Centralab Ceramic Capacitors |

||

Maybe it isn't so anymore, but according to Centralab the ceramic raw materials available in abundance in America were electrically superior to those being used in Europe since the early 1900s when German scientists first discovered the dielectric properties of the material. Ceramic capacitors represented a major advance in capacitor technology over liquid and paste dielectric types in most areas of electrical and mechanical specifications such as vibration, aging, vibration and shock, temperature, value stability, voltage and current handling, etc. Centralab ran this advertisement in Radio & Television News magazine spelling out all the virtues of ceramic capacitors that had accumulated due to their research efforts. Philips Electronics' Components division bought Beyschlag and Centralab and merged the two into "BCcomponents," whereupon in 2002 Vishay bought them. Know "Why" Ceramic Capacitors and You'll Buy Ceramic Capacitors

Choose the exact capacitors you need from the world's widest line of ceramic capacitors - for jobs that demand the best in guaranteed TV-AM-FM servicing ... Up until a few years ago, capacitor design was based on one idea - "the bigger the better." Paper and mica, etc., were cheap, readily available materials, and their use was the only known art for making commercial capacitors (or "condensers" as they used to be called). Now don't misunderstand us ... those old condensers were really OK as far as they went. But today there's something more to talk about ... Ceramic Capacitors.

Let's take a look at modern ceramic capacitors and the story behind them. It was in the early 1900's when German scientists discovered the dielectric properties of ceramic materials. In the U.S.A., we had an abundant supply of mica and other materials, so U.S. research men never bothered with ceramics. Then came World War I, and ceramics became mighty important in European radio manufacture. Ceramics were a long way from perfected but they did the job ... and continual improvement made them increasingly important in the electronic field. Meanwhile, at Centralab, we had started to investigate these new materials. It was soon found that U.S.A. had a bigger source of raw ceramic materials and that our stocks were of vastly superior physical and electrical characteristics.

In a few years, Centralab put on the market its first ceramic capacitors. With World War II, came tremendous developments in electronics. Radio, radar and other electronic equipment demanded the finest in component parts ... and ceramic capacitors came into their own. In fact, independent research has shown that during World War II, in some classes of military equipment, there was not a single known instance of a failure of a ceramic capacitor! Thus, through the lessons learned over a period of 20 years of intensive research - Centralab Ceramic Capacitors have today become the best capacitor buy for safe guaranteed servicing. For when you use CRL ceramic capacitors, you're using the benefits of hundreds of thousands of man-hours of research-experiments with over 20,000 different ceramic compounds!

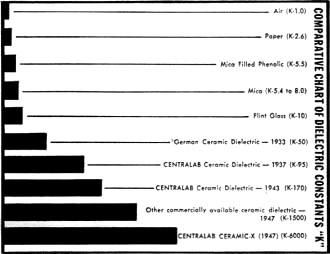

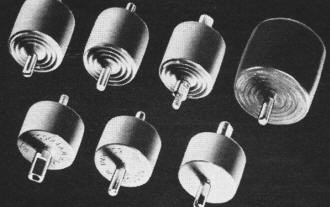

For example, every serviceman is aware of the moisture absorbing quality of paper condensers ... and how moisture can seep in along the leads on mica units. Compare these old designs with modern ceramic tubular and disc types ... Centralab's Ceramic-X capacitor bodies are nonhygroscopicc... moisture absorption being only 0.007% or less! That fact alone means Centralab Capacitors give you and your service customer the ultimate in reliability - even under severe tropically humid conditions.... moisture absorption being only 0.007% or less! That fact alone means Centralab Capacitors give you and your service customer the ultimate in reliability - even under severe tropically humid conditions. Old-timers in the service field ... yes, and young ones, too, will recall the bulky size ... the difficulty of handling old-fashioned large size capacitors ... when size seemed to be an important factor in design. Now, look at modern ceramic capacitors. They're less than 1/7 the size ... you can fit them anywhere! When you look at this chart of the development of capacitors using various materials ... the tremendous improvement of the dielectric constant "K" with the entry of ceramics into the field is dramatically evident. One of the most serious problems with old-time capacitors was that they broke down under high temperatures. Here again, ceramics have more than proven their superiority. 85° C. will not harm the modern ceramic capacitor. In fact, the ceramic body itself can easily withstand any temperature encountered in electrical apparatus. High capacity is well maintained under wide temperature variation. What's more, the copper-silver electrodes are electro-bonded to the ceramic with a tensile strength of 30,000 lbs. per square inch - thus preventing any possible change of the relative position of the electrodes. A typical example of the high degree of perfection and performance offered by ceramic capacitors is contained in CRL Hi-Vo-Kaps, These units are rated at 10-20 and 30 KV and are intended exclusively for TV. You'll find that practically the entire TV industry has standardized on these CRL units as original equipment for this most exacting application. Ceramic Disc H-Kap Capacitors - provide very high capacity in extremely small size, with minimum thickness. For by-pass, coupling and general applications. Superior power factor and low inductance. TC Temperature Compensating Ceramic Capacitors - stable units that do not change in capacity under wide temperature variations - or may be selected to correct for frequency drift in resonant circuits caused by temperature changes. Also superior replacement for close tolerance micas. Television High Voltage Capacitors - are the accepted standard for the TV industry. Used for filter and by-pass in TV high voltage power supply and pulse filter for cathode ray tubes. Ask for Centralab Hi-Vo-kaps. Capacitor Kits - several are available. Illustrated is assortment of 200 units of most generally used values, supplied in a four-drawer metal cabinet. Often assures required values will be on hand when needed in labs or for service. No charge for cabinet. When it comes to low power factors - check ceramics against all others. With ceramics, initially it's 0.1 % to 0.6%. After 100 hours at 95% humidity, it's 0.5% to 3% and they'll return to normal! That's ceramic high efficiency! If it's accuracy you want, ceramic capacitors can give you unusually close tolerances in wide range of values.

