|

July 1965 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

If you like pronouncing long,

complex chemical names, you'll really enjoy this "Plastic Film Capacitors" article

from a 1967 issue of Electronics World magazine. It was written by Walter

Lamphier of Sprague Electric,

a long-time manufacturer of capacitors of all sorts. As of 1992, Vishay has owned

Sprague (founded in 1926 by Robert Sprague), but has strategically retained the

very familiar Sprague name as part of theirs. Anyway, a lot of information is provided

about the relatively new (at the time) plastic-film construction. A contemporary

article on the same subject would no doubt include a whole host of new chemical

compounds not even invented in 1967. This particular issue of Electronics World

reports on a few other kinds of capacitor constructions popular at the time, including

paper, ceramic, glass, and electrolytic.

Plastic-Film Capacitors

Fig. 1 - Internal details of a metal-encased film capacitor.

By Walter C. Lamphier / Senior Product Specialist, Sprague Electric Co.

Advances in plastic chemistry have produced an open-ended list of capacitor dielectrics

whose electrical characteristics can be tailored to suit almost any particular circuit

need.

Among the plastic-film dielectrics presently used in capacitors are polystyrene,

polypropylene, polytetrafluoroethylene,

polyester, polycarbonate. cellulose tri-acetate,

polypyromellitimide, and

polyparaxylene. The basic construction of capacitors using these materials is

quite similar. They may be considered as parallel-plate capacitors which have been

rolled into a coil. For the most part, the conducting plates extend from opposite

ends of the coil and have leads attached. The capacitor roll is protected from the

external environment by a metal case, a plastic housing, or a plastic encapsulation.

Fig. 1 shows the basic construction of a typical capacitor which might use any of

the these dielectrics.

The photograph (next page) shows a number of capacitors which demonstrate the

numerous variety of external housings and terminal arrangements in which plastic-film

dielectric capacitors are furnished.

The dielectric materials mentioned may be used to produce extremely thin sheets

which are employed as the separators in plastic-film capacitors. Each material is

used in capacitors because some particular characteristic or combination of characteristics

of the resulting capacitors is unique and most advantageous for specific circuit

applications. Table 1 covers some of the more important physical and electrical

properties of these materials.

Table I - Characteristics of the various dielectrics which are

used in the manufacture of plastic capacitors.

Some of the different methods of packaging plastic-film units.

Fig. 2 - Capacitance change vs. temperature for various plastics.

Fig. 3 - Dissipation factor vs. temperature for various plastics.

Polystyrene

Polystyrene is a polymer of the aromatic styrene monomer and possesses outstanding

electrical characteristics. Using this material, capacitors may be made to capacitive

tolerances as close as 0.1 %. They will retain this precise value almost indefinitely,

even following moderate temperature changes. The high resistivity and small negative,

but linear, temperature coefficient of capacitance make them very useful in analog

computers. The two chief limitations to the use of polystyrene capacitors are the

85°C maximum operating temperature and their relatively large size.

Polypropylene

Polypropylene is an aliphatic polymer of the propylene monomer and possesses

outstanding electrical characteristics similar to polystyrene. It is available from

high-volume production equipment and hence has the lowest price per pound of any

of the organic materials mentioned. Unfortunately, it has some serious limitations

because of its physical properties. It has low tensile strength and thus is limited

to a minimum thickness of 1.0 mil (0.001") at the present time. Its lack of physical

stability prevents it from having the outstanding electrical stability that is characteristic

of properly made polystyrene capacitors.

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is an aliphatic polymer of the fluorinated carbon

atom. Its intrinsic insulating properties are the best of ail plastic materials

presently used. The highly symmetrical fluorinated carbon atom, as well as a lack

of impurities in the material as manufactured. result in the highest resistivity

and lowest loss factor of all organic dielectric materials used in capacitors. It

also has a small linear negative temperature coefficient of capacitance. PTFE does

not melt but may be sintered above 300°C, indicating high bond strength which may

be capitalized upon to produce capacitors rated for reliable operation at 200°C.

The two most striking drawbacks of TFE-fluorocarbon capacitors are their large size

and high cost. The size is greater than that of polystyrene capacitors and the cost

is five times as great. Because of these limitations, PTFE capacitors are used as

a last resort when the highest insulation resistance possible, a linear temperature

coefficient above 85°C, or an operating temperature above 150°C are key

parameters. The material is available from several sources here and abroad under

such names as Teflon-TFE, Fluon, Halon, and other trademarks. It also has widespread

uses in such applications as coating for chemical ware and cooking utensils because

it is inert to most chemicals and materials do not adhere to it.

