|

October 1959 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Germanium was "the"

semiconductor of choice in 1959 while advances were being made with silicon.

Most of the newer semiconductor devices were being fabricated with germanium as the

central transducer element. Temperature sensors, strain gauges, "sensistor" variable

resistance units, Hall effect sensors and gyrators and circulators, torsional (twist)

transducers, displacement sensors, and even neutron detectors were done in germanium.

Even though silicon is referenced as being applicable to all the devices, it was not

until the 1960s that silicon began to dominate semiconductor fabrication. This paper titled ,"From Germanium

to Silicon, A History of Change in the Technology of the Semiconductors," by

Philip Seidenberg,

does a nice job summarizing the transition period.

Novel Semiconductor Devices

Some interesting new and unusual semiconductor products along with a few of their

applications.

The usefulness of semiconductor materials, such as silicon and germanium, in the field

of transistors and diodes is well established. It might be reasoned that materials of

such wide usefulness in one area could also find applications in other areas and we find

this to be the case. Some of the properties of semiconductor materials, such as extreme

stability, temperature sensitivity, and sensitivity to magnetic fields, have been exploited

and several devices are now under active development in various laboratories.

Fig. 1 - Germanium resistance thermometer as it appears with the outer

case removed.

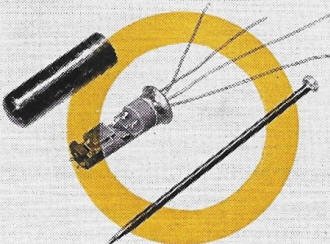

Fig. 2 - Pair of probe "Sensistors."

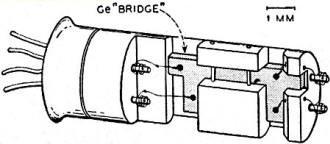

Fig. 3 - Cross-section drawing showing construction of germanium resistance

unit.

Fig. 4 - Germanium resistance thermometer compared in size with common

pin.

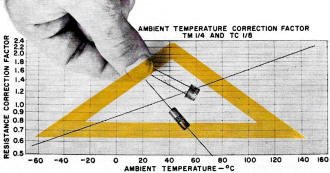

Fig. 5 - Ambient temperature correction factor curves for the "Sensistors"

shown. The factor from this curve multiplied by the resistance at a temperature of 25°C

will give the no-load resistance of the units at the desired ambient temperature.

Fig. 6 - A photograph of the Halltron HS-51 unit. Refer to text for

details.

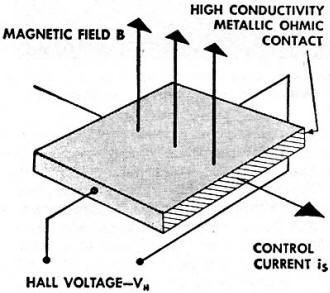

Fig. 7 - Semiconductor Hall Effect voltage generation is illustrated

here.

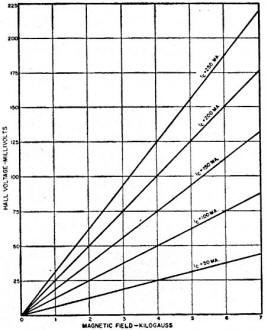

Fig. 8 - Hall voltages for typical Hall generator for various values

of control current and for various magnetic fields.

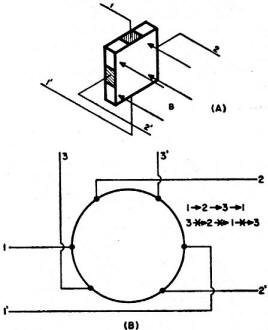

Fig. 9 - Basic diagram of (A) Hall Effect gyrator and (B) Hall Effect

circulator.

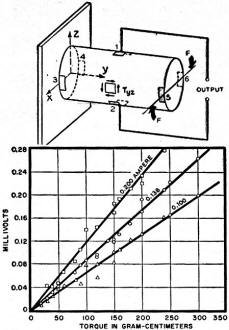

Fig. 10 - The torsional transducer. Graph shows calibrations at various

bias currents.

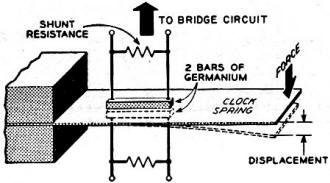

Fig. 11 - Displacement gauge constructed with germanium crystals.

Such gauges are up to two orders of magnitude more sensitive than common types that may

be used.

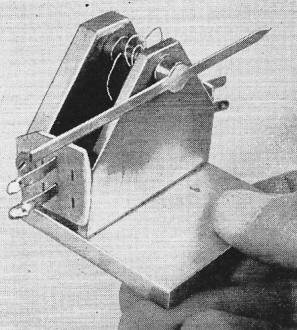

Fig. 12 - Shown above is a photograph of the torsional transducer

described in text.