Service-engineers today are called upon for more exacting work - more downright customer satisfaction. Every job that comes into you shop is a challenge to your reputation. Regardless of the care in workmanship. no service job is better than the components you put into it. To stay in business tomorrow - you can't take chances today. Field research shows that smart service-engineers everywhere are replacing all old-fashioned or dangerously old capacitors with ceramic capacitors, within the capacity ranges available. Particularly if there is any indication of possible failure within a reasonably short period. For by-pass and coupling applications ... they're using Centra lab BC Hi-Kaps. For tuning applications, they're using temperature compensating TC Hi-Kaps. It's their own assurance of a good job well done ... and their customer's insurance of complete satisfaction. What's more, to the serviceman and customer alike ... there's little or no premium in price. You'll find Centralab ceramic capacitors are available in a wide variety of capacities from any recognized better radio parts distributor. Ask him. And remember, Centralab is the pioneer in the field of electronic ceramics. That fact alone is your best assurance of engineering know-how, production know-how, and performance know-how that permits no compromise with quality. Yes, for the safest, quickest guaranteed servicing ... standardize on Centralab Ceramic capacitors. You'll have the world's widest line to select from - as made by Centralab, America's pioneer builder of ceramic capacitors. You can get complete information on all the capacitors described here - plus other valuable service information from Centralab's Catalog 27 ... available at your distributor's. Ceramic BC Tubular Hi-Kap Capacitors - for by-pass or coupling applications and most general circuit work. Smallest size on the market. Remarkable stability under high temperatures or humidity. Transmitting and High Accuracy Ceramic Capacitors - for applications involving rigid frequency control. Used for holding oscillator frequencies to close limits. Excellent as secondary Standards.

Centralab Division of Globe-Union Inc. 910 E. Keefe Avenue Milwaukee 1, Wis.

Posted July 11, 2022 |

||

Here are the facts about Ceramic Capacitors -

why they are the most permanent capacitors ... why they do a better job ... give

a" better performance

Here are the facts about Ceramic Capacitors -

why they are the most permanent capacitors ... why they do a better job ... give

a" better performance  Actually, the idea of ceramic capacitors isn't

new. They've been used as electronic components for more than 20 years. We call

them new because it's only in the last few years that service-engineers have paid

any attention to them ... and because some of these modern ceramic capacitors really

are new ... with new higher voltages, new and better physical characteristics. So

if ceramic capacitors were overlooked by service-engineers during the last few years

... we feel it's because you didn't know about just how good they really are - or

because what you needed wasn't available.

Actually, the idea of ceramic capacitors isn't

new. They've been used as electronic components for more than 20 years. We call

them new because it's only in the last few years that service-engineers have paid

any attention to them ... and because some of these modern ceramic capacitors really

are new ... with new higher voltages, new and better physical characteristics. So

if ceramic capacitors were overlooked by service-engineers during the last few years

... we feel it's because you didn't know about just how good they really are - or

because what you needed wasn't available.  Then one of our foreign representatives supplied

us with a complete set of foreign-made ceramic components. Result - Centra lab developed

a ceramic research program. The program was big and thorough ... and it's still

going on.

Then one of our foreign representatives supplied

us with a complete set of foreign-made ceramic components. Result - Centra lab developed

a ceramic research program. The program was big and thorough ... and it's still

going on.

Yes, and if you compare the old-style paper

and mica capacitors with modern ceramic capacitors ... point for point, based on

your own technical experience, you'll see why ceramics are vastly better ... the

safe, dependable way to assure a good service job.

Yes, and if you compare the old-style paper

and mica capacitors with modern ceramic capacitors ... point for point, based on

your own technical experience, you'll see why ceramics are vastly better ... the

safe, dependable way to assure a good service job.

In r.f. circuits, where drift is critical, one

of the likely causes is temperature change. Stabilization can be effected by capacitors

which compensate for temperature variations. Centralab pioneered ceramic capacitors

for this purpose. This important research resulted in Centralab's famous TC-Hi-Kaps

Zero Temperature and Negative Temperature Compensating units. These are a Centralab

exclusive "First". For service-engineers they are the industry's last word in accurate

stabilizing capacitors.

In r.f. circuits, where drift is critical, one

of the likely causes is temperature change. Stabilization can be effected by capacitors

which compensate for temperature variations. Centralab pioneered ceramic capacitors

for this purpose. This important research resulted in Centralab's famous TC-Hi-Kaps

Zero Temperature and Negative Temperature Compensating units. These are a Centralab

exclusive "First". For service-engineers they are the industry's last word in accurate

stabilizing capacitors.