|

Here is the "Electrician's Mate 3 - Navy Training Courses"

(NAVPERS 10548) in its entirety (or will be eventually). It should provide one of

the Internet's best resources for people seeking a basic electricity course - complete

with examples worked out. See

copyright.

See Table of Contents.

¶ U.S. GOVERNMENT PRINTING OFFICE;

1949

CHAPTER 15

SEARCHLIGHTS

NAVY TYPES

Navy searchlights are classified as to the size and source of light.

The 36-inch and 24-inch searchlights use high intensity carbon arcs

as the source of light, while the 12-inch searchlights use an incandescent

lamp, usually a 1,000-watt lamp. The size of these searchlights is determined

by the diameter of the parabolic reflector.

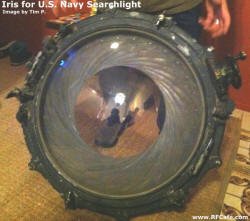

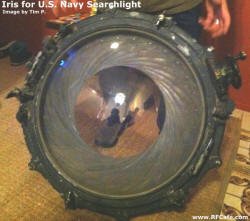

Iris Mechanism for 24" U.S. Navy Searchlight (photo by Tim P.)

"Kirt, I just found your website while looking for an explanation

of the purpose of a device that a friend of my owns. It is an iris

shutter for a 24" naval searchlight. Your site and description of

the searchlight helped to figure out the mystery of this thing!"

"I was at a friends party new years eve and he dragged the thing

out of a closet and started showing it off to those of us that were

interested. It weighs about 50 lbs. I would say, it is made out

of cast aluminum and the glass dome is surprisingly thin. Tempered

no doubt, and it says Bausch & Lomb right on the glass.

My friend bought it from an antique dealer."

USES OF SEARCHLIGHTS

The 36-inch light is used primarily for fire control. Usually they

are equipped with remote control systems so they can be trained and

elevated from the gun fire control director. Most are equipped with

an iris shutter and may be operated either manually or by an automatic

motor. The 24-inch searchlight is a general purpose light and although

it may be used for fire control purposes, generally it is used for long

range signaling. These searchlights are not equipped with remote control

for train and elevation. The light sometimes is equipped with the remote

control signal key. This lamp usually has both the iris and vane type

shutter.

The 12-inch searchlight is used primarily for short

range signaling. These lights are not equipped with remote control equipment,

and have a manually controlled vane type shutter.

REQUIREMENTS OF A SEARCHLIGHT

A Navy searchlight must have a narrow, pencil-like light beam. The

light must be non-flickering and of a 'bluish white color. It must operate

properly from any position, under all weather conditions, and give trouble-free

operation over a long period of time. The train and elevation characteristics

of most lights are: train through 360°, elevation of 110° to 120°, and

depression of 30° to 40°.

THEORY OF CARBON ARC SEARCHLIGHT

When an electric current at a moderate voltage is passed through

two carbon rods, considerable heat is developed at the point of contact.

Now if the carbon rods are separated a short distance a flaming arc

will be drawn out.

The act of making contact between the two

carbons is necessary to start the arc and is called STRIKING THE ARC.

When contact first occurs, a high current flows through the carbons.

The high current produces heat which vaporizes the soft center of the

positive carbon. This vapor acts as a conductor for the current as the

carbons are drawn apart and will keep the current flowing until the

distance between the carbons becomes too great. As the distance between

the carbons increases the resistance of the arc circuit increases.

The carbon vapor concentrates as a small ball in a depression in

the positive carbon. This depression is called the CRATER. This ball

of flaming gas in the crater is intensely luminous and is located at

the focus of the reflector. The reflector thus projects the light from

the arc crater into a beam of light, just as the reflector in your automobile

projects the light from the lamp filament into a light beam.

HIGH INTENSITY arcs work on the same principle as low intensity

types except that the current is increased and the diameter of the carbon

decreased, to obtain a more brilliant and concentrated source of light.

