How Much Will a Resistor Take? |

|

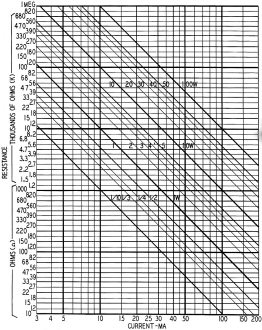

Here is a good treatise on resistor ratings - voltage, current, and power - with and explanation and handy-dandy chart for helping you figure out what type of resistor you need to suit the task at hand. It appeared in the March 1953 issue of Radio-Electronics magazine, at a time when resistors the size of a grain of salt were not invented yet (or for that matter even tinier resistors on semiconductor dice), but the principles are still the same. I do take issue with author Manly's assertion that there only being one reason resistors fail: "The burnout occurred only because the resistor carried too much current." He cites the failure (electrical and mechanical) of connected components often being responsible for the excess current, but does now allow for a mechanical failure of the resistor itself. A factory manufacturing defect or being subject to excess vibration, temperature or shock can cause resistor failure. So can "walking wounded" type damage done during the assembly process due to mishandling. I do like the description given of the visual signs of an overheated resistor right up to the point where the functionality-giving smoke escapes and the resistor stops working. The ins and outs of wattage ratings. Wattage rating chart. Wattage is read on nearest diagonal line above intersection of current and resistance lines. By H. P. Manly At 4:45 pm the new flyback transformer was in place, connections checked, joints soldered, leads dressed where they belonged. Less than 30 seconds after turning on the power a picture appeared and it didn't look bad. At 4:48 pm the picture flickered, and smoke curled up through ventilating holes around the power rectifier. It happens to all of us sooner or later, maybe both times. One of the hundred-odd resistors under the chassis burn out. Locating the victim isn't too difficult. We may look for the black and blistered remains, feel for the heat, smell around for the unmistakable aroma of a burnout or, as a last resort, use the ohmmeter. There is just one reason why a resistor burns out. Of course, the contributing cause may have been a shorted capacitor; the coating may have dropped off a cathode and landed against the plate of a rectifier; some tube might have gone suddenly gassy - but none of these are the direct reason for the burnout. The burnout occurred only because the resistor carried too much current. It carried too much current because it was subjected to too much voltage. Let's consider what actually might happen. Assume that a short or some other fault applies 200 volts across an 8,200-ohm resistor. That resistor then carries about 24 ma. (Volts multiplied by 1,000, and the product divided by ohms, equals milliamperes.) When that much current is forced to flow against that much resistance, heat is produced. In this case nearly 5 watts of electric power is being used in the production of heat. (Current squared, and multiplied by resistance, equals power.) A resistor of good quality, rated at 5 watts, will stand that heating indefinitely, although running moderately warm. An 8,200-ohm unit rated at only 2 watts, in which heat is produced at the rate of 5 watts, starts to darken all over in about 1 minute. At 2 minutes it would fry an egg. At 4 minutes the color-code markings are all but illegible, and resistance may rise by about 10%. But there is no smoke, and usually the 2-watt resistor carries. the overload almost indefinitely. Although a resistor which is overheated to a temperature as high as 350° F may not be damaged, heat radiated from it may do a lot of damage to nearby components. Wax-impregnated paper capacitors, and electrolytics too, may be ruined. Should 200 volts get across an 8,200-ohm resistor rated at only 1/2 watt there is blistering, blackening of coding colors and smoking begins within a minute. At 3 minutes the whole unit is black, there is a great deal of smoke and the resistance is dropping sharply. At 4 minutes the resistance is down around 4,000 ohms and, if the voltage holds up, current increases to around 50 ma. Then heat is produced at the rate of 10 watts and the end of the resistor is near. If you find a resistor badly discolored and showing unmistakable signs of having been overheated, measure its resistance. You are likely to find such things as a unit coded for 8,200 ohms measuring something like 3,500 ohms - and causing trouble difficult to locate. Selecting the Right Resistor There is no use installing a new resistor until the contributing cause for the burnout has been determined and removed - we all know that. Neither is there any use putting in a new resistor whose wattage rating is too small for the current it must carry. The