|

May 1946 Popular Science

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Popular

Science, published 1872-2021. All copyrights hereby acknowledged.

|

Some of the earliest printed

circuit boards were literally printed onto a ceramic substrate using silk−screening

techniques. For that matter, silk cloth was used as the pattern mask; hence the

name silk−screen. A paste of silver particles was squeegeed through the mesh, and

the resulting circuit pattern was fired in an oven to solidify and adhere the

metal to the substrate. Holes were then drilled to accept component leads. After

inserting the leads through the holes, hand-soldering completed the assembly. It

was a game-changing technology. Not only was time and space saved and a more robust

product the result, but the process eliminated miswiring and made tracing out interconnections

much simpler when troubleshooting. According to this 1946 Popular Science

magazine article, the motivation for developing this technique was the proximity

fuse during World War II. Ditto for the tiny "peanut tubes" used. Necessity

is the mother of invention, as the saying goes.

Printing Radio Sets on Calling Cards

Minute radio circuit "printed" below is actually the same as

the conventionally assembled one at the left.

Tiny Circuits of Silver "Ink" Baked on Ceramic Base Plates

By Hartley E. Howe

Techniques borrowed from the graphic arts now "print" whole radio circuits. The

maze of wiring is replaced by a pattern of silver "ink" on a ceramic base as hard

as a gem. Resistors are sprayed on. Condensers are paper-thin disks. Tubes are the

size of flashlight bulbs. The result is a circuit that is not only extremely compact,

but rugged, simple to check and repair, and easy to manufacture quickly and precisely.

Once again one industry has borrowed a process from another, as in the adaptation

of paper-making techniques to tin-plate manufacture. In this case, it is the familiar

silk-screen process used in printing labels, posters, and textile designs. With

it, a master circuit can be reproduced simply and exactly from a pattern almost

as easily as a calling card is printed.

Behind the new application of this old process lies a wartime search to perfect

one of our most potent secret weapons, the proximity fuse (PSM, Dec. '45, p. 86).

This deadly gadget enabled an antiaircraft gun to knock down a hostile plane without

a direct hit, by an elaborate electrical hookup that exploded the shell as it neared

the target. The fuse, no longer than an ordinary radio tube, carried a completely

self-contained turbogenerator, control circuits, safety devices, and an entire radio

transmitter-receiver.

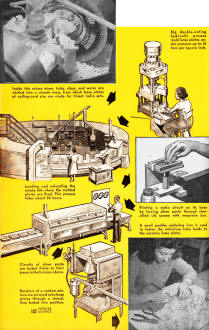

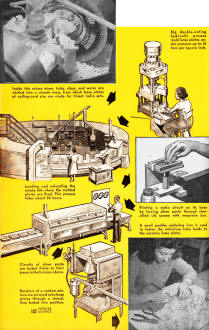

Inside this rotary mixer, talcs, clays, and water are whirled

into a smooth mass, from which base plates of calling-card size are mode for tiniest

radio sets.

Big double-acting ,hydraulic presses mold base plates under pressure

up to 10 tons per square inch.

Loading and unloading the rotary kiln where the molded plates

are fired. This process tokes about 24 hours.

Printing a radio circuit on its base by forcing silver paste

through stenciled silk screen with neoprene bar.

Circuits of silver paste are baked firmly to their bases in the

furnace above.

Resistors of a carbon mixture are sprayed onto base plates through

a stencil, then baked into position.

A small penlike soldering iron is used to fasten the miniature

tube leads to the ceramic base plate.

The space problem was tough enough, but a worse one was the terrific impact that

the fuse had to sustain at the moment of firing - equal to a blow 10,000 times its

own eight. Conventional wired circuits just couldn't take it.

The whole problem was turned over to the National Bureau of Standards, working

with the Centralab Division of Globe Union, Inc. Centralab had a lead toward a solution.

Before the war its researchers had worked on a way to build capacitors and resistors

by bonding silver to ceramics. Now they applied the principle to whole circuits

- wiring, capacitors, and resistors all on one ceramic base. It worked; the proximity

fuse began smelling out and destroying enemy planes in upper space - and today's

printed circuits are available for peacetime uses.