Polyester

Polyester capacitors are presently the most widely used of all plastic-film capacitors.

The most common polyester which is employed is a product of the reaction of

terephthalic acid

and ethylene glycol. The latter may be familiar as the standard non-boiling automotive

antifreeze material. Polyethylene terephthalate was originally developed abroad

and its electrical characteristics were first published in 1949. It is not only

used as a capacitor dielectric but it is also one of the most widely used synthetic

materials for making fibers for weaving cloth. Imperial Chemical Industries, which

originated PETP (to use the common abbreviation), markets its capacitor film under

the trademark Melinex and its fiber as Terylene. E. I. DuPont de Nemours, which

introduced the material into the U. S., calls it Mylar or Dacron for the corresponding

applications. A heavier gauge film for photographic purposes is sold under the trademark

Cronar by Dupont. Other vendors have recently come on the market with PETP as well,

selling it simply as an XX-brand polyester or under other trademarks, such as Celanar,

etc. A somewhat similar polyester material with slightly different qualities,

polycyclohexylene dimethylene terephthalate (abbreviated as PCHMTP or PMPT),

is sold by Eastman Kodak under the trademark Kodar.

Polyester, as made by Dupont, was the first dielectric to effectively challenge

the use of kraft paper in an important segment of the capacitor field. The material

is physically very tough. Moreover, it may be obtained in near-perfect sheets as

thin as 0.15 mil (15 gauge), 1/20 the thickness of a typical brunette hair. It exhibits

a much greater tolerance toward atmospheric contamination, such as from moisture,

than does kraft paper. For this reason, non-hermetically sealed polyester-film capacitors

have substantially replaced the conventional "paper tubular." Polyester capacitors

must be operated below the corona, or flash-over voltage of air, since voids are

always present. As a consequence, alternating voltages above 250 volts r.m.s. and

direct voltages above 2500 volts are frequently detrimental to dry-wound polyester

capacitors. A further limitation in PETP film is the second-order transition in

the material which may occur between 85° and 125°C. Indications are a substantial

increase in capacitance, a peak in the loss factor, and a pronounced increase in

failure rate cinder d.c. operation.

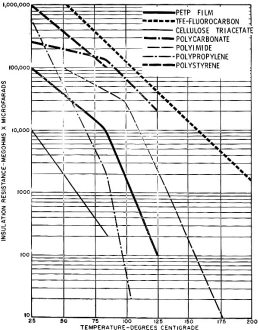

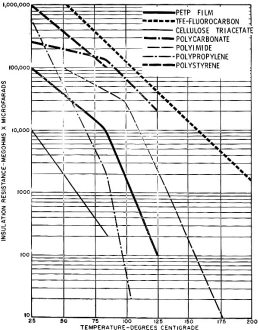

Fig. 4 - Insulation resistance vs. temperature for the plastics.

A combination dual dielectric of polyester film and kraft paper with various

impregnants, either "solid" or liquid, overcomes some of these problems and increases

reliability. These dual dielectric capacitors are very widely employed.

Polycarbonate

Polycarbonate, while also a polyester, is usually referred to by this generic

name. It is formed by reacting bisphenol-A and phosgene. The latter may be remembered

as a poisonous gas used in World War I.

The KG-polycarbonate material offered by the German firm Farbenfabriken Bayer

A. G. has proven to be superior to polycarbonates from other sources when used as

a capacitor dielectric. The thickness gauges are approximately the same as those

of Mylar-brand PETP. Its handling properties are quite similar; however, polycarbonate

does not exhibit the second-order transition characteristic of PETP and retains

its excellent electrical qualities at temperatures as high as 140°C. Both the

resistivity and loss factor approach the values for polystyrene. The capacitance

of polycarbonate units will change about 1% from room temperature over the operating

temperature range. The curve or capacitance change with temperature is crescent-shaped

with its maximum at about room temperature . Capacitance stability with time is

very good but not quite as excellent as that exhibited by polystyrene capacitors.

At this time, the two factors that have prevented its use in a major section of

the capacitor field are the physical condition of the sheet and the cost of the

film, which is more expensive than either paper of PETP-polyester.

