Magnetic Recording - Recorder Design

|

|

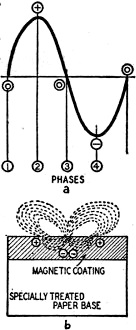

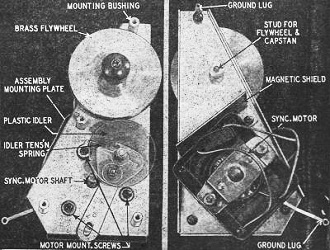

In most instances the method and materials have changed over the years, but fundamental principles of writing and reading data to and from magnetic media are the same today as when this article was written in 1947. If you find that your lexicon of technical jargon lacks terms such as coercivity and remanence, then you might want to invest a few moments reading this short article that appeared in Radio-Craft magazine. I realize most regular RF Cafe visitors won't be interested, but hopefully someone, somewhere, searching for this information will now be able to find it. Thanks for your indulgence. Part I, "A Modern View of Permanent Magnet Theory," appeared in the October 1947 issue and Part II, "Benefits of Tape Recording," appeared in the November 1947 issue. Magnetic Recording - Recorder Design Part III of a series, the first two parts of which were headed Magnetism. This part deals with recorder design. Next will be construction of a practical tape recorder. By A.C. Shaney* *Chief Engineer, Amplifier Corp. of America. Fig. 1 - The Mail-A-Voice uses magnetic discs. Courtesy Brush Development Corp. Fig. 2 - This machine records 12,500 cycles. Courtesy Amplifier Corp. of America One of the most important elements in any magnetic recording process is the magnetic carrier (the material upon which the magnetic modulations are impressed or recorded). Magnetic carriers which have been used successfully to date include metallic ribbon and wire, nonmagnetic ribbon and wire plated with special magnetic coatings, and magnetically coated and impregnated paper and plastic tapes. Early experimenters successfully applied magnetic modulation to a magnetically coated cylinder. A magnetic recorder and play-back device which is now available (Fig. 1) utilizes magnetically coated thin paper discs. This list is merely suggestive and by no means exhausts all the possibilities. For example, it should be both economical and practical to coat or impregnate magnetically plastic or cotton fiber thread or other artificial fiber. The actual magnetic properties of the magnetic carrier determine, to a considerable degree, the overall performance characteristics of the recording and playback system. They also play an important determinative factor in the design of all other essential elements and auxiliary components used in both the magnetic recording and playback processes. Many early and highly qualified technicians experimenting with magnetic recording failed to evaluate properly all effects which were normal functions of carrier characteristics, and as a result came to erroneous conclusions. For example" it was believed (during 1932, that it was necessary to run a magnetic carrier at a speed of 393.7 inches per second to obtain a frequency response up to 5,000 cycles. As a result, it was fallaciously concluded that the necessity for the high speed "restricts the application of this recording method to reproduction in the speech range." Today in contrast, a commercially available unit (Fig. 2) is capable of recording and reproducing up to 5,000 cycles with a carrier speed of 4 inches per second - a reduction in carrier speed of nearly 100 times without affecting frequency response, attaining, at the same time, many other desirable improvements in noise reduction, increased dynamic range, and lower distortion! Nine thousand cycles has been recorded and played back at a carrier speed of 7 1/2 inches per second, and 12,500 cycles has been attained at a tape speed of 15 inches per second. (Magnetically coated paper tape was used to attain the indicated results.) The rate of progress in the art of magnetic recording can be measured by the carrier speed of the magnetic medium employed. Slow speeds (with desired frequency response) indicate greater economy of the magnetic medium and longer playing time for a given length and cost of material Progress in this respect has been little short of phenomenal. For example, in 1932 118,000 feet of wire was required for a 1-hour program reproducing up to 5,000 cycles. In 1943 the same program quality and duration could be maintained with 11,000 feet of wire. By 1946, it took only 1,250 feet of coated tape to duplicate the same program! All students of radio have been correctly impressed with the idea that the rate of radio wave propagation (radio carrier speed) is constant (300,000,000 meters per second). As a result, it is simple to calculate wave length - the distance through which current will travel within one cycle - from the following well-known formula. λ = k/f when λ = wavelength, f = frequency, and k = carrier speed (186,000 miles per second or 300,000,000 meters per second). In magnetic recording, the carrier speed is not a fixed and unvarying constant. In fact, as previously explained, there is a strong tendency to continually decrease its speed without affecting over-all response. As a result, the magnetically recorded wavelength of a given frequency will be a function of the magnetic carrier speed and can be found from this simple expression: λ = s/f when s = magnetic carrier lineal speed. Thus a 5,000-cycle signal when magnetically recorded on a tape running 7 1/2 inches per second will have a wave length of 1.5 thousandths of an inch. Similarly, a 5,000-cycle signal recorded at a carrier speed of 4 inches will have a wave length of 8 ten-thousandths of an inch. When it is realized that each complete wave length has 4 phases (see Fig. 3), evidently each