Figure 141. - The 24-in searchlight.

SEARCHLIGHT CONSTRUCTION

The high intensity arcs require ventilation systems at all time

to prevent overheating.

The arc and reflector are housed in the

DRUM, which is supported on TRUNNION ARMS so that it can be tilted,

to elevate or depress the beam. The BASE supports the trunnion arms

so they can rotate. The drum is thus mounted so the light beam can be

trained as well as elevated.

The power supply is brought up to

the light through slip rings and brushes inside the base, thus permitting

continual rotation in either direction. In some bases the power is brought

up by flexible cables. These cables must have a long loop left in order

to permit rotating the searchlight. This light can be only rotated one

and a half revolutions in either direction.

Trunnion

Arm. The trunnion arms support the main body of the searchlight.

The drum is mounted on ball bearings located at the tops of trunnion

arms, allowing for free elevation and depression of the lamp. A locking

device is on the trunnion arm to secure the light in elevation and depression.

The trunnion arm rides on ball bearings mounted on the top center

of the base, to allow rotation of the lamp in train. A locking device

is provided on the base for securing the light in train.

Drum. The drum is the main body of the searchlight and consists

of a barrel and access doors. The ventilating motor and shutter usually

are mounted on or in the drum.

Vent Motor. The ventilation

motor is located in a hood mounted either on the top or bottom of the

barrel. The motor is connected in parallel with the arc circuit so that

as soon as the lamp switch is closed the motor runs. Notice circuit

of wiring in figure 142.

Figure 142. - Wiring circuit for 24-inch

searchlight.

Arc Image Screen. The arc image screen is located near

the top of the barrel. It contains a lens system and a ground glass

screen. The screen gives the operator an indication of the condition

of the arc. A marker on the ground glass screen indicates the proper

position for the positive carbon. The arc image screen does not give

a direct view of the arc, only an image. Figure 143 shows the correct

and incorrect positioning of the carbons as viewed in the screen.

Figure 143. - Views of carbon position.

Arc Lamp. The lamp consists of the support and carbon feed

mechanisms as illustrated in figure 144. The COLUMN is the upright which

supports the two feed heads, and acts as a return for the negative side

of the arc current. The column is hollow and allows air to flow through

it to cool the positive head.

Figure 144. - Searchlight lamp mechanism.

Positive-head. The positive head is the mechanism which

supports, rotates, and feeds the positive carbon. These functions are

all automatic. The positive head has metal brushes to conduct the current

to the carbon.

Obdurator. The obdurate is the metal shield

on the positive head. It prevents the heat of the arc from reaching

the gear and other exposed mechanism of the positive head. It also helps

direct the light rays back to the reflector.

AUTOMATIC FUNCTIONS

The lamp has five automatic mechanisms. They are:

Forced draft ventilation.

Positive carbon feed.

Rotation of positive carbon.

Negative carbon feed.

Automatic arc striking.

FORCED DRAFT VENTILATION

The ventilation motor is usually a motor of approximately 1/12 horsepower

connected across the arc circuit. As soon as the lamp switch is closed

the vent motor is energized. In operation of the searchlight, the first

thing to check is the ventilation.

POSITIVE CARBON FEED

The ball of vapor is the main source of light and must be kept at

the focal point of the reflector. The focal point is the point where

all light rays from the ball of vapor will be reflected back in parallel

lines.

As the positive carbon burns back, the luminous ball of vapor

will move out of the focal point. Therefore, some means must be made

to keep the luminous ball of vapor at the focal point. This is accomplished

by feeding the positive carbon forward as fast as it burns away.

The positive feed system contains a thermostatic switch, a solenoid,

a lever and gear system. The power to rotate the positive head is furnished

by the feed motor. The feed motor is connected across the arc circuit

and runs when the lamp switch is closed.

The thermostatic switch

in figure 145 is made of two metal strips welded together. When heated,

one strip expands faster than the other and closes the circuit to the

positive mechanism. When the positive carbon is in the proper position

the heat rays from the arc vapor do not fall on the bimetallic strip.