It should be noted that dual-dielectric capacitors, which balance the characteristics

of PETP and polystyrene to achieve an essentially zero temperature coefficient of

capacitance over a wide temperature range, in many cases may be replaced by polycarbonate

units.

Cellulose Tri-Acetate

Cellulose tri-acetate (CTA), which is a nearly completely acetylated cellulose,

has been well known for many years. Straight cellulose acetate and cellulose acetate

butyrate have also been used as capacitor dielectrics but have been substantially

replaced by polyester. Cellulose tri-acetate, however, may be manufactured in film

as thin as 4 gauge or 0.00004". The smallest capacitor which can be manufactured

from CTA film is 1/3 the volume of the smallest equivalent PETP capacitor. Electrical

properties of the cellulose tri-acetate capacitors are adequate for most requirements

at temperatures up to 85°C but are a limitation on their use at higher temperatures.

Polypyromellitimide

Polypyromellitimide film is made from a resin resulting from the condensation

reaction of pyromellitic dianhydride and an aromatic diamine. This unique organic

polymer, sold by DuPont under the trademark Kapton-H polyimide, is capable of being

used over a very wide temperature range and is highly stable. Its electrical characteristics

approach those of TFE-fluorocarbon except that the temperature coefficient of capacitance

is positive and not precisely linear. The material presents a number of exciting

possibilities to the capacitor designer and user; but its ultimate value will best

be determined after some history in capacitor production when it has passed the

pilot-plant stage, production problems have been solved, and prices have been firmed.

This should not be too far in the future.

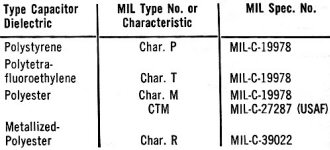

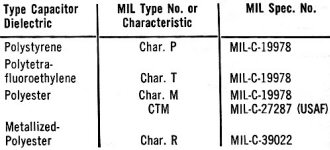

Table 2 - MIL-Specs covering some of the plastic dielectrics.

Polyparaxylene

Polyparaxylene polymer may be deposited on electrode in extremely thin films.

It is consistent with the other highly priced plastics mentioned previously in yielding

a dielectric strength of several thousand volts per mil. Capacitor data to this

time is quite limited because the material is still in the final stages of development

for this application. Available information does hold out the prospect of a substantial

reduction in capacitor sizes for uses above 125°C.

Because this film can be vapor deposited directly onto the metal electrodes as

a pure uniform polymer in thicknesses one-third that of free film dielectrics, stable

devices having less than one-fifth the size of polystyrene capacitors of equivalent

electrical rating can be produced.

Comparisons

Capacitors produced from these materials are compared in a number of ways when

selecting the proper type to best meet circuit needs. The curves given in Figs.

2, 3, and 4, showing variation in capacitance, dissipation factor, and insulation

resistance to temperature, illustrate the type of data used for this purpose.

In addition to these fundamentals, two other features of organic-film capacitors

must be taken into consideration. Of the eight materials mentioned, polystyrene

has not been extensively available or used in the metallized form. Thin sheets of

polystyrene must have very low voltage ratings, and the basic size problem which

exists with capacitors made from this material becomes amplified. Both TFE-fluorocarbon

and polyparaxylene can be deposited on electrodes by vacuum techniques which permit

film thicknesses of less than 1000 Angstrom units. These techniques are still in

the embryonic stages but do present the possibility of low-voltage film capacitors

in the future being minified to approach the sizes, in some cases, of aluminum electrolytic

capacitors. As previously mentioned, two different films may be used together in

a capacitor winding, either in series or in parallel within the same roll. The resultant

compromise in electrical characteristics can be forecast from curves of Figs. 2,

3, and 4. The PS/PETP combination, which has substantially zero capacitance change

from 0°C to 80°C, is the best in this respect of any known capacitor, including

the so-called NPO ceramics.

MIL Spec

One measure of the acceptance of a new type of capacitor in industry is found

in the status of its Military Specification. MIL Specs are written only after a

capacitor has had some usage by suppliers of military electronic equipment. A rule

of thumb might be that a MIL Spec is generated after two to three years of significant

and successful usage. Keeping this in mind, Table 2 may be of interest, setting

forth as it does the present specification status in the Department of Defense of

capacitors which are currently manufactured from the organic plastic materials discussed

in this article.

Posted September 7, 2022

|