Winding Your Own Output Transformers

|

|

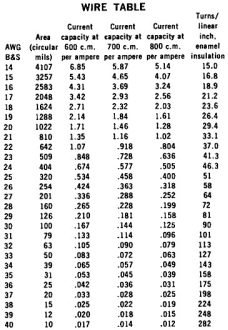

Even if you no longer - or never did - have the need to wind your own audio frequency output impedance matching transformers, this article from a 1970 issue of Popular Electronics magazine provides good insight into the factors necessary for consideration when doing so. One particularly nice feature here is that power handling is taken into account, including wire size to use for the primary and secondary (or multiple outputs). At audio frequencies, where the transformer is driving speakers with typical impedances of 4, 8, or 16 ohms, you do not need to worry too much about parasitic capacitance and inductance. The basic equations do a pretty good job of predicting performance. Author Ed Francis explains how to modify a junk-box laminated core transformer to work, as well as providing a table of enameled wire size ampacities and turns per linear inch. An example of how to perform all the steps is given. For Improved Matching and Power Handling

Circuits involving solid-state components frequently require "non-standard" audio output transformers. This article describes simplified methods of calculating the primary/secondary ratios, wire sizes, and numbers of turns for low-impedance matching transformers wound on "salvaged" cores. Project Builders and experimenters occasionally need a small impedance matching audio transformer with an uncommon impedance ratio. When such a transformer is specially wound, its cost is usually prohibitively high compared to the total cost of the project in which it is to be used. However, with a few calculations and a little work on your part, you can duplicate many unusual transformers or and special audio coupling or matching transformer to suit your needs. The techniques prescribed in this article are limited to transformers of average size and low-to-medium impedance. It is impractical to duplicate subminiature transformers that normally cost only $1 or less and high-impedance transformers that require many turns of very fine wire. Throughout tins article, you will find the term "volt amperes" (VA) used in the same manner that "watts" is used for power. This usage involves an assumption which is not quite true. However, for this type of work, if you accept the assumption that the two are equal, the results will be acceptable. Calculations involved in designing an audio transformer are covered by the nine steps outlined in the box on page 81. To see how these steps work, let's design a typical transformer. Assume that a transistor output transformer with a 130-ohm primary and a 4/8/16-ohm secondary is needed to match the output of an RCA CA3020 IC to a loudspeaker. By referring to the mail-order catalogs, we find that the full output of the IC is 0.5 watt. The nearest thing you can find in the catalog is a 125-ohm center-tapped transformer rated at 300mW. This transformer could be used, but, you can make one that will be. just as good and design it for a full watt if space and weight requirements permit.

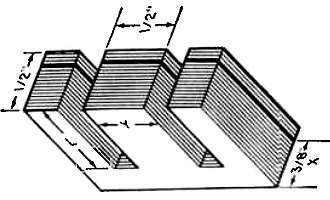

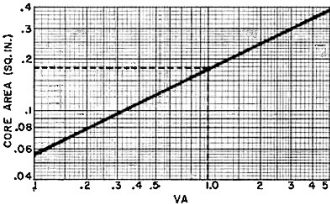

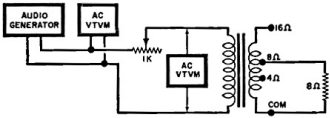

Fig. 1 - Calculate X dimension needed to provide core area when multiplied with Y dimension; then, as indicated by heavy lines, remove required number of metal laminations. Fig. 2 - Lengthy mathematical computations for determining the transformer core area can be avoided with the aid of the graph shown here.

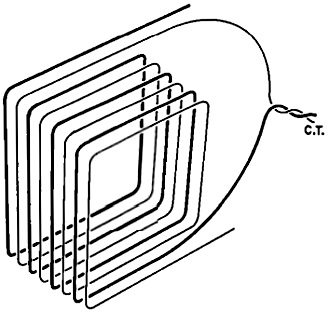

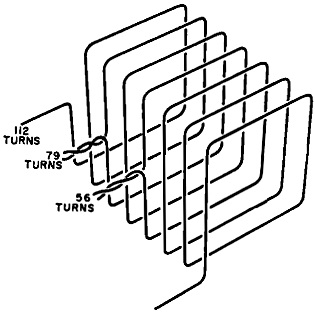

Fig. 3 - Bifilar winding technique precisely locates center-tap. Center-tap is derived by twisting together opposite ends of winding. Wire Table