The switch will then be open and cuts off the feed current. As the carbon

burns back the heat rays once more strike the bi-metallic strip, closing

the feed circuit and feeding the positive carbon forward.

Figure 145. - Thermostatic switch, positive

feed mechanism.

ROTATION POSITIVE HEAD

The positive carbon must be rotated all the time in order to keep

the crater that holds the ball of luminous gas symmetrical. The feed

motor is connected across the arc. circuit so that the motor runs all

the time the switch is closed. The positive head mechanism is geared

directly to the feed motor. The positive head rotates as long as the

light is in operation.

PEEP SIGHT

The peep sight is a small circular opening with a colored glass

window to give the operator a direct view of the arc.

REFLECTORS

The reflector is a parabolic mirror which collects the light rays

and reflects them in a parallel beam. Two types are in use, glass and

metallic.

Glass Reflector. The glass reflectors are

made of optical glass with the reflecting surface coated with silver.

It is efficient but has two disadvantages: first, breakage due to intense

heat in drum and due to shock; and secondly, the. silver peels. This

reflector should be cleaned only with alcohol and precipitated chalk.

Several metals such as chromium steel, coated aluminum and other

alloys are used in manufacturing the METALLIC REFLECTOR. They are not

subject to breakage or peeling. This reflector may be cleaned with bright

work polish or any polish not containing an abrasive. In cleaning NEVER

USE A CIRCULAR MOTION - always WIPE FROM the CENTER OUT.

SHUTTERS

Shutters are provided so the light beam may be secured without securing

the lamp. They are mounted in the front of the barrel and are of two

types - the VANE SHUTTER and IRIS SHUTTER.

The IRIS SHUTTER

is light proof. It can be operated manually or by a control motor. This

shutter is too slow to be used as a signal shutter. It should be cleaned

and lubricated according to manufacturer's instructions.

The

VANE type SHUTTER is used for signaling and is primarily a speed shutter.

May be operated by manual control or by an automatic key. This shutter

is not fully light proof.

RHEOSTAT

The rheostat has a low resistance and high current carrying capacity.

One of its most important functions is to prevent a direct short circuit

when the arc is first struck. It should be set for the proper operating

current of the searchlight, and after its initial setting, should not

require adjustment unless a change in the operating current is made.

CURRENT CONTROL NEGATIVE FEED

Feeding of the positive carbon is automatically controlled so that

the crater is always at the focus of the reflector. The negative carbon

feed is also automatically controlled, to keep the arc length constant.

Two types of automatic negative feed are used - CURRENT and VOLTAGE

types.

A CURRENT CONTROL negative feed system may be identified

by coil wound with heavy strip copper and connected in series with the

arc circuit. The current control feed system depends upon a varying

current through the arc to actuate the system. The equipment consists

of a current coil and plunger which regulate a motor drive for feeding

the negative electrode. One end of a pivot arm is attached to the plunger

and the other end of the arm is attached to a spring. The current coil

is in series in the negative side of the arc circuit.

When the

lamp switch is first closed, a very small current flows. This allows

the spring to overcome the pull of the current coil, and pull the lever

arm down so as to engage the high speed forward feed. The negative carbon

is fed forward until it makes contact with the positive carbon. When

the carbons strike, there is a high rush of current. This high current

cause the current coil to overcome the pull of the spring and engage

the reverse high speed feed, thus pulling the negative carbon back and

drawing out the arc. When the pull of the current coil and spring tension

are in balance the negative carbon will cease to feed.

Any change

in arc length after the arc is struck will be taken care of by the low

speed gears. The action of the current coil is the same as in the high

speed feed except the feed lever engages the low rather than the high

speed gears.

Figure 146. - Positive carbon feed drive

mechanism.

If the negative carbon were fed too far forward the arc current

would increase, causing the coil pull to overcome the pull of the spring

tension and engaging the slow speed reverse gears to feed the negative

carbon back until the arm balances.

