How Fuses Work

|

|

Unless you design equipment which requires overcurrent protection to insure the survivability of components within it, you probably do not give much thought to selecting the correct type of fuse. Some people don't even bother to replace a blown fuse with one of exactly the same type - or even the same amperage. We've all heard stories of back in the screw-in fuse panel days when a blown fuse would be replaced by a penny (although that could be a housewife's tale since a penny seems too small to do the job*). The "How Fuses Work" article from a 1961 issue of Radio-Electronics magazine does a good job of reviewing plug, cartridge, and glass fuses, slow-blow, fast-acting, and time delay fuses, high and low voltage fuses, and some specialty configurations like the "grasshopper" fuse. Author Steckler also discusses properties of various fuse types and for which applications they are best suited. How Fuses Work

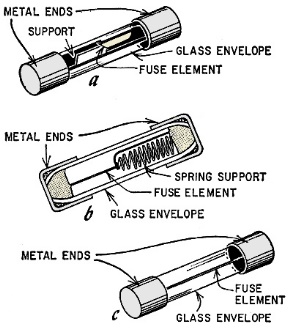

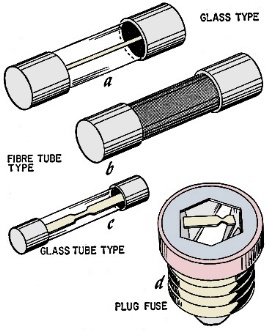

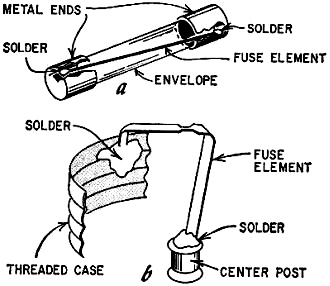

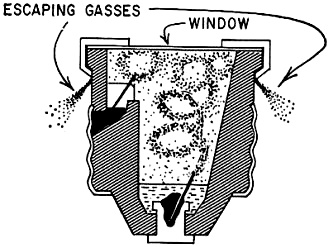

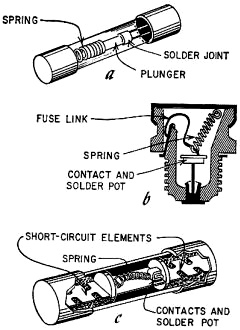

There's more to these tiny equipment savers than you realize Quietly a screen capacitor shorts under continued stress. Current drain increases in the horizontal output tube.. The flyback heats up. And a hair-thin filament inside a glass envelope melts away, restoring safety. This is what a fuse does! Two leads in a line cord short. Sparks fly. Smoke starts to rise. And down in the basement a metal strip literally explodes. The current is cut off. That is what a fuse does! The switch is thrown. Current is applied to a motor that doesn't start. The windings begin to heat up. Insulation starts to smoke. And a little pool of solder gets hot enough to melt, a spring lends its assistance. The circuit is opened and safe. That is what a fuse does! A 10-volt meter is connected to a 300-volt source. The meter pointer heads for the pin at the top of its range. And a microscopic filament gives way. The meter pointer drops back to zero. That is what a fuse does! These are examples of the important thing a fuse does - protects electrical circuits. But how does a fuse protect? What kinds of fuses are in common use? How do they differ? Where do you use them? These are the questions we will try to answer. Pick up a fuse, any fuse. No matter what its shape or size, somewhere on its body are two important pieces of information - a voltage rating and a current rating. Let's see just what these ratings represent. We'll take the current rating first. This is always in amperes or a fraction of an ampere and can range from 1/500 ampere up to any desired value. It simply represents the amount of current the fuse will handle without opening. Greater currents will make the fuse open. Fig. 1a - Instrument fuse with anti-vibration mounting. b - Another type of anti-vibration mounting. c - Larger amperage fuses do not need anti-vibration mountings except in special applications. Fig. 2 - Basic types of fuses: a - Cartridge type with glass envelope and wire fuse link. b - Cartridge type with fibre envelope. c - Cartridge type with ribbon element. d - Plug type with ribbon element. The voltage rating isn't quite so simple. It represents the maximum voltage that can safely be applied to the fuse. A fuse rated at 250 volts can be used in any circuit as long as no more than 250 volts are applied. If more than 250 volts are applied to a 250-volt fuse, several things can happen: - If the voltage is much higher than the fuse rating, it may arc across the fuse. - When a fuse blows, a section of the fusible element literally explodes. But if too high a voltage is applied, this explosive force is greater as a larger section of the fuse link is vaporized. This can cause an under-voltage fuse to