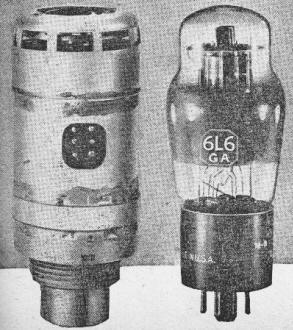

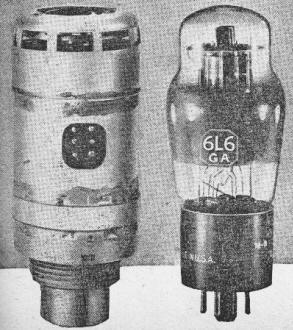

Methods developed to build an entire radio transmitter-receiver

into the deadly proximity fuse, here compared in size to a standard radio tube,

are used in printing radio circuits for commercial purposes.

First step in printing a circuit is to make a pattern, which is photographed

and printed on a silk screen coated with sensitive emulsion. The portions masked

by the pattern are water-soluble and can be washed away, leaving the exposed emulsion

on the silk in a stencil pattern of the circuit.

The "ink" is finely divided metallic silver or silver oxide mixed with binders

and solvents to form a paste. This is spread on the screen, which is placed on the

ceramic base plate. A neoprene bar is then pulled along the screen, forcing the

silver through the stencil onto the surface of the plate to print the circuit. The

silk mesh makes the deposit uniform throughout. It is fixed in place by baking it

at a temperature between 1,300 and 1,500 degrees. The heat removes the solvents

and binders and leaves the pure silver bonded to the plate with a tensile strength

of about 3,000 pounds to the square inch.

The circuit completed, the next step is to add the resistors. These are also

"ink," but a different compound: a conducting material such as finely divided carbon,

an inert filler, a binder and a solvent. By combining proper proportions of these

elements, and making variations in the dimensions of the resistor, exact resistances

can be made ranging from 3 ohms to 200 megohms.

The carbon mixture is sprayed on the base plate through a stencil, and after

air drying the plates are again baked, this time at the much lower temperature of

300 degrees. After being coated with resin the resistors are highly stable under

heavy loads or high humidity.

The capacitors or condensers are the third element to be added to the circuit.

These are also of a novel type: paper-thin ceramic disks, silvered on both sides

and from 1/8 to 3/8 of an inch in diameter. Attaching these tiny capacitors to the

base plate is a delicate job. A low-temperature bismuth solder must be used because

the heat of normal soldering would crack the thin condenser plates. In addition,

two percent silver must be added to the solder to prevent it from absorbing the

silver from the base plate.

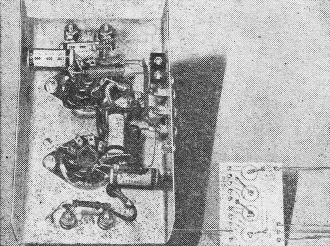

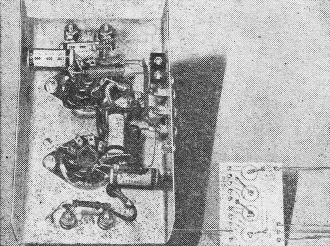

The bottom of a regular radio chassis, with its clutter of wires

and parts, contrasts strikingly with the compact base plate of a printed radio circuit,

shown at a comparable stage of assembly.

Since ordinary solder would soak up the circuit, silver solder is also used in

the final step, adding the tubes. The new tiny tubes developed during the war, highly

efficient, rugged, and with an extremely low-filament drain, are used to keep the

unit compact.

The plates on which the circuits are printed are made of a ceramic called steatite.

When molded, under great pressure, the plates are chalklike. To shrink and harden

them, they are dipped in glass-forming materials and fired in kilns at around 2,400

degrees Fahrenheit. When they come out they are hard enough to cut glass. Steatite

will not absorb water, solvents or acids even when completely submerged - extremely

important for electrical use.

Centralab does not plan to produce complete radio sets itself but rather component

parts, including amplifiers, filters, control circuits and small subassemblies,

for other manufacturers. Subcircuits printed on plates plugged into the main chassis

are as easy to change as a tube. This is particularly important in the export trade:

radio repairmen are few in remote areas and a plugged-in circuit that can be bought

as a unit, like any spare part, will enable the owner to make his own repairs.

Vest-pocket radio telephones to be carried by individuals still lie in the future

but there are many immediate uses for the tiny circuits. Hearing aids can be made

far smaller and more compact. Meteorological instruments can be lighter and stronger.

Electronic controls of all sorts, in fact, will benefit from the ruggedness and

simplicity of the silver circuits, and from the small amount of space they occupy.

Posted November 28, 2023

|