August 1939 QST

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

QST, published December 1915 - present (visit ARRL

for info). All copyrights hereby acknowledged.

|

Polystyrene has been commonly used in capacitors since long before I came on

the electronics scene. Its widespread use in electronic and electrical components

was first adopted in Europe in the 1920s, and then later became popular in the U.S.

where scientists improved its characteristics and lowered its cost to where it could

be found just about anywhere current flowed. This 1939 QST magazine article

provides a brief introduction to polystyrene. In its present-day form, polystyrene

can be easily bent, cut, turned, polished, melted, drilled and tapped - truly a

versatile material. While polystyrene capacitors offer excellent electrical characteristics,

they are relatively large in size compared to modern capacitor technologies. As

a result, their usage has become less common in recent years, with other smaller

and more cost-effective dielectric materials dominating the market.

Polystyrene: Its Electrical and Mechanical Characteristics

How to Use it in Amateur EquipmentBy Herbert S. Riddle, W1DSK

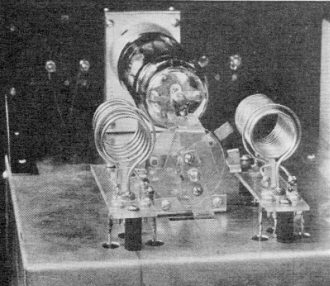

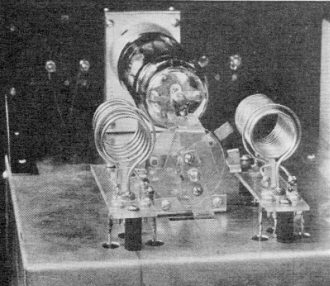

An example of how polystyrene can be worked. The switch shown

here was constructed by the author from sheet material. Note how the upper part

of the stationary member is bent over to form a support and terminal for the plate

cap of the tube.

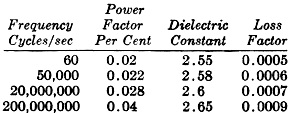

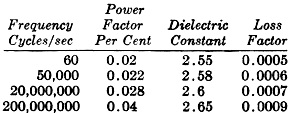

Table 1 - Polystyrene electrical characteristics.

Polystyrene is a transparent solid dielectric, formed by the thermal polymerization

of monomeric styrene, C6H5CH:CH2. This first sentence

disposes neatly of the chemical side, and from here on we can interest ourselves

only in the physical and electrical properties of polystyrene, and its application

in amateur transmitters.

Several years ago, in Europe, rapid strides were made in the molding of small

electrical parts from polystyrene materials, and it was not long before a few of

the radio parts manufacturers in this country were doing the same. The polystyrene

material was imported from England in the form of crystals or coarse powder, and

compression molded to the required shapes. The pieces produced by this method were

very expensive because the cost of the polystyrene crystals of powder produced abroad

was between two and three dollars per pound, plus duty. This imported material had

other disadvantages aside from high cost, such as a very low softening point, lack

of clarity, and instability when exposed to sunlight. The United States is now foremost

in the development and use of new plastic materials, and a domestic polystyrene

is now produced which has electrical properties equal to those of fused quartz,

excellent water resistance and dimensional stability up to 184(degree)F.

The electrical qualities vary little with frequency, as shown in the Table 1.

These extremely low-loss characteristics, comparable only to fused quartz, are

maintained even under very adverse moisture conditions; tests show 0.00 per cent

water absorption after 48 hours immersion, and 0.05 per cent after over 300 hours

immersion. The dielectric strength is about 500 volts per 0.001 inch, in thickness

of 1/8 inch.

In appearance polystyrene resembles glass, being a very light (specific gravity

1.05), non-inflammable transparent solid, the usual form being sheets, rods, or

tubes, with polished surfaces. The clarity of this material is so great that news

print may be read through a solid polystyrene rod 24 inches long. The material also

sounds like glass when dropped or thrown upon a hard surface, but polystyrene differs

from glass in that it does not break.

With a little care, no difficulty will be experienced in fabricating the material

to any shape; however, it may be well to outline a few general rules to follow when

working it:

Sawing - Strips of sheets are easily sawed to size with a regular hack saw, backing

up the polystyrene with a piece of board to prevent burring of the cut edges. The

sheet may be scribed with a sharp point as a guide to sawing. The sheets cannot

be cracked off in a straight line by scribing one or both sides as with glass. The

sawing must be done at a reasonably slow speed so that the saw blade will not become

hot and cause softening of the material, and consequent sticking of the saw.