explode and send shattered case fragments into anything or anyone close by. The fuse is rated to withstand burnouts at its rated voltage, but will not stand up under excessive voltages. - If a 250-volt 10-ampere fuse is used in a 250-volt circuit and the line shorts, the fuse blows. But no matter how much current goes through the fuse, it will not shatter when it blows. Types of Fuses With some variations there are three basic types of fuses - fast-acting, standard and delay. The fast-acting fuse is designed to protect delicate meters and instruments. It is usually made only in values between 1/500 and 2 amperes. These fuses will carry their full rated current without opening, but a 200% overload will cause them to open in less than 5 seconds. Greater overloads will make them open even faster. For example, a 500% overload will open a fast-acting fuse in 3/100 second. The smaller instrument fuses (1/500- to 1/32-ampere units) have extremely fine elements - some can barely be seen with the naked eye. Therefore they are supported bridge-fashion to protect them against vibration. Sudden shocks would snap such a fine element if it were not supported. The construction of this type of fuse is detailed in Fig. 1-a. In Fig, 1-b another type of anti-vibration mounting is shown. The 1/16- to 2-ampere sizes are illustrated in Fig. 1-c. When we come to the standard types, we find a variety of sizes and shapes. Typical units are shown in Fig. 2. All of these are usually rated to carry 110% of their rated current without opening, yet will open in less than 1 hour if current goes up to 135% of the rated value. Again, greater overloads will blow the fuse much sooner, within fractions of a second in some instances. The two major types of standard fuses are plug types (like those you use in your fuse box at home) and cartridge types that have either a glass, fiber or Bakelite case. The elements are either a single wire or a flat ribbon (Fig, 2). In cartridge types this element is supported at each end (Fig. 3-a), while in plug types the mounting is a little more complicated (Fig, 3-b). The amazing things about these fuses are the things not generally known. For example, let's take a plug type fuse that has just been subjected to a severe overload. The intense heat caused by the excessive current turns the fuse link into white hot gases under tremendous pressure. Naturally, there must be a safe way for these gases to escape. One manufacturer handles this problem by making the top cap of its fuse act as a valve (Fig. 4). The hot gases spread out along the mica window in the top of the fuse and escape through tiny notches under the edge of the top cap. This cools the gases and allows them to discharge safely. Now to one of the most interesting of all, the slow-blow or delay fuse. The thing that makes these units so fascinating is that they work in a variety of ways although they all do the same thing. Basically, a delay fuse will tolerate a certain amount of overload and do so intentionally. However, if the overload continues for an excessive period of time, the fuse opens. Also, a delay fuse will blow almost instantly if the overload is many times too great. These fuses are often used where motors (air conditioners, refrigerators, etc.) are in circuit, since such devices often draw starting currents several times greater than their running current. For example, a 7.5-ampere air conditioner needs a 15- to 20-ampere standard fuse to tolerate its tremendous starting current. But if the motor didn't start, it would draw enough current to burn out but not enough to open the fuse. Fig. 3 - Internal assembly of fuses. a - cartridge type; b - plug type. Fig. 4 - When this type of plug fuse blows, gas escapes through vents around the cap. Fig. 5 - Construction of various types of slow-blow and time-lag fuses.