In a current control negative

feed system INCREASING the SPRING TENSION will DECREASE the ARC LENGTH

and decrease of the spring tension will increase the arc length.

VOLTAGE CONTROL NEGATIVE FEED

In the VOLTAGE CONTROL negative feed system, the voltage drop across

the arc circuit operates the system. It consists of a voltage regulator

coil, plunger, pivoted arm with a spring attached to the opposite end

of the pivot arm. As soon as the lamp switch is closed there is a high

voltage drop across the arc circuit allowing the coil pull to overcome

the spring tension and feed the negative carbon forward. Upon striking

the arc there is a high rush of current, causing a low voltage drop

across the arc circuit, pulling the arm down and engaging the high speed

reverse feed. The negative carbon feeds back until the pull of the coil

and the spring tension just balance. Any further change due to carbon

burning back will be taken care of by the slow speed units.

The

voltage control system can be identified by looking for a regulator

coil. Voltage control will have many turns of fine wire connected in

parallel with the arc circuit. On a voltage control searchlight if the

SPRING TENSION is INCREASED the ARC LENGTH INCREASES; if spring TENSION

is DECREASED the ARC LENGTH DECREASES.

MANUAL CONTROL

Manual control gear is installed on all searchlights so the searchlight

may be operated in case of failure of the automatic system. All of the

automatic functions except ventilation can be operated manually. The

manual control gear has two small cranks located on the back of the

lamp box; one controls rotation of the positive head, the second controls

the feed of the negative carbon. A push button controls the feed of

the positive carbon.

ADJUSTMENTS

The angle of the negative carbon in relation to the positive carbon

must be correct. If the angle is too great or too small the crater of

the positive carbon will burn off on one side and allow the ball of

vapor to escape. See the lamp instructions book for the correct setting

and method of adjustment.

Figure 147. - Carbon feed heads for Sperry

36-inch searchlight.

ADJUSTMENT OF CARBON BRUSH PRESSURE

A proper contact between the heads and the carbons is necessary.

If brush pressure is too great the carbons will stick and not feed properly

and if too loose will not give good contact. When correctly set it should

take a pull of 8 to 10 ounces to slip the carbons out of the head with

the feed rollers raised.

ADJUSTMENT OF POSITIVE CARBON

PROJECTION

The positive carbon must project a distance of 9/16-inch for for

the 24-inch light, 15/16-inch for 36-inch light, in front of the positive

head. This prevents the noses from burning and assures proper focus.

To make this adjustment allow the searchlight to operate several minutes.

Then secure the light and measure the distance from the positive carbon

tip and the positive nose. If this distance is incorrect, the procedure

for adjusting follows.

If the positive carbon is not projecting

out far enough shift the lens, figure 145, in the direction you wish

the carbon to feed. Shift lens only about 1/16 inch at a time. After

the lens has been shifted the lamp must be operated several minutes,

and rechecked. This must be repeated until the projection is correct.

ADJUSTMENT OF ARC LENGTH

The first step in adjusting the arc length on a current control

searchlight is to determine the proper operating amperage. You can find

this in the instruction book on the light. If the switchboard does not

have an ammeter in the arc circuit, connect in a portable ammeter. If

the arc current is too high, decrease the spring tension. This will

lengthen the arc and decrease the arc current. If the arc current is

too low increase the spring tension. This will decrease the arc length

and increase the arc current.

For adjusting a voltage controlled

searchlight feed determine the proper arc voltage. If the switchboard

does not have a voltmeter for the searchlight, connect a voltmeter across

the arc circuit. If the arc voltage is too high, increase the spring

tension. If the arc voltage is too low, decrease the spring tension.

Always CONSULT the INSTRUCTION BOOK WHEN MAKING ADJUSTMENTS.

