|

January 1963 Electronics World

Table

of Contents

Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

It seemed weird to read

of microelectronics device density expressed in parts per cubic foot of semiconductor

substrate. Describing density that way makes some sense when considering 3-dimensional

devices with vertically stacked elements, but this was in a 1963 article in

Electronics World magazine, so that could not have been the case. The motivation, evidently

was to be able to compare microcircuit density with that of the human brain in terms

of neuron density. In fact, there is an interesting chart presented that shows the

evolution in circuit density beginning with vacuum tube circuits, progressing through

the state of the art in 1963, projecting for future years, and finally peaking with

the brain's density. Interestingly, the brain density shows as about 5x1011/ft3,

while the "nonredundant semiconductor device" limit is 1013/ft3.

Contemporary measurements estimate a neuronal density of around 4x104/mm3

(1x1013/ft3), which is about a factor of 10-20 over a span

of 50 years (not too bad). I gave up trying to find

useful data on current transistor density in volumetric units, but in terms of devices

per mm2,

Intel is running better than 30 transistors/mm2, which,

although not really a legitimate exercise, translates to [√(30 transistors/mm2)]3

= 2x102 transistors/mm3. That means we're now at about 1/200th

of the human brain density of 4x104 neurons/mm3.

Microelectronics

By William O. Hamlin / Fairchild Semiconductor

By William O. Hamlin / Fairchild Semiconductor

The electronics industry is on the verge of

a new era with the introduction of integrated microelectronic circuits. This new

concept, now in active development by a score of laboratories, can pack over a million

parts into a cubic foot of space and, at the same time, greatly increase reliability.

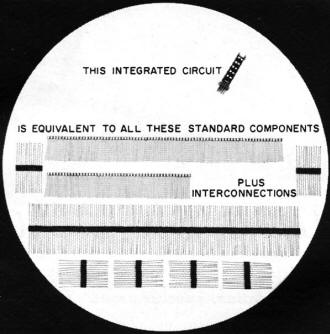

Already circuits are available in quantity, in packages only 0.3 inch in diameter

and 0.2 inch high, to build complete logic and arithmetic sections of computers.

The world's first integrated-circuit electronic control computer was announced

last May. Called "Martac 420," the new computer was built by the Martin Company

at Denver, Colorado. Designed primarily for ICBM pre-launch checkout and control,

it tests and computes the readiness of all electronics in the missile. Within the

electronic computing system, traditionally made up of transistors, diodes, and resistors,

is logic circuitry comprising only plug-in integrated circuits. These reduced a

conventional 20,000 parts to 5000 and cut over-all size to three-eighths that of

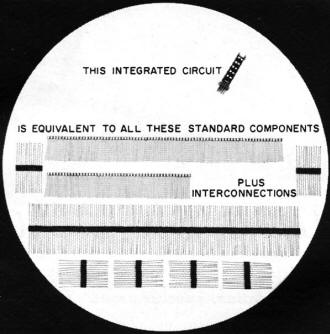

previous construction. One part of this system, a decade counter with direct-coupled

circuitry, is shown in Fig. 2. Here the integrated-circuit counter is compared

to the number of conventional parts that might have been used.

New integrated circuits being worked on in a score of laboratories

promise fantastic size reduction of much equipment, more reliability, and, eventually,

low cost.

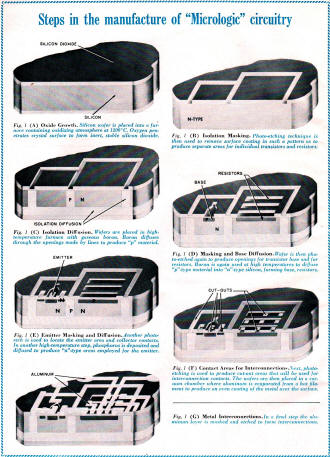

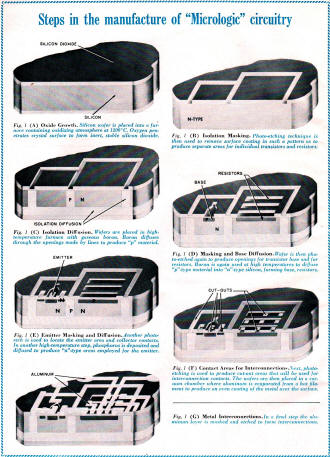

Steps in the manufacture of "Micrologic" circuitry.