chart shows how much current may flow without overheating a resistor of any standard wattage rating, also what wattage rating is needed for any cur-rent flowing in a resistor of any standard value from 10 ohms to 1 megohm. Extra-heavy horizontal lines are for resistances of 10 ohms and multiples of 10 up to 1 megohm. In between are medium-heavy lines for values of each resistor regularly made with 20% tolerance. Light lines are for all values added when tolerance is 10%. All the lines together take in every resistance value regularly used for service replacements. For still other values added in the 5% series, imagine lines approximately midway between those drawn on the chart. Three quick steps allow selecting a resistor of wattage rating just right for the job: not so small that you take chances on a burnout, not so large that you pay for a unit bigger than needed: 1. Locate the horizontal line for resistor ohms. 2. Locate on the bottom scale a vertical line for resistor current. 3. Find the intersection of these lines. Any resistor whose wattage rating is equal to or greater than the value marked on any diagonal line above the intersection will not overheat unless tightly boxed in by surrounding parts. The higher you go in wattage rating, the cooler the resistor will run. But lower on the chart, at lesser wattage ratings, resistor temperature will go up as wattage goes down. Rating vs. Actual Dissipation It seems illogical to many beginners that the number of ohms in a composition resistor is not related to its physical size. They see an 820,000-ohm unit only about one-tenth the bulk of another providing only 82 ohms, or a 22-megohm resistor may have but one-tenth the bulk of a 2.2-ohm unit. It's all a matter of wattage ratings. Another fact not at all illogical, yet sometimes not appreciated, is that there need be no relation at all between the wattage rating of a resistor and actual power in watts changed to heat within the unit. The rating of a resistor specifies only the number of watts or fraction of a watt of power that the unit is designed to get rid of (dissipate) without heating to a temperature which may harm the resistor and nearby circuit components. On the other hand, the number of watts of electric power actually changed into heat depends only on the number of ohms of resistance and on the current in this resistance, nothing else. If you locate any combination of ohms and current on the chart, the diagonal line for watts at that intersection shows how much power will be transformed into heat. How much heat may be produced and safely dissipated depends chiefly on surface area of the resistor and to a minor extent on bulk and kind of material in the insulation. That's why higher wattage ratings require bigger resistors. A resistor retains within itself only a negligible part of the heat produced. The rest must be gotten rid of or dissipated into the surroundings just as fast as produced, or else the resistor would burn up. Heat is dissipated into surrounding air only while the resistor is hotter than the air, and rate of dissipation is proportional to temperature difference. Unfortunately, we cannot get rid of much extra heat by increasing the temperature difference, because we don't want hot resistors. However, we may increase heat dissipation and hold resistor temperature down by increasing the surface area from which heat is dissipated. Composition resistors rated for 1/2-watt dissipation commonly have total surface areas of about 0.20 square inch. A 1-watt unit has a total area of about 0.45 square inch. The 2-watt sizes have about 0.85 square inch. These areas are so closely proportional to wattage ratings that, were all the resistors to run at the same temperature, the 2-watt surface would dissipate about twice as much heat to surrounding air as would the 1-watt size, and the 1-watt surface would dissipate about twice as much heat as the 1/2 watt. If resistor surfaces are to dissipate heat into the surrounding air, they should not be pushed tightly together, shutting off part of the area. Furthermore, crowding prevents heated air from moving away to be replaced by cooler air. Placing a resistor close to chassis metal might appear to be good practice, because heat flows into and through steel better than into and through air, assuming the air to be still. But heated air circulates and floats the heat away, while the chassis doesn't - at least not in present designs. In some recent electronic equipment there has been a trend toward the use of resistors wrapped in a metal band and fastened to the chassis. Reports indicate that this procedure, depending upon the size of the band, may increase the wattage rating of the unit as much as 100%.

Posted March 14, 2022 |

|