phase of 8 ten-thousandths of an inch wave length will be only 2 ten-thousandths of an inch long (approximately 5 microns). We begin to get an idea of the minute dimensions involved in attempting high-frequency magnetic recording on slow-moving media. Carrier speed stability Fig. 3-a - Four phases of sine wave. 3-b - Enlarged cross section of paper tape to show internal and external magnetic flux lines. A casual examination of the formula (2) relating wave length to speed and frequency indicates that if the magnetic wave length is constant (and it is, if a fixed frequency has been recorded at a constant speed) the reproduced frequency will be directly proportional to lineal speed. If the lineal speed of the magnetic medium should vary for any reason whatsoever, the reproduced frequency will similarly vary. This produces a noticeable variation of frequency when sustained tones are reproduced and resembles the turntable "wow" common to disc recording and reproducing systems which do not employ absolutely constant-speed turntables. To minimize any instantaneous speed variations, it is important to avoid eccentricities in any of the driving members involved in pulling the magnetic medium past the playback head. A correctly designed flywheel should be used to smooth out cyclic pulls common to "constant speed" synchronous "motors. A correctly designed capstan drive and flywheel is illustrated in Fig. 4. The load applied to the driving motor should be constant. Bent reels or spools which scrape either the recording medium or adjacent surfaces are the most common cause of frequency variations in a properly designed mechanism. An idea of the desired constancy of linear speed may be gained from the already established data which indicates that an average listener can detect frequency deviations in the order of 3/10 of 1% (3 parts in 1,000) within the frequency range of 400 to 5,000 cycles. Therefore, instantaneous lineal speed variations should be no greater than ± 0.1% (which allows a variation of 2 parts in 1,000). Magnetic carrier compliance Early experimenters who attempted to increase the high-frequency response of magnetic recording systems by increasing wire speeds were bothered by pronounced variations in signal level mainly caused by wire "flutter." A stiff wire travelling at high speed will tend to assume some natural period of vibration dependent upon its thickness, tautness, and the distance between its supports. Flutter (a transverse vibration) produces a minute frequency variation "wow" (because a slight change in lineal speed takes place), but more important, it introduces a varying pressure against the recording head which in turn changes the air gaps between the magnetic medium and its pickup head. These minute variations produce appreciable high-frequency level fluctuations characteristic of flutter. Steel tapes travelling at high speeds are similarly afflicted. Paper and plastic tapes, - because of their increased compliance and slow speeds - are more easily passed by the pickup head with negligible flutter effects. On the other hand, their increased compliance makes it necessary to use pressure fingers to keep the tape pressed, at a relatively fixed pressure, against the recording and playback heads. Dimensional stability When discussing lineal speed stability and its relation to "wow," it was assumed that a magnetically recorded fixed-frequency signal would maintain a fixed wave length. This is true as long as the wire or tape doesn't stretch. If stretching does take place, because of temperature and humidity changes between the recording and playback process (and it may, because of the tensions or pull applied to the medium during recording, rewinding, and playback), we then have a new variable to consider. A simple transposition of formula (2) produces s = λf (3) which indicates that if the speed remains constant, the reproduced frequency is inversely proportional to wave length. In other words, if the magnetic medium stretches the wave length increases and reproduced frequency decreases! This effect will not be noticeable as long as the "stretch" or dimensional stability is within ± 0.1%. Plastic tapes and thin wires naturally will have some tendency to stretch. The paper base used for coated tape is made of carefully selected material and treated by prestretching for improved dimensional stability. As expected, one of the most important elements in magnetic recording and playback is the actual magnetic and physical properties of the magnetic carrier. In a magnetic coated medium, the coating itself, and not the base, plays the most important role in the process. Some of the more critical factors which determine the efficiency, noise, response, constancy of output, overload characteristics, and velocity of the carrier include it coercivity, remanence, particle size, binder, dispersion, chemical composition, surface smoothness, and coating thickness. Each of these characteristics has a profound influence upon the over-all characteristics and performance of the recording and playback system. A brief. discussion of these factors together with the design details of a suitable magnetic recording amplifier will be covered in the next issue. Two transpositional errors occurred in the October installment of this series. In comparing the conductivity of electric and magnetic circuits, the formulae should have been: G = I/E μ = B/H G = conductance in mhos E = e.m.f. (volts) I = current (amps) μ = permeability H = magnetomotive force (oersteds) B = magnetic flux (gausses)

Posted April 8, 2022 |

|