Microelectronic development has been encouraged by the needs of military and

space programs. Millions of dollars are now being spent for research and development.

But, as in other areas of military research, benefits will eventually be passed

on to the public. Military and space programs require smallness, reliability, and

lightness; industry wants low cost and reliability; the public wants low cost. Microelectronic

integrated circuits offer all these things. Their appearance in all types of equipment,

military and consumer, awaits only the ability to make the wide variety of circuits

needed.

To visualize the future scale of sizes compared to present and past equipment,

the graph of Fig. 3 shows theoretical parts per cubic foot, ranging from World

War II electronic equipment to the human brain. It is difficult to conceive the

ultimate theoretical smallness, but the human brain is probably close to this limit,

having a density of over 100 billion parts per cubic foot.

Integrated circuits should perhaps more rightly be called functional blocks,

because each is a single device performing a complete electronic operation. Such

functions might include one or more stages of amplification, or several switching

stages to perform a computer logic step, such as storing numbers or counting.

Fig. 1 (A) Oxide Growth. Silicon wafer is placed into a furnace containing

oxidizing atmosphere at 1200°C. Oxygen penetrates crystal surface to form inert,

stable silicon dioxide.

Fig. 1 (B) Isolation Masking. Photo-etching technique is then used to remove

surface coating in such a pattern as to produce separate areas for individual transistors

and resistors.

Fig. 1 (C) Isolation Diffusion. Wafers are placed in high-temperature furnace

with gaseous boron. Boron diffuses through the openings made by lines to produce

"p" material.

Fig. 1 (D) Masking and Base Diffusion. Wafer is then photo-etched again

to produce openings for transistor base and for resistors. Boron is again used at

high temperatures to diffuse "p"-type material into "n"-type silicon, forming base,

resistors.

Fig: 1 (E) Emitter Masking and Diffusion. Another photo-etch is used to locate

the emitter area and collector contacts. In another high-temperature step, phosphorus

is deposited and diffused to produce "n"-type areas employed for the emitter.

Fig. 1 (F) Contact Areas for Interconnections. Next, photo-etching is used

to produce cut-out areas that will be used for interconnection contacts. The wafers

are then placed in a vacuum chamber where aluminum is evaporated from a hot filament

to produce an even coating of the metal over the surface.

Fig. 1 (G) Metal Interconnections. In a final step the aluminum layer is

masked and etched to form interconnections.

Various Design Techniques

One form of microelectronic circuit in common use today is made from a single

silicon semiconductor crystal, with no external circuit wiring or components. Wiring

is thus reduced to between-circuit interconnections, which may be printed boards.

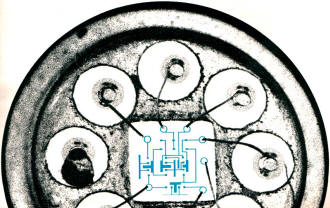

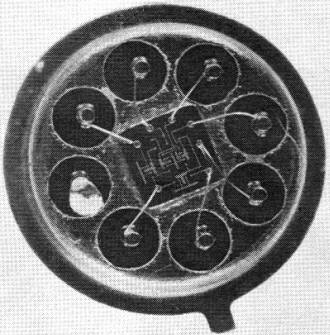

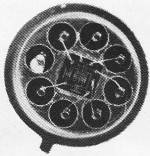

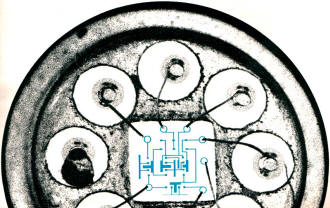

A typical integrated functional block is shown in Fig. 4. This is a half-shift

register for computers, containing 9 transistors and 14 resistors all mounted within

an 8-lead transistor-type can.