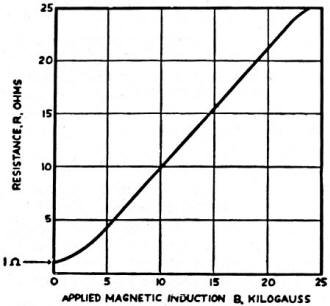

Fig. 13 - Resistance of typical MS-41 Magnetoresistor for various

magnetic fields.

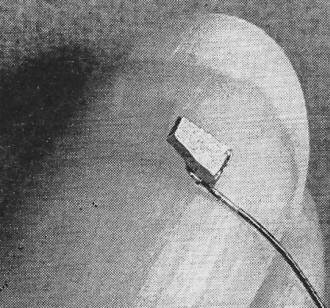

Fig. 14 - Neutron detector formed by a thin slice of germanium coated with uranium

layer.

Temperature-Sensitive Resistor

Single-crystal silicon has a very high positive temperature coefficient, that is,

its resistance increases very rapidly as its temperature rises. This characteristic has

been applied by Texas Instruments, Inc. in developing a device which has been trade named

the "Sensistor." This device has a positive temperature coefficient of resistance of

0.7% per degree C., which means that the resistance increases 0.7% for every degree the

temperature rises.

"Sensistors" are available with 1/4-watt and 1/8-watt ratings and a wide variety of

resistances. For the sake of comparison and uniformity, the resistance is usually given

at 25° C, which is normal room temperature. The actual resistance at any other temperature

can then be computed from a chart similar to Fig. 5, which gives the resistance at a

given temperature in terms of the value at 25°C multiplied by an appropriate factor.

As an example, suppose we have a nominal 100-ohm "Sensistor" and would like to know

its resistance at 50°C. Looking at the 50° point on the chart, we find that the multiplying

factor is about 1.18. Therefore, the resistance will be 100 x 1.18 or 118 ohms. Similarly,

we can compute the resistance value at any other temperature.

We can also compute the resistance by using the temperature coefficient and not referring

to Fig. 5 at all. In the example just given, the temperature increase (from 25°C

to 50°C) is 25°. Multiplying this by the temperature coefficient, 0.7% (0.007),

gives an increase of 0.18 ohm for every ohm of initial resistance. Since the initial

resistance was 100 ohms, the new resistance will be (100 x 0.18) or 18 ohms higher than

at room temperature.

It can be seen from these properties that the "Sensistor" can be employed as a sensitive

thermometer when used with an ohmmeter. A new scale for the ohmmeter can be calculated

without the laborious process of calibrating it. Care must be taken in applications of

this kind, however, to make certain that the measuring current flowing through the "Sensistor"

is not sufficient to alter its temperature due to this I2R loss.

For probing into very small spaces where temperature indications are desired, Texas

Instruments has developed a glass-encased probe "Sensistor." Its temperature-resistance

characteristics are very similar to the straight "Sensistor," but its mechanical construction

is quite different. It is made in the form of a cylinder about half an inch long and

less than one-tenth of an inch in diameter. See Fig. 2.

Many applications for the "Sensistor" are apparent, other than its possible use as

a thermometer. For example, it can be used to compensate for temperature changes in devices

having a negative temperature coefficient. It can also be employed in telemetering applications

where it is desired to transmit information on temperature back to a base location. Other

applications include amplifiers, power supplies, servos, and computers.

Low-Temperature Thermometer

Along somewhat similar lines, but operating in a completely different temperature

range, is the germanium low-resistance thermometer (Fig. 1) developed at Bell Telephone

Laboratories. Although not on the market as yet, this device is undergoing tests and

undoubtedly will be made by some interested company in the near future.

Extensive work is now being carried out in the field of cryogenics, that is, low-temperature

research. Temperatures involved may be in the neighborhood of the boiling point of helium,

4.2° Kelvin (4.2°C above absolute zero) and may range downward to within a fraction

of a degree of absolute zero or upwards to around 500K or so. Temperature-indicating

devices normally employed to cover this range are, in some cases, bulky and in other

cases require repeated recalibration, making them highly inconvenient to use.

The new thermometer, which is formed from a single crystal of n-type germanium, is

extremely stable and, once calibrated, holds its calibration very closely even though

repeatedly cycled from room temperature down close to absolute zero.

Fig. 3 shows the general construction of this device and the photograph of Fig. 4

indicates its size in comparison with a common pin. It is very small so as to be useful

in places where space is at a premium.

The active element is a bridge cut from a slice of germanium doped with arsenic to

make it n-type material. It also is a resistance thermometer, meaning that temperature

is indicated by measuring the resistance of the germanium slice. This is done by passing

a very tiny current through the slice and then measuring the voltage drop across it.