Drilling - Care must be exercised in center punching, because a heavy blow with

a center punch may cause a small "star" fracture. The drilling should be at slow

speed to avoid heating of the drill and softening of the material. Polystyrene drills

are readily as Bakelite.

Tapping - No difficulty is experienced in tapping, using a hand wrench.

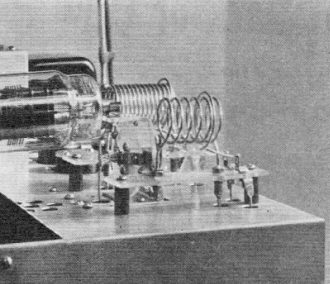

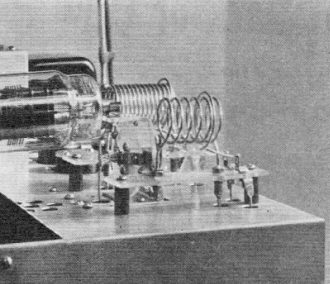

A good way to make a link mounting. Polystyrene is easily cemented.

Turning - As with sawing and drilling, cutting must be done at slow speed to

avoid heating of tool and material.

Polishing - Sawed edges may be finished with a file and then buffed to regain

the glass-like surface. The buffing must be done very lightly.

Bending - Polystyrene may be bent or formed into various shapes, but must be

heated to over 200(degree)F. In the case of smaller strips to be bent into angles,

this may be done by holding that portion of the strip to be bent about one-quarter

inch from the soldering iron until the material has softened. The strip may be readily

bent to the desired shape, and sets immediately, the bent portion being fully as

strong as the original sheet. Larger sheets may be bent to different shapes by inverting

the family flat iron, covering it with several layers of cloth and placing the polystyrene

sheet on the cloth. A pair of heavy cotton gloves is of great help in handling the

hot sheet.

Cementing - The material may be readily cemented to itself by the use of toluol,

a solvent for polystyrene. The best procedure is to clamp the two pieces to be cemented

in the proper position and apply toluol to the joint. The toluol will run into the

joint, dissolve the material to provide a bond and then dissipate, leaving a strong

joint. A joint thus made may be handled in just a few minutes but does not obtain

its full strength for several hours.

Polystyrene is an insulating material known by various trade names, the most

familiar of which is "victron." The acknowledged leader in point of low losses,

its mechanical properties are such as to make it ideal for some applications, unsuitable

in others. Recent developments in manufacture have raised the softening point and

lowered the cost to an extent which will encourage its wider use in amateur equipment.

Polystyrene material is very adaptable to the construction of coil supports and

switches, condenser strips, and similar insulators for medium- and high-power amplifier

stages. The photograph shows the plate cap support and plate lead switch of the

100-watt output buffer in the writer's transmitter, switching pre-tuned 14-Mc. and

28-Mc. tanks. This stage may be switched when in operation.

Heat - No difficulty has been experienced from tube inductance heat in actual

operation. Care should be taken, however, about soldering the lugs or other hardware

in direct contact with the polystyrene, since the high temperature will cause temporary

softening of the material under the lug.

The greatest need for a good dielectric is in the tank circuits of our transmitters.

In the writer's transmitter, polystyrene was substituted for condenser strips and

coil mounting strips of other material, which had actually swelled and bubbled up

to almost twice its thickness because of heat developed by the power leaking through

it. Several other transmitters have been changed over to polystyrene insulation

in the final tank circuit, and the increased efficiency and output have been surprising.

In one case substitution of polystyrene for a bakelite type insulation on the tank

condenser, tank coil and neutralizing condenser of a 14-Mc. 'phone transmitter resulted

in a power output increase of 40 per cent. No other changes were made in the circuit

or input.

This article is in no sense a technical treatise on all the characteristics of

polystyrene. The coincidence that the writer is both an amateur and connected with

a chemical company specializing in the field of plastics gave us the opportunity

to try this material in our own outfit and those of a few friends. The results obtained,

plus the fact that polystyrene is bound to find increasing use as a radio insulator,

particularly for use at ultra-high frequencies, justified an article summarizing

the electrical characteristics of this material and the methods of using it.

Posted May 18, 2023

(updated from original post

on 10/18/2013)

|