FOCUS

After the preceding adjustments have been made, the lamp should

be focused. A focus screw on the back of the lamp box moves the entire

lamp mechanism toward or away from the reflector. Operate the light

for several minutes then secure and measure the positive carbon tip

projection. Then measure the distance from the tip of positive carbon

to the center of the reflector. This distance should correspond with

the focal length given on the reflector.

CARBONS

In 24-inch searchlights a pair of carbons will last approximately

105 minutes, in a 36-inch light at 150 amperes, about 90 minutes and

at 190 amperes, about 45 minutes. Spare carbons should be stored in

original containers in a dry clean space.

PRECAUTIONS FOR RECARBONING

Always MAKE SURE LAMP SWITCH IS OFF WHEN RENEWING CARBONS.

IF LAMP IS HOT USE GLOVES AND PLIERS to renew carbons.

CHECK

CARBON to make sure it is not cracked or warped.

Always START

an operation WITH COMPLETE NEW SET OF CARBONS. Never use a set of stubs.

After renewing carbons operate the light for about three minutes to

form the crater in the positive carbon.

REAMING POSITIVE AND NEGATIVE

NOSES

The positive and negative noses should be reamed when needed to

remove carbon and other obstruction to insure freedom of carbon to feed.

Reamers are furnished as spare parts. The following precautions should

be followed: In reaming always hold reamer straight, make sure feed

rollers and brushes are lifted, and IF REAMING WHILE LAMP IS HOT. NEVER

ALLOW REAMER TO STOP moving UNTIL NOSE IS COMPLETELY REAMED. This is

to prevent reamer from becoming stuck as the metal cools.

CLEANING REFLECTORS AND DOME

The reflector and dome glass should be cleaned each time after the

light is used. NEVER USE POLISH CONTAINING ABRASIVES.

Use mixture

of denatured alcohol and precipitated chalk to clean reflector; the

mixture should consist of three ounces of chalk to 1/2 pint of alcohol.

This paste may be removed with cheese cloth. NEVER USE A ROTARY MOTION.

Always POLISH FROM THE CENTER OUT. Use a cloth to remove residue of

carbons from the burning interior of drum. This residue is a white powdery

ash. A small paint brush or painter's duster serves as well to remove

carbon particles from the thermostat lens and top of lamp.

LUBRICATION

The manufacturers instruction book gives information for lubricating

base, trunnion arms, and lamp. Grease or oil should never be used on

the heads. To lubricate heads use a mixture of flake graphite and kerosene

at least once a week. The iris shutter should be given a light coat

of graphite and kerosene once a month.

PERIODIC TESTS, INSPECTIONS AND CLEANING

AFTER EACH PAIR OF CARBONS -

Wipe reflector,

glass door and thermostat lens.

AFTER EXTENDED RUN -

Clean interior of drum, thermostat window and lens and the lamp mechanism.

As soon as the reflector has cooled, clean the

reflector and front door glass.

AFTER FIRING -

After each period of firing of the ship's batteries, inspect all searchlights.

DAILY -

Test local mechanical gear for training

and elevating light, then the remote control or

distant

mechanical control gear.

Check remote electrical

control gear on searchlight.

Operate each lamp long

enough to dry out drum and test functioning of lamp mechanism.

Check ready light for full pair of carbons.

At sea and during damp weather, energize remote control electrical equipment

to

insure dryness.

WEEKLY -

Clean reflector and front door glass.

Clean interior

of drum, thermostat, window and lens, and lamp mechanism.

Check nose caps for insulation to heads and to ground.

Examine exposed gears and bearings for lubrication and for freedom from

dirt, sand

and grit.

MONTHLY -

Remove, examine and clean the metal contact blocks which conduct current

to the carbons.

Clean carbon feed rollers.

AFTER 50 HOURS OF OPERATION OR QUARTERLY -

After

50 hours of operation and not less than once each quarter, remove the

lamp

from the drum, overhaul, reinstall and reset the

lamp.

YEARLY -

Inspect, lubricate, and repair

equipment in the base.

Chapter 15 Quiz

(click

here)

|