Fig. 4 - Individual taps are obtained by twisting short pigtails from continuous length of wire. Attach stranded wire leads to pigtails. Fig. 5 - Although not really necessary if you followed all steps carefully, the finished transformer can be tested as shown in drawing. First calculate the core area required. Note, however, that tile core area applies only to the cross-sectional area of the core's center leg as shown in Fig. 1. Referring to Fig. 2, we find that the graph shows an approximate core area of 0.18 sq. in. will snit our requirements. (We can use an approximation since the actual core area is not too critical.) Determine the turns ratio from the impedance ratio. Since we know the primary and lowest secondary impedances to be used, plug 130 and 4 into the equation: Ratio = the square root of (130/4):1 = 5.7:1. Hence, the actual turns ratio required shows 5.7 turns in the primary winding for every turn in the secondary winding. Next, determine the d.c. voltage to be applied to the transformer's primary. In this ease, we desire 9-volt operation. The CA3020 employs a push-pull. output. So, bear in mind that an 18-volt figure must be used in all primary calculations. Calculate the wire size needed for the primary winding. Since we have decided to design the transformer to handle 1 watt of power, let us first determine how much current will be handled by the primary: I = (VA/Vcc) = 1/9 = 0.111 A. Now, because of the push-pull division of the current, we divide the primary current by two for determining the wire size; this gives us 55 mA in each half of the primary winding. If 700 circular mils/ampere is desired, refer to the Wire Table (column four) on page 80, and locate the current at or greater than 55 mA. Column one shows that #34 wire will safely handle 57 mA, the nearest figure to 55 mA. This size is quite small and difficult to work with, so choose #28 wire for ease of winding. We will have to make some assumptions now in determining the number of primary turns to be used. For this calculation, we will use 2Vcc, or 18 volts, and an area of 0.18 sq. in. for our 1-watt transformer. The frequency we will arbitrarily settle on as being 100 Hz. For flux density BM in gauss/sq. in., any figure between 40,000 and 90,000 can be used; we'll settle on 70,000 to be conservative: Primary Turns = 2Vcc x 108 / (4.44 x Ax f x BM) = 18 x 108 / [4.44 x (0.18) x (100) x (70,000)] = 321 so, 320 turns will be close enough. Having calculated the number of primary turns, we use the turns ratio formula to calculate the number of secondary turns needed. This is a step-down-type transformer, so we divide the number of primary turns by t to turns ratio: Secondary Turns = Primary Turns / Turns Ratio = 320 / 5.7 = 56 turns. Secondary wire size is determined by the current ratio method. Secondary current is equal to the primary current multiplied by the turns ratio: 0.111 x 5.7 = 0.64 A. The secondary wire size is determined by the same method as used for the primary. At 700 circular arils/ampere, the Wire Table indicates a 577 mA current capacity for #24 and 728 mA for #23 wire. Since 640 mA is about midway between the two sizes, we will settle on #23 wire. Finally, the 8-and 16-ohm taps must be calculated. Again, refer to the turns ratio formula, and determine the turns ratio for 8 and 16 ohms separately. Then use these ratios with the primary turns to determine the exact number of turns required for each impedance: 16-ohm ratio = the square root of (130/16):1 = 2.86:1; 8-ohm ratio = the square root of (130/8):1 = 4.04:1. Secondary turns = 320/2.86 = 112 turns for the 16-ohm ratio; Secondary turns = 320/4.04 = 79 turns for the 8-ohm ratio. Hence, the composite secondary will consist of 112 turns of wire with taps at the 56th and 79th turns. Now that we have all of the design parameters, we can proceed to assembling our special-purpose transformer. Assembling the transformer from the design parameters derived from the above procedure is easy. We know that the core area must be about 0.18 sq. in. The simplest and least expensive way of obtaining a suitable core is to salvage an old audio output transformer. Many such transformers have a core area of 0.25 sq. in. If about a quarter of the laminations are removed, approximately the correct dimensions will be obtained (about 0.185 sq. in.). Disassemble the salvaged transformer, and remove and discard the windings, but reserve the plastic winding bobbins if it has one. It no bobbin is available, you can make one from an index card or heavy waxed (butcher's) paper. This bobbin should easily slide over the core leg and be a little shorter than the center leg of the laminations. Slide the bobbin onto a length of wood to serve as a winding handle. Then begin winding the primary turns onto the bobbin, starting and ending along the 1/2" side of the bobbin to avoid having the ends exit from the core "windows" when the bobbin is in place. Ordinary "scatter" winding is acceptable in most cases; but if space is limited, you might have to close-wind the turns. Our hypothetical transformer has a further complication: The primary winding is center-tapped. It must be wound so that both sides of the winding are balanced. To do this we will use the "bifilar" winding method shown in Fig. 3. For our 320-turn primary winding, we wind two wires onto the bobbin simultaneously, side by side, until there are 160 double turns on the bobbin. Then to complete the bifilar winding, we connect one end of one wire to the opposite end of the other wire and solder on a 5" length of stranded hookup wire to make the center tap. Two more stranded wires soldered to the free ends of the primary windings complete the primary assembly. Color code the wires so that the center tap is easily identifiable. Make sure that each soldered