|

When I look at a photograph of

ancient buildings, bridges, and other constructs that required years of planning

and labor to complete, I think of how unfortunate it is that a history of drawings

and/or paintings do not exist that document the construction process that went into

it. Other than more contemporary renditions of what an artist thinks the sites of

the Great Pyramids, the Parthenon, the Great Wall of China, etc., might have looked

like as workers (often slaves) and engineers progressed throughout the projects,

very few instances exist.

I also wish to see the off-site manufacturing of columns and pillars, carved wooden

and stone facades, stained glass windows and decorations, furniture, pottery, swords

and cannons, and all the things that make up the entirety of the project. Let us

also see renderings of the transportation of those components to the worksite. Once

the photographic process was invented, we slowly but surely were treated to such

documentation of construction history. It is nice to see the faces of the people

who helped to build the modern world, and it would be nice to see those who built

the ancient world. This advertisement by the Sangamo Electric company's factory

is what I would like to see from the workshops of craftsmen of yore.

Here are a few more examples of Samgamo advertisements in the

September

and December

1949, May 1950,

April

1954, and June

1956 issues of Radio & Television News.

Sangamo Electric Company High Reliability Capacitors

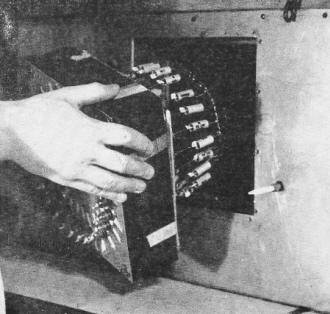

Separate facilities are maintained for the exclusive processing

and manufacture of high reliability capacitors. Only specially trained, highly skilled

operators, who wear special clothing to prevent any possible source contamination,

work here.

Oil-filled capacitors are subject to vacuum under elevated temperatures,

then are individually examined to insure complete hermetic seal.

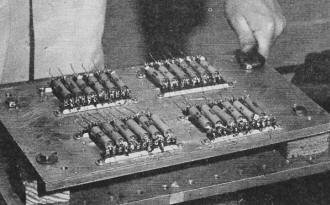

To produce capacitors free from any possibility of latent defects, for use in

the most critical applications, the Sangamo Electric Company has recently intensified

its high reliability program of fabrication and inspection methods.

Incoming materials are rigidly inspected to meet stringent high reliability standards

and are stored in areas where temperature, humidity and dust are controlled at all

times.

Complete production histories are kept on the basis of small capacitor lots.

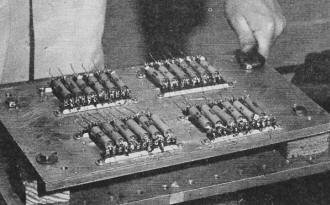

X-raying of individual units, heat tests, vibration tests, altitude tests, and total

destruction tests of a given percentage of all finished units assure components

with an extremely low AQL. Testing facilities and resultant performance characteristics

are far in excess of military specifications. Specify these high reliability capacitors

for your critical applications.

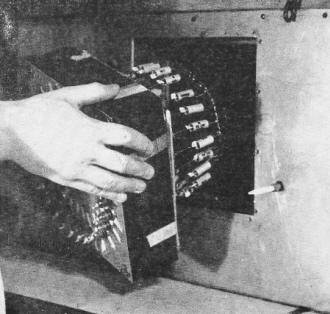

High temperature test ovens are used to check insulation resistance

of Sangamo high reliability capacitors under sustained temperatures of 125°

C.

This vibration testing machine brutally punishes Sangamo high

reliability capacitors at accelerations up to 10 G's to determine their ability

to resist vibration without damage to leads or elements.

Sangamo Electric Company

Marion, Illinois

SC56-2

Posted May 30, 2019

|