Heat Without Flame

|

|

Electric induction heating has been used in manufacturing processes since shortly after Benjamin Franklin invented electricity. Of course I jest about Franklin; he didn't invent electricity but discovered that lightning was a form of electrical discharge. One of the most energy-consuming forms of induction heating is that used by Alcoa for smelting aluminum. Beyond that are many thousands of processes ranging from forming, tempering, and joining metal parts to cooking food and curing adhesives. Both Tocco and Ajax-Northrup, now Ajax Tocco, brands of equipment are featured in this 1955 article which appeared in Popular Electronics magazine. Some processes work by directly inducing a high current in the primary target object - usually metallic - being treated. Others induce the current in a secondary object like a metallic cooking container which then warms the target object through heat conduction process. Ajax Tocco has a pretty awesome video providing an overview of their capabilities - including some applications you probably never knew were performed via induction heating. They also have a slew of videos for individual processes. You might find interesting the first-person experience with the hazards of industrial heating processes using RF sources - "Out of Order: Tracking Down a Mystery Signal." Heat Without Flame Current following through a conductor sets up magnetic field (a) which may be concentrated by bending the conductor to form a loop (b), or by providing a core of magnetic material (c). In the first part of this two-part story, the Editors of Popular Electronics report on modern advances in the scientific use of induction heaters by industry. Without heat, man never could have smelted metals and built the great civilization of today on its foundation of steel, copper, tin, and other metals. For many, many centuries, heat was intimately associated with fire, but in comparatively modern times, the development and use of electrical power has led to heat without fire. When an electric voltage is applied to a conductor, the conductor offers a resistance to the flow of current and the current, in overcoming this resistance, produces heat. The amount of heat produced depends on both the resistance of the material and the amount of current. However, even with the development of electric heaters, heat had to be produced before it could be applied. But today in factories and plants all over the world heat is being used without initial generation. Instead, the heat is generated within the material being processed. Two kinds of heaters are in use: induction heaters, used with conductors such as iron and steel; and dielectric heaters, used with insulators, such as wood and plastics. Induction heaters will be discussed now. In a subsequent issue of Popular Electronics dielectric heaters will be covered. Principles of Induction Heating When electric current flows through a conductor, heat is produced. In addition, a magnetic field is set up around the conductor. This magnetic field may be concentrated by bending the conductor in loops to form a coil and by providing a core of magnetic material. The intensity of the magnetic field depends on three factors: the amount of current in the conductor; the number of turns in the coil; and the type of core material used.

A magnetic field will couple the primary and secondary windings in a transformer.