connection is well insulated from the others; then wrap a layer or two of plastic tape over the windings. Now wind the secondary turns onto the bobbin. Count tile turns as you go, and make a pig-tail tap leads at the 56th and 79th turns for the 4- and 8-ohm taps (see Fig. 4). Use color coded stranded hookup wires for the winding ends and taps so that each can be easily identifiable. Again, make s ire that the solder connections are well insulated from each other, and wrap a layer or two of electrical tape over the assembly to prevent the windings from unraveling. Slip the bobbin assembly off the winding handle. Orient the primary leads to one side and the secondary leads to the other side of the bobbin. Then slip the bobbin onto the center leg of the transformer core laminations. Assemble the transformer. Testing the completed transformer is not really necessary if you exercised care during assembly and followed each step exactly as described. However, if you want to be on the safe side, von can test the transformer with the aid of an audio signal generator, two ac VTVM's or FET VOM's, an 8-ohm load resistor, and a 1000-ohm potentiometer as shown in Fig. 5. Set the generator's amplitude control for an output of several volts at 1000 Hz. Adjust the potentiometer for mini-mum resistance so that both meters have an identical reading. Now, increase the resistance of the potentiometer until meter #2 indicates exactly, one half its original indication while making sure that meter #1 remains at the original voltage setting. Since changing the resistance of the potentiometer decreases the load on the audio generator, meter #1 will indicate an increase in voltage. Simply reduce the generator's output level to return meter #1 to the original voltage setting. After jockeying back and forth between the generator's amplitude control and the potentiometer a few times, you should be able to arrive at settings where meter #1 indicates the original voltage and meter #2 indicates exactly half of its original voltage. When this occurs, remove the potentiometer front the circuit without upsetting its final setting and measure its resistance. This resistance should be equal (or as near as possible) lo the transformer's input impedance, or 130 ohms. However, if the transformer is loaded with an incorrect impedance (say, the 8-ohm load resistor connected acres the 4-or 16-ohn output leads), it will reflect an incorrect impedance into the primary. As a matter of tact, if you use a 3.2-ohm speaker on the 4-ohm transformer output, a primary, impedance somewhat lower than that for which the transformer was designed will be reflected. But if you plan to rise such a speaker with the transformer, yon could easily have plugged into the equations the 3.2-ohm figure for the 4-olun figure. 9-Step Audio Transformer Design Example In approaching something like the design of your own special-purpose audio matching or output transformer, you should use a practical, realistic procedure. The nine steps outlined here are set up so that you will not overlook time and work -saving steps and will lead you from start to finish without a lot of messy mathematical calculations. Step (1). Refer to the catalogs for all available data (such as primary and secondary impedances and power and voltage ratings) concerning the transformer needed. Step (2). Determine the transformer core area; from the transformer power rating (VA), area is equal to the square root of VA divided by 5.58. A quicker method is to refer to the graph in Fig. 2. Read up from the selected volt-amperes figure to the diagonal line, project to the left and read the core area in square inches. Step (3). Calculate the turns ratio. From the impedance ratio, the turns ratio is equal to the square root of (Z1/Z2), where Z1 is the larger and Z2 the smaller impedances. Step (4). Determine the voltage for which the transformer primary is to be used. For single -ended operation, use supply voltage Vcc; for push-pull operation use 2Vcc. Step (5). Compute the size of the wire needed for the primary turns. Using the transformer power rating and the d.c. operating voltage (Vcc), primary current equals VA/Vcc. For audio service, a minimum of 600 circular mils/ampere is recommended; winding space permitting, it would be better to figure on using 700-1000 circular mils/ampere. A center. tapped primary would have only half of the total current flowing through each half of the winding at any one time, so the metric area can be reduced by half. Step (6). Calculate the number of primary turns needed: Primary Turns = Vcc x 108 / [4.44 x (A) x (f) x (BM)], where Vcc is supply voltage; A is core area in square inches; f is the lowest frequency to be passed without loss; and BM is flux density in gauss/square inch. Step (7). Determine the number of secondary turns required. If the transformer is to be an impedance -step up type, multiply the turns ratio by the number of primary turns calculated; if step-down, divide the primary turns by the turns ratio. Step (8). Calculate the secondary wire size by the turns ratio method. Current transfer is inversely proportional to the turns ratio. Hence, if the transformer is a 10:1 step-down type, the secondary should be capable of handling ten times as much current as the primary. Once the current capacity is determined, you can refer to the Wire Table to find the smallest diameter wire that will suit your needs. It is, however, advisable to use the largest practical size wire to obviate a large d.c. voltage drop in the windings. Step (9). If the center tap is required, use the "bifilar" method of winding (see text). For multi-impedance outputs, recalculate the turns ratios, secondary currents, etc., for each output impedance.

Posted September 6, 2022 |

|

By Ed Francis

By Ed Francis