The actual resistance can then be computed from Ohm's Law:

R = E/I.

These thermometers have extremely high sensitivity, their resistance changing rapidly

with variations in temperature. For example, one unit tested had a resistance of 0.015

ohm at room temperature, 14 ohms at 10°K, and 216 ohms at 2°K. Both the temperature

coefficient and the actual resistance vary widely with minute changes in the amount of

doping, making it possible to construct thermometers having any of a wide range of characteristics.

It appears that the germanium resistance thermometer will have wide application -

from precise laboratory measurement of low-temperatures for cryogenic and calorimetric

work to sensing temperatures in outer space.

Strain Gauges

There is another property of semiconductor materials which is in the early stages

of exploitation by many laboratories but apparently no commercial devices are yet available.

This property is called piezoresistance-extreme sensitivity of the resistance of such

materials to tiny stresses and strains. Such a property makes these materials potentially

valuable as very sensitive strain gauges.

A strain gauge is normally made of wire. It is cemented to a beam, shaft, or other

device and will indicate very small bends or twists by a change of resistance. This resistance

change, in general, is quite small, requiring rather sensitive instruments if extremely

small motions are to be detected with any reliability.

By using a section from a single crystal of semiconductor material, sensitivities

of 10 or even 100 times as great as with conventional wire gauges appear possible. This

opens up a whole new field of application for germanium, silicon, and other semiconductor

materials.

These materials have other advantages over conventional gauges-they are stable over

a wide range of temperatures and respond accurately both to static strains and to varying

strains at frequencies up to the resonant frequency of the material employed.

Germanium appears to be useful up to 600°K., silicon to 1000°K., and the new

intermetallic semiconductor gallium arsenide may extend the temperature range up to around

1400°K.

Semiconductor strain gauges may be designed to measure either displacement, as shown

in Fig. 11, or torque, as indicated in Figs. 10 and 12. In the latter case, a cylinder

cut from germanium is cemented to the torque member and six leads attached. When provided

with appropriate biasing currents, a direct-reading sensitive torque meter results.

Pressure gauges made of semiconductor materials are extremely simple and reliable.

The materials are sensitive to pressure, that is, their resistance changes as the pressure

changes. Because of their stability and small size, such gauges can be immersed in many

different liquids and gases, and pressures measured by bringing two leads out of the

container.

Another desirable property is mechanical strength. In general, semiconductor materials

are relatively rugged and will withstand fair amounts of bending and twisting without

becoming permanently deformed.

The Hall Effect

From our basic electricity we remember that if a wire is carrying current while it

is in a magnetic field, there will be a force acting on the wire. This is the basic operating

principle of electric motors. If we were to explore the situation more fully, we would

find that the force actually acts on the free electrons which are carrying the current

in the wire and not on the wire itself. The net effect is the same, though, since the

electrons are confined in the wire. Any sideways force on the electrons is transferred

to the wire.

Because of this force, the electrons in the wire are pushed over to one side, leading

to an excess of electrons on that side and on the other side a deficiency. We might then

expect that a voltage would exist between the sides of the wire. This is exactly what

does happen, except that in good conductors the voltage is very small and hard to detect.

This is known as the "Hall Effect" and the voltage is called the "Hall Effect voltage."

The Hall Effect is a very useful tool in studying semiconductors, because in such

materials the effect is appreciable and the voltages produced can be measured readily.

In a semiconductor, the current may not consist entirely of a flow of electrons but may

also include the movement of "holes" or spaces where an electron is absent. As may be

expected, the magnitude of the Hall Effect depends on how easily these electrons and

"holes," usually called charge carriers, move around in the material. This property has

been termed "mobility." Greater mobility produces greater Hall Effect voltage.

Fig. 7 shows the results of the Hall Effect. Here we have a slice of semiconductor

material with current flowing through it. A magnetic field is perpendicular to the slice.

When these two conditions exist, a voltage will appear across the sides of the slice,

its magnitude proportional to the product of the magnetic field and the current. As a

typical example, if the current is 1/2 ampere and the field strength 10,000 gauss, the

voltage may be around 1/2 volt.

A commercial Hall Effect device is now on the market. It is manufactured by Ohio Semiconductors,

Inc. and is known as the "Halltron HS-51," which is shown in the photograph of Fig. 6.

The active part of this device is an intermetallic semiconductor known as indium antimonide,

a material which has a very high mobility - much higher, in fact, than silicon or germanium.

Many possible applications can be envisioned for the "Halltron HS-51" and similar

devices. The most obvious, perhaps, is the measurement of magnetic field strength. For

a constant current, the output voltage varies directly with the strength of the magnetic

field perpendicular to the slice of semiconductor material. Other possible applications

include a clip-on type ammeter, instantaneous power meter, d.c.-to-a.c. converter, and

perhaps in computers for analogue summation and multiplication.

