slightly higher.

The actual inductance that would be measured if the choke had no distributed

capacitance at all is found from the value obtained in the Cd measurement.

The true inductance is LT = LA [1[C1 / (C1 + Cd)].

In the case of the 10-μH choke just mentioned, LT = 10.7 [38/(38+.67)]

= 9.83 μH where C1 is the capacitance required to measure the apparent

inductance, 38 pF in this case; and LA is the apparent inductance.

Thus, the SRF can be determined from the values of LT and Cd,

or the approximate Cd can be obtained from the approximate SRF and a

resonance chart. Because of the nature of r.f. chokes and their various circuit

requirements, these approximations will quite often be adequate.

|

at any frequency, and

Z = Rp at the SRF since Xp = 0 and

at any frequency, and

Z = Rp at the SRF since Xp = 0 and  .

.