Intermediate approaches to microelectronics usually comprise the high-density

packing of components, either on or in wafer substrates, or bunching components

together like cordwood with welded connections.

Another technique, called "thin film," involves the evaporation of desired metals

on the substrate. With suitable masks or stencils, and the right choice of metals,

it is possible to form all of the passive components (resistors, capacitors, and

inductors) plus interconnecting wires. But it is still necessary to insert individual

transistors and diodes.

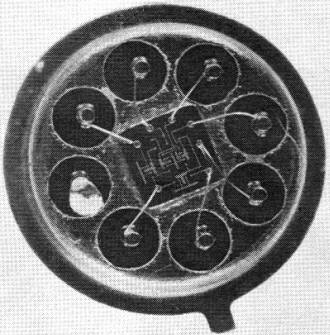

Fig. 2 - Decade counter module and parts that it replaces.

Fig. 3 - Packing density for systems and components.

Fig. 4 - "Micrologic" element containing 9 transistors and

14 resistors on base 70 mils square, which is then inserted into the 8-pin transistor

case illustrated at the right.

Fig. 5. "Micrologic" element shown mounted in transistor

case (enlarged 6 times).

The most promising microelectronic concept at present, for versatility in serving

both computer and communication needs and practical to construct with present scientific

knowledge, seems to be the solid-state integrated functional block.

Maximum Reliability

For military and space electronics the reliability consideration is probably

uppermost. Electronic systems used with weapons, aircraft, communications, and the

control, launching, and tracking of orbiting or space vehicles, is fantastically

complicated and will be more so in the future. For example, the over-all reliability

of a system equals the product of the reliability of each of its parts. If the system

has three parts, each with a 90 percent chance of success, then the chance of the

system for successful operation is (0.9 x 0.9 x 0.9 = 0.73) 73 per-cent. With perhaps

billions of components involved in multi-million dollar space shots and with men's

lives at stake, the expectation of success must be very much greater than that and

the problem is infinitely more complex.

Experience has shown that deep inspection and extensive quality control are still

not adequate to assure high reliability. Costs are too high and errors can be introduced

into the controls themselves. Therefore, a reduction in the number of individual

components, by making them part of an integrated circuit, is the only practical

way to meet this urgent need. Putting it another way, the more components, the greater

the chance of failure.

Fabricating the Circuit

To make an integrated functional circuit, which will provide the active functions

of diodes and transistors as well as the passive components, one begins with a material

having semiconductor potential, such as silicon. The properties necessary for semiconductor

electrical characteristics then require the introduction of impurities into the

silicon crystal. These impurities become the current carriers, since the pure crystal

is not a good conductor. The atoms of the impurity must be able to combine with

the crystal structure in such a way that an electron is either added or taken away.

The first impurity type is called n and the latter p, for negative and positive.

(After Wallmark and Marcus, "Proceedings of IRE," March, 1962)

If p and n characteristics are formed alternately in the same material, then

an electrical barrier is formed. This barrier will allow current to flow readily

when a battery is placed across it with the negative terminal to the n type and

positive to the p type. But on reversing the battery a high resistance is presented

to current flow.

With present technology, one efficient way of making integrated circuits with

silicon is to introduce a small amount of n impurity into the entire ingot. Then

the n polarity is either counteracted as required by the addition of p impurity,

or the n characteristic is strengthened by increasing its concentration.

In the manufacture of integrated circuits these impurities are added to the circuit

substrates by diffusion. The units are placed in a high-vacuum furnace and, at an

elevated temperature, a gas containing the desired impurity is introduced so that

the impurity comes in contact with the substrate and penetrates its surface. Other

methods of adding impurities to semiconductors, such as alloying, are not suitable

for integrated circuits. The diffusion method is the same as used for the manufacture

of modern high-frequency silicon transistors.