Westinghouse has also announced the development of Hall generators using both indium

antimonide and indium arsenide. Voltages of 1/2 volt with a magnetic field strength of

5000 gauss and a control current of 1/2 ampere are obtainable with these devices. Fig.

8 shows the characteristics of a typical device. Output impedances can be adjusted from

0.01 to 20 ohms and their maximum frequency response ranges from 10 to 100 megacycles.

A study was made recently at Bell Telephone Laboratories of the many possible applications

of the Hall Effect. This study revealed that of the many possible uses two of the most

interesting are the gyrator and the circulator. These devices are sketched in Figs. 9A

and 9B.

The gyrator has probably received more attention than any other Hall Effect device.

By employing the gyrator in suitable circuitry, an isolator can be constructed in which

signals can be transmitted in one direction but not in the other. A germanium isolator

has been built with a forward loss of 14 db and a reverse loss of 75 db. Thus, the gyrator

could be used to isolate an antenna from a load, for example.

Fig. 9B shows what is known as a three-port circulator. In this device, signals can

pass from terminals 1-1' to 2-2', 2-2' to 3-3', and 3-3' to 1-1', but not in the other

direction, such as 2-2' to 1-1'. The circulator can be constructed from a slab of semiconductor

material with six equally-spaced edge contacts. Forward loss in a device of this kind

is about 17 db, and reverse loss in a typical n-type germanium slab may be as high as

64 db. A relatively high magnetic field is required with germanium, but a device of this

kind made of indium antimonide could operate satisfactorily with a relatively low field

of about 1000 gauss.

Because of the relatively high forward loss, Hall Effect devices of this kind must

normally employ a negative resistance amplifier for maximum usefulness. However, they

have the big advantage of theoretically being able to transmit d.c. signals as well as

a.c. signals at frequencies approaching the dielectric relaxation frequency of the semiconductor

material.

Other Hall Effect devices which have been explored, either experimentally or theoretically,

include a negative resistance amplifier, mechanical transducer, electrical compass, modulator,

and demodulator. These devices do not involve p-n junctions and so the surfaces do not

need elaborate protection.

Magnetoresistance

As mentioned before, when a slice of current-carrying semiconductor material is placed

in a magnetic field, the charge carriers are pushed over to the sides of the slice in

a direction perpendicular to the current flow. This has the effect of increasing the

resistance of the slice. Here, then, we have a device whose resistance can be altered

by changing the strength of the magnetic field in which it is placed.

This effect is known as "magnetoresistance."

Ohio Semiconductors, Inc. has developed a device utilizing this effect and has trade named

it the "Magnetoresistor." The type MS-41 utilizes a thin slice of indium antimonide,

again because of the high mobility of the charge carriers in this material. A resistance

change of as much as 1 to 10 can be obtained with a change in field strength from zero

to 10,000 gauss. The change in resistance is proportional to the square of the magnetic

field up to about 7000 gauss and is then directly proportional to field strength to over

20,000 gauss. A typical characteristic curve is shown in Fig. 13.

This device has many possible applications, including a contactless potentiometer,

modulator chopper, amplifier, and regulator. The MS-41 has a zero-field resistance of

one ohm, but units having values ranging from 0.01 to 50 ohms are being developed.

Neutron Detection

One of the most unusual applications of semiconductor materials was recently announced

by Westinghouse Electric Corp. Scientists at Westinghouse have developed a neutron detector

made of a tiny slice of germanium or silicon no larger than the head of a pin. The slice

is treated to form a p-n junction and a very thin layer of uranium is spread on the top

surface.

Slow-speed neutrons strike this uranium layer and cause U-235 atoms to split apart

just as they do in a nuclear reactor. The high energy products of this fission produce

an electrical pulse at the p-n junction, and so can be counted. Fast neutrons do not

produce fission and so are not counted, nor are gamma rays.

If desired, this neutron detector can be converted to count fast neutrons by replacing

the uranium layer with a material rich in hydrogen, such as paraffin.

Accurate mapping of both slow- and high-speed neutrons is a necessity in a nuclear

reactor. Because of its very small size, this detector can plot neutron flux variations

down to dimensional changes as small as one twenty-fifth of an inch. Thus, this neutron

detector can be a highly useful device wherever accurate neutron mapping is necessary.

The size of the detector is indicated in Fig. 14, where it is shown resting on a man's

thumbnail.

Conclusion

We have discussed here a few of the many possible applications of semiconductor materials,

based on phenomena which have been explored intensively. Which of these will find wide

usage is very hard to say at this time, but it is obvious that they are all of great

interest. They are all products of the intensive research into the properties of semiconductor

materials which was sparked by the invention of the transistor at Bell Telephone Laboratories

in 1948.

Posted July 4, 2018

|