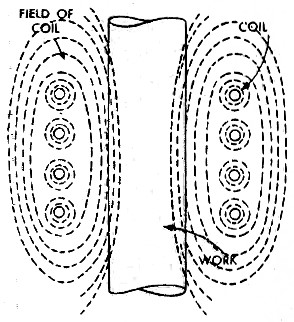

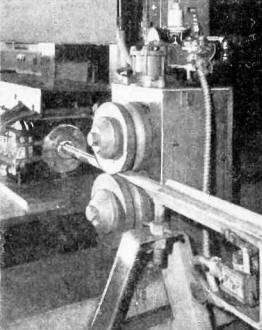

The effect of the electromagnetic field produced by loading the coil is shown above. If an alternating current flows through the conductor, a changing magnetic field will be produced which will build up to maximum intensity, collapse, and build up to maximum intensity again, but with reversed polarity. If this varying magnetic field is brought near a second conductor, a current will be induced in the second conductor. This principle is used in transformers. Two or more coils are placed fairly close together. An alternating current is passed through the first conductor, or primary winding, and this current produces a magnetic field which induces currents in the secondary windings. When the primary coil surrounds a relatively solid conducting mass, the induced currents are not channeled as in a transformer, but flow like eddies in many directions. Since the solid mass acts like a short circuit, these eddy currents may be large, causing considerable heat to be generated within the mass. It is on this "transformer" action that induction heating is based. Where the core is a magnetic material, such as iron or steel, it is rapidly magnetized, demagnetized, and remagnetized in the opposite direction. The individual molecules change position with each magnetization change, resulting in considerable molecular "friction" and producing additional heat. The molecular "friction" which keeps the molecules of the material from changing position easily is known as hysteresis. In a conventional transformer, the heat produced by eddy currents and hysteresis represents a power loss. Although induction heating equipment is designed to produce such heat in the material being processed, iron core power transformers are designed to keep such heating to a minimum. To accomplish this, the cores of such transformers are made of thin laminations of steel rather than a solid piece. The thin laminations have a comparatively high resistance, keeping eddy current losses at a minimum. As the frequency of the alternating current is increased, the induced currents tend to flow nearer the surface of the conductor. At fairly high frequencies, the induced currents may be concentrated in a very thin "skin" right at the surface. This is known as skin effect. Since heating depends to a large extent on these induced currents, induction heating is especially valuable in heating only the surface of a piece of work, such as a bearing or a gear face. Types of Induction Heaters Commercial induction heaters consist of two major components: the alternating current power source or "generator" and the work coil which is coupled to the load and serves to change the alternating current to a varying magnetic field. The frequencies used for induction heating range from 25 cycles per second to several megacycles. Where commercial line frequencies (25-60 cps) are involved, electrical energy may be obtained directly from the power lines. But where higher frequencies are required, there are three basic types of "generators" widely used by modern industry: the motor-generator set; the spark-gap oscillator; and the vacuum-tube oscillator. The Motor-Generator Set: A motor-generator set is an electric motor driving a high frequency generator. This Tocco heating station with inductor and fixture is used for brazing hydraulic cylinders and cylinder cap assemblies. Due to practical limitations on generator size and speed, output frequencies of 1000, 3000, and 10,000 cps are the most popular and the majority of commercial induction heater motor-generators are designed to supply power at one of these frequencies. Power output for a single unit may range from less than 10 kw. to more than 1200 kw. Where higher powers are required, a "bank" of individual units may be used. Most commercial units have efficiencies running from 60 to 90 per-cent. Motor-generator sets are used where large amounts of relatively low frequency power are required for such applications as forging, melting, and deep hardening. The Spark-Gap Oscillator: The first high frequency generators used for induction heating were spark-gap oscillators. Dr. Edwin F. Northrup, one of the pioneers in the induction heating field, did most of his work in the early 1900's, when spark-gap oscillators were widely used for "wireless" communications. Although vacuum tube oscillators have replaced spark-gap units in the communications field, spark-gap oscillators are still extensively used by industry. In a spark-gap oscillator an inductance coil is connected in series with a spark-gap and both are connected across a large capacitor. A high a.c. voltage is applied to the capacitor. Normally, the spark-gap is non-conducting and acts as an open circuit. The voltage charge of the capacitor builds up to near its peak value, at which point the gap breaks down and effectively closes the connection between coil and capacitor, forming an oscillatory tuned circuit. Very heavy currents surge back and forth between the coil and capacitor, as the capacitor is alternately charged and discharged, at a frequency determined by the inductance and capacity values of the components. With such current surge, the amplitude drops slightly, as energy is dissipated in the circuit and in the load, until there is no longer sufficient energy to maintain the spark. At this point the spark dies out and the gap again acts like an open circuit. The output of a spark -gap oscillator is thus a series of high frequency pulses. Spark-gap oscillators are generally designed to operate in the frequency range of from 20 to 500 kc. Most manufacturers rate them by power input rather than by power output. Standard spark-gap oscillators are made with power ratings up to about 40 kw., and down to about 2 kw. With a wide frequency range and low to moderate output powers, spark-gap oscillators are well suited to such applications as melting and forging small to moderate sized pieces. Feed rolls push bar stock through a set of Tocco induction coils which heat the stock to a temperature of about 2350 degrees F. This huge Ajax-Northrup heater coil is used for the hot pressing of carbide steels. Portable units are also available for this purpose. The Vacuum-Tube Oscillator: Except for the power ratings, the oscillator circuits are similar to the circuits used in radio transmitters. But there is a difference between a high-power induction heater and a high-power radio transmitter. Broadcast transmitters generally employ a low to moderate power oscillator, followed by several stages of amplification. Induction heaters, or the other hand, use high power oscillators directly. The plate (output) and grid (input) circuits of a vacuum-tube amplifier are coupled so that part of the output energy is fed back to the input to overcome circuit losses and to start and sustain oscillation. A tuned circuit is incorporated in either the plate or grid circuits (or both) to establish the operating frequency. The operation of a vacuum-tube oscillator is similar to that of a spark-gap unit, but with a vacuum tube replacing the spark-gap as a source of power pulses. However, the high frequency output is obtained as a continuous wave rather than as a series of pulses with a comparatively low repetition rate. Vacuum-tube power oscillators are used at frequencies of from 150 kc. to one mc. and higher. Commercial units are available with power ratings from a few hundred watts to hundreds of kilowatts. Epimetheus and Prometheus were assigned the task of providing man and animals with faculties necessary for their preservation. Epimetheus was to do the actual fitting, with Prometheus supervising. Claws were bestowed to one animal, protective armor to another, and wings, fangs, and special coloring to others. But when Epimetheus came to man, he had exhausted his store of gifts and his orders had been to make man superior to all creatures. When Prometheus learned of this, he went to heaven to light his torch at the chariot of the sun and he brought fire to mankind. Zeus was enraged for man was now able to do things which had only been done by gods. And Prometheus was bound to a rocky cliff for all eternity because he dared to bring the power of fire to man. - Greek Mythology Induction Heater Applications Induction heaters are used in the metal working industries and for soldering the seals of canned foods, hardening machine parts, annealing sheet metal products, brazing fittings, and melting small lots of metals in laboratories developing new alloys. In many cases induction heaters are used to supplement other heating techniques or to do a job faster and more efficiently than older methods. However, induction heating is frequently used in applications where no other heating method has been completely satisfactory. One example of this type of application is in vacuum heating and melting, where metals are processed in a vacuum. Another example is in the vacuum-tube manufacturing industry. During the evacuation process, the metal elements of vacuum tubes must be heated to high temperatures to drive out gases which might later shorten the service life of the completed tube. Since the tube electrodes are surrounded by a glass envelope, a direct method of heating is not practical, but induction heating may be used when the coil is placed around the outside of the tube's envelope. Many present-day applications of induction heaters seem almost like "black magic." A person can place his hand in some types of induction furnaces and, if the furnace were not charged with a load of metal and if he wore no ring, he would feel no heat. Yet this same furnace could melt a piece of steel in minutes. One problem in melting some types of metals is finding a furnace lining which will not melt itself under the intense temperature. With induction heating it is possible to float a "charge" of metal in mid-air during the heating and melting process, then to release the melted ball at will! This has already been accomplished in laboratory experiments.

Ajax TOCCO video

Posted August 5, 2019 |

|