The great advantage of the diffusion method is that many units can be placed

simultaneously in the furnace to make thousands of devices. With all being exposed

to the same conditions, their uniformity is high, and production yields are high,

because once the process is perfected each individual device tends to be as good

as the whole.

The patterns of diffusion on the substrates are formed by a photolithographic

process similar to that used for etching plates in printing. Very fine details are

possible, limited only to the degree of control over the precision camera work,

the making of masks for the patterns, and the alignment of the masks in successive

manufacturing steps.

Both active and passive components are made into the silicon substrate material

by the same diffusion processes. The methods employed for the several types of components

follows:

1. Resistance is controlled by varying the amount of diffusion of impurities.

More impurity lowers resistance. The photolithography pattern determines length

and width.

2. Capacitors are formed in two ways. In one method, p-n junctions (barriers)

are used, which inherently exhibit capacitance when reverse biased. In the second

method, capacitors are formed on the surface, with silicon dioxide acting as the

dielectric.

3. Inductors of limited value can be formed by diffusing-in a heavy concentration

of an impurity in a spiral pattern. Considerable development is still required in

this area, however.

4. Transistors and diodes are made by successive diffusion of their parts. These

can be made at the same time as the passive parts, if the impurity concentrations

are the same.

"Micrologic" Manufacturing

Typical microelectronic integrated circuits, known as "Micrologic" by Fairchild

Semiconductor, are made by means very similar to those used for diffused "planar"

transistors. This is a device whose surface is in one plane, with the base and emitter

contacts on the upper surface, and the collector integral with the substrate material.

The previous generation of transistors was the "mesa" type, which involved etching

away of the surface to control and reduce the size of the base area. True planar

transistors have a hard protecting surface of silicon dioxide, formed by an oxidizing

atmosphere introduced with the diffusions.

The "Micrologic" manufacturing steps, from the preparation of the ultra-pure

silicon crystals to final inspection and capping, are shown in Figs. 1 and 5. Some

60 to 100 circuits are formed simultaneously in one wafer, and dozens of wafers

can be diffused at one time. This batch processing leads to lower and lower costs.

The completed unit with leads attached is evaluated for reliability and electrical

performance, by a unique method of testing. Since individual components cannot be

tested, the entire function is checked for performance over the specified voltage

and temperature ranges .

Of the several approaches to micro-electronics now under investigation, the integrated

circuit seems to have an excellent chance of long-range and universal use. Reasoning

behind this statement is the integrated circuit advantages of inherently high reliability,

the ingredients required for mass production, and consequently, low cost.

Other types will have varying degrees of popularity. The microsized discrete

component may lose favor when integrated circuit development permits all desired

functions to be served by them. The drawbacks of the discrete micro-component approach

are failure to reduce the number of interconnections and high cost.

Thin-film circuits will logically be used with integrated circuits to give greater

flexibility and a wider range of circuit values than possible with diffusion alone.

But with advanced integrated circuit technology, the thin-film circuit with individual

transistors and diodes will no longer be required. Admittedly, however, the transistor

was announced only 14 years ago and we have probably only scratched the surface

of the potential capability, materials, and technologies. Already gallium arsenide

is being investigated for its higher frequency potentiality. Cryotrons, which switch

at zero resistance with very low temperatures, have been found adaptable to thin-film

production. And the field-effect transistor is coming into its own as a high-impedance

amplifier, competing with vacuum tubes.

The success of the integrated circuit principle, however, whether in the form

described here or in some form yet to be discovered, seems to be assured, because

of the needs of our modern electronic world. It is not too farfetched to visualize

them in all types of industrial and consumer equipment in the next five years or

so. They will probably be seen in broadcast and communications equipment, in hi-fi

gear, in household electronic controls, and in small business computers.

By William O. Hamlin / Fairchild Semiconductor

By William O. Hamlin / Fairchild Semiconductor