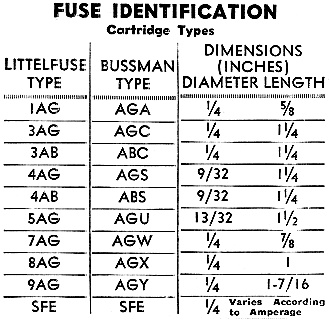

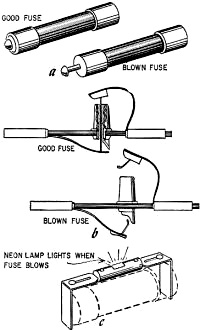

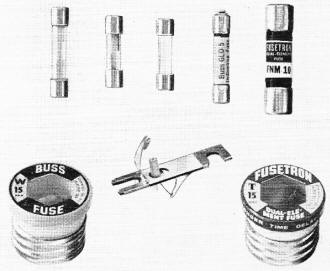

Fuse identification table. Five types of cartridge fuses made by Littelfuse. Fig. 6 - Special types of fuses: a - Pin comes out end of indicating fuse when it blows. b - Grasshopper fuse springs apart, gives positive action. c - Another type of indicating fuse. Bussmann makes this assortment of fuses. When you use a slow-blow fuse, however, a 10-ampere unit will take the starting surge of 15 to 20 amperes without blowing but, if this surge doesn't taper off within a reasonable time, the fuse will blow, This could happen if a starting capacitor shorted. In some of the older TV receivers, slow-blow fuses were used to protect the high-voltage circuits. These sets developed transient pulses that would blow a standard fuse. By using a slow-blow fuse, however, the set manufacturer got a delay that was long enough to keep the fuse from blowing because of transients, as well as protection against severe shorts. So in a TV receiver, never replace a slow-blow fuse with a standard type or you'll probably find yourself coming back again because of a blown fuse, even when there is no trouble in the circuit. Conversely, if you are having trouble with standard fuses blowing, don't substitute a slow-blow fuse. These will not protect the circuit properly and could result in a flyback burnout because a shorted damper tube didn't blow the fuse in time to save the flyback. Now, we've seen where slow-blow fuses are used, and why. But just how do slow-blow fuses work? Three kinds of slow-blow fuses are shown in Fig. 5. The first (Fig. 5-a) is a cartridge type. An overload heats up the solder that holds the contacts together. If the overload doesn't last too long, the solder cools and everything returns to normal. However, if the overload doesn't clear up, the solder melts and the spring pulls the contacts apart, opening the circuit. If there had been a short in the circuit, the fuse element would have vaporized - just as it would in standard fuses - before the solder even got a chance to warm up. The fuses shown in Fig. 5-b and -c work in the same fashion; the only difference is in their design. Fig. 5-b shows a plug type fuse and Fig. 5-c is what is termed a time-lag fuse. Such a unit is designed to give a long time delay for special applications. Special Types Another group of interesting fuses are the indicating types. These units let you know when they have burned out or opened. In some (Fig, 6-a), a little plunger comes out the end, or the top (Fig. 6-b). Other devices can be added to these fuses so that, when they open, the plunger will close a switch to turn a pilot or warning lamp on or off. Or, as one manufacturer is doing simple attachments may be added to almost any type of fuse, to light when the fuse blows. These units are shown in Fig. 6-c. Indicating fuses are most often found where a large number of fuses are mounted on a single panel. Here they become necessary if a blown fuse is to be found easily and quickly, Therefore, they are commonly used in industrial and military applications. Still another special type fuse is the grasshopper. It has already been shown in Fig. 6-b where its application as an indicating fuse was shown. But even more important is its action when it blows. The two leaflike elements spring apart, giving a quick-acting fuse that is practical for high voltages. The spring action pulls the broken ends of the fuse so far apart that no arcing can occur across the gap. Another type of fuse is the fusable resistor found in many recent-model TV receivers. This unit is a wirewound resistor with some specific ohm age rating - somewhere between 5 and 13 ohms. It provides two types of protection. It acts as a series resistance that protects rectifiers in the set against sudden voltage surges, and it acts as a slow-blow fuse for overloads. The unit is actually a wirewound resistor, but one that will burn out if the set draws excessive current. A rather different type fuse is the chemical fuse. To date it is used by only one manufacturer (RCA), to protect the B-plus circuit of TV receivers. It looks like a standard cartridge fuse in size and shape, but instead of a glass cylinder surrounding the fuse element, there is a ceramic jacket. The fuse element itself is a metal wire covered with a special chemical coating. When it is in the B-plus circuit of a TV receiver, it passes current just like any other fuse. If the damper cathode arcs over momentarily, the short surge starts to heat up the wire in the fuse but doesn't last long enough to have any effect. (This same transient would burn out a standard 1/4-amp fuse.) However, if there is a short that exceeds the current rating of the fuse and lasts longer than a few instants, the wire in the fuse gets hot enough to set off the chemical coating and the fuse element disintegrates. (This action is much faster than that of a slow-blow fuse and therefore provides greater protection.) Fuse Identification There are two major manufacturers of fuses in the US today - Littelfuse and Bussmann. These companies use different codes to identify their fuses. For the technician who may run into a Littelfuse and has only Bussmann replacements, or the man who runs into a Bussmann fuse and has only Littelfuse replacements, we have listed both makes in a table that shows equivalent units. When replacing fuses, an important factor is physical size. In automotive fuses, for example, only one amperage fuse will fit in a particular fuse holder since each amperage fuse is a different length - the higher the current rating, the longer the fuse. However, for other applications, many fuses will all have the same length. For example, in the 3AG series, all fuses are the same length, no matter what current rating they have. Also, the 20-amp auto fuse is the same length as all the 3AG fuses. Therefore, when replacing fuses, always be sure that you are using a replacement whose voltage and current ratings are identical to those of the fuse that blew. And remember, if a fuse keeps blowing, something is drawing too much current - don't replace the blown fuse with one that has a higher current rating. It may not blow, but your wiring may overheat and start a fire. Or in a TV receiver you'll lose a $10 flyback transformer instead of a 25-cent fuse. So where do we use the many types of fuses we have surveyed? Quick-acting units go into that expensive voltmeter or other delicate test instrument that small overloads may damage. The slow-blow types go wherever short surge currents are normal and where a standard fuse would blow, even though there is no fault in the circuit. And standard fuses are used about everywhere else. But to play it safe, whenever you replace a fuse, use one that has identical ratings to the one that blew and you can't go wrong. You can track down a dead short with an ohmmeter; a slight overload will call for checking the parts that draw current off the line by removing them one at a time. When the current drops to normal upon removing a particular part, you know that it is the defective one. So don't take that little glass tube or screw-in device for granted. Use it properly and it can be a lifesaver. Thanks to Bussmann Manufacturing Div., Littelfuse Inc., and the Sight-master Corp., for supplying much information. Here's what ChatGPT said when asked about a penny in a fuse socket:

Posted August 1, 2023 |

|

By Larry Steckler, Associate Editor

By Larry